Keywords: Sustainability, Energy Savings, Energy Efficiency, Sustainability, ARC Forum, GHG Emissions, AI, Analytics, IoT, ARC Advisory Group.

ARC’s recent European Industry Forum (EIF) offered a wide variety of presentations and workshops on strategies and case studies in line with this year’s theme of Managing Industry Evolution in Times of Global Disruption. The session on Sustainability covered a variety of topics ranging from energy optimization using data analytics to sustainable automation.

This report discusses presentations given during the Sustainability as a Business Strategy session at EIF. ARC invited industrial automation technology experts to speak about sustainability and its status, trends, industrial challenges, use cases, and technology offerings. The session included a case study from heavy industry and the importance of automation technologies for achieving sustainability goals. Sustainability is changing operations, and the adoption of digital transformation is essential for companies to reach their sustainability goals.

Sustainability is now one of the leading growth drivers for the automation marketplace, and many end users are implementing advanced sustainability strategies and frameworks. It is a good sign to see that organizations are taking sustainability seriously and ARC sees sustainability as a key objective. The increasingly stringent regulatory environment is further driving industrial companies to achieve their sustainability goals.

Team lead for data science at Wienerberger AG Florian Zittmayr presented a case story on implementing energy optimization for heavy industry applications using data analytics. Wienerberger, a major building materials provider for the entire building envelope, is the world’s largest brick manufacturer, and is one of the leading pipe system suppliers in Europe.

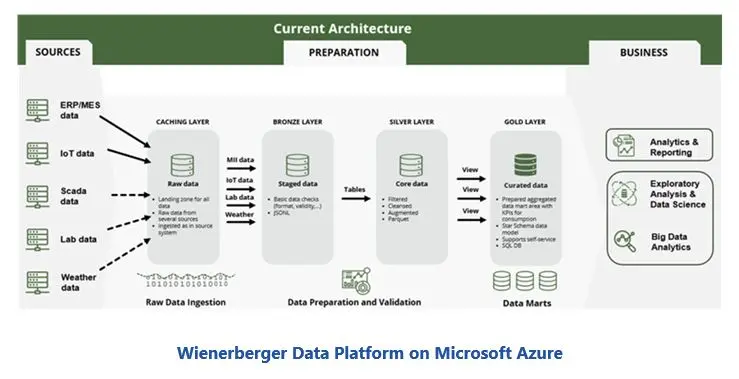

Wienerberger turned to AI and IoT analytics from SAS, running SAS Viya on Microsoft Azure Cloud, to help optimize energy costs and achieve its ambitious sustainability goals. The company aims to reduce emissions by 15 percent in 2023 compared to 2020 and has the goal of being completely climate-neutral by 2050.

A factory in Poland was selected for an initial project. The plant has become one of Wienerberger’s best-performing plants, and the successful project now serves as a template for expanding the use of AI to other facilities. The collected data from a wide range of sources revealed fluctuations that can lead to inefficiencies and unnecessary energy use. With kilns for firing bricks running at 800° C, the goal is to reduce variability to find ideal, repeatable production steps.

SAS and Wienerberger also developed an AI-powered digital twin of the brick production processes that helps explain the fluctuations. The digital twin also offers insights into changes that can lower energy use, improve product quality, and reduce emissions. By optimizing energy consumption and reducing CO2 emissions through SAS AI and IoT analytics, Wienerberger is turning brick plants into data-driven factories. The aim is to expand the use of advanced analytics in the cloud across 149 facilities in 23 countries.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Here, you can learn more about the Process Simulation and Optimization Market.