In his opening remarks at ARC Advisory Group’s recent Industry Forum in Orlando, Florida, ARC President, Andy

An entire Forum session focused on IT/OT/ET convergence. Speakers from Eli Lilly and Danfoss shared their real-world IT/OT/ET convergence stories. However, as demonstrated in the panel discussion, the audience was not entirely convinced that full convergence is happening.

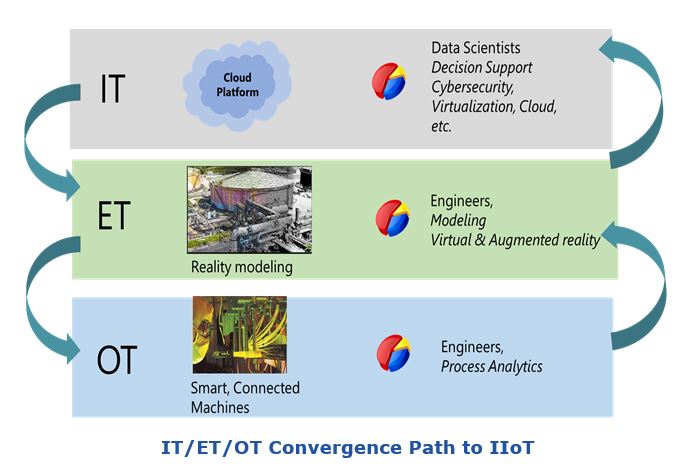

ARC Sr. Analyst, Paula Hollywood, kicked off the session by stating that IT/OT convergence has become accepted practice in the manufacturing industries. The increased sophistication of intelligent devices and associated software drive the need for tighter integration of the IT and OT domains to gain new insight from known information. However, in

the digital data environment of IIoT, engineering technology, those technologies that create virtual models must be included in the convergence conversation. While inclusion of ET may have been implied in the past, its use in the current and future work environment cannot be underestimated as modeling tools become essential to managerial or technical decision making.

In model format, Ms. Hollywood believes that ET lies in the middle of IT and IT as ET utilizes IT to improve OT. As technologies to capture and visualize real-world conditions continue to improve, ET provides users with the ability to better understand assets in context. The relationship among these domains must go beyond “peaceful co-existence.” It must coalesce into something that is ultimately greater than the sum of the parts.

Designing and testing new products, systems, and even plants in a virtual environment makes a compelling case, particularly from a cost perspective. Virtual models can tie these domains together over the lifecycle of asset. From an asset management perspective, it’s about predicting a problem before it occurs and enabling maintenance to be performed at optimum rates and costs.

According to Kevin Wilhelm, Corporate Automation Engineering at Eli Lilly, convergence began 20 years ago as open systems such as those in the consumer marketplace began to replace the closed, proprietary systems commonly found in the industrial marketplace. From Mr. Wilhelm’s perspective, we’re still in the early stages of computing technology adoption despite what he described as a million-fold increase in engineering capabilities over the last 30 years.

The pharmaceutical industry has a reputation of being change averse due to the validation requirement for manufacturing processes. However, Wilhelm says that’s a myth. He makes changes every day, but follows change control procedures that are guided by disciplined engineering practices in applying manufacturing IT to automation to ensure consistency in expected results. In addition to investment in new technology, Mr. Wilhelm would like to see investments in people and processes to ensure that all advance at the same rate.

It’s easy to understand why Wilhelm is passionate about planning for obsolescence. He shared a real-world example of IT/OT/ET converging at Lilly. An HMI graphics card needed replacement due to a defective component. The replacement card required a driver that was incompatible with the existing version of Windows in that operation. A Windows upgrade would affect other applications. In this case, the obsolescence of a single component on a graphics card cascaded into a project to upgrade the HMI and all other affected applications and interfaces. This seemingly simple issue required extensive IT/OT/ET collaboration to solve.

Most readers have been to the supermarket at some time in their lives, but have you ever thought about how those facilities operate? Like the process industries, food retail is energy intensive – it takes a lot of electricity to operate the refrigeration equipment required to ensure the safety of the food we buy. According to Rick Ruth, Product Manager at Danfoss Services, supermarkets gross profit average just 2 percent, not much. Given such tight margins, individual stores are hard pressed to justify full-time maintenance staffs. So, how does your favorite supermarket keep its refrigeration equipment from failing, and can a supermarket become a net-zero building?

In his presentation, Mr. Ruth shared an IT/OT/ET convergence story that has spawned a whole new service business

Bentley Systems’ AssetWise solution provided Danfoss with the operational analytic and visualization capabilities for Smart Store to centralize data generated from various sources and displayed on dashboards. With Smart Store, Danfoss monitors store equipment remotely and advises its customer when an asset requires attention. Alarm management helps ensure food safety and minimize food loss. Load shedding reduces energy consumption. Continuously monitored refrigeration equipment anticipates failure. Alarm filtering helps clarify false alarms from real maintenance needs. Danfoss claims to implement the system to more than 9,000 stores to date globally with up to 50 percent energy savings per store.

The audience was not entirely convinced that convergence is happening as evidenced when the panel was asked to cite specific examples of convergence in their organizations. According to Ruth, convergence is taking shape at Danfoss due in large part to cloud computing-enabled collaboration, but conceded that full convergence would take another four to five years. Currently, he stated IT is involved in the security aspects of Smart Store and reporting at the facility layer. At Eli Lilly, Wilhelm stated that the vice presidents of manufacturing IT and engineering collaborate to ensure their agendas are aligned specifically around asset information management as Lilly applies the cloud to automation. Panelist Paul Casto, GE Digital, offered thickness measurements as an example in which field measurement data is integrated with engineering information and how operations teams use this information to plan maintenance. Panelist Phil Niccolls, Emerson Automation Solutions, said the degree of convergence is reflective of an organization’s IIoT maturity.

Russell Viciedo of Tata Consultancy Services expressed a dissenting opinion. He stated that the lack of alignment in corporate strategy results in continued silo building. Without alignment at the executive level, Mr. Viciedo believes that the capability to integrate later in the project is diminished. In his opinion, as long as this situation persists, true convergence will not be attainable. Panelist Jim Newman, Bentley Systems, offered that many executives have not yet grasped the value of doing things differently. ARC’s Hollywood suggested that convergence is likely occurring more on an informal rather than formal basis at this point in time.

Software-defined equipment has been the driver of IT/OT convergence. Based on the panel discussion, ET is slowly gaining entry to the convergence conversation. However, engineering models often remain stranded in information silos, inhibiting the ability to leverage this information to optimize manufacturing operations.

IIoT is driving convergence among IT, OT, and ET domains. Full convergence offers the benefits of data context and clarity as well as the ability to continuously optimize the process. The ability to leverage digital engineering models with visual representations of process operations aids the decision-making process, not just in the design phase, but over the lifecycle of the asset. Consolidating these once disparate domains also offers opportunities to better manage risk, more accurate financial planning, and make for a safer working environment.

As discussed by the panel, IT/OT/ET convergence will not compensate for the lack of well-defined strategies. Strategy development as well as its clear communication throughout the organization is the responsibility of executive management. Clearly stated objectives are the foundation of a collaborative environment to enable the organization to develop work processes to achieve the goals.

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Convergence, Engineering Technology (ET), Information Technology (IT), Operational Technology (OT), ARC Advisory Group.