Keywords: Asset Performance Management, Process Optimization, Scaled Agile Framework, IT-OT Convergence, ARC Advisory Group.

Many process manufacturing enterprises need help to apply artificial intelligence (AI) and machine learning tools to improve asset performance. ARC Advisory Group’s research identifies that while condition-based maintenance is most prevalent, leaders have successfully built the AI capability to improve asset performance practices through in-house platforms, commercial solutions, and a combination thereof. Today, a small percentage of users leverage AI to identify maintenance and process issues and expand the scope of their traditional maintenance practices.

AI functionality in asset performance strategy provides early warning to minimize process interruptions, information to adjust the process, and ensures the right assets are available to match the performance goals of the plant. Most companies use internal data science teams and in-house platforms to develop AI capabilities. This approach, however, comes with the price of higher technical debt.

Asset performance strategy focuses on maximizing reliability, process efficiency, and achieving the best possible return on investment from the assets. In the past, users supplemented the strategy with rudimentary real-time data collection and seldom involved IT. A broader skill set is required to link a proactive asset performance strategy with AI/ML, achieved through Scaled Agile Framework (SAFe). SAFe addresses the challenges of procuring multiple commercial AI/ML solutions and integrates these into internal platforms, reducing technical debt and improving interoperability.

ARC Advisory Group recently conducted research to gain a better understanding of how process manufacturing industry leaders are using Artificial Intelligence (AI) and machine learning tools to improve uptime, process health, and return on assets. A global web survey of 155 experts and in-depth discussions with several subject matter experts (SMEs) across different industries identified compelling best practices and reasons for industrial organizations to rethink their current approaches to AI.

While condition monitoring and rules-based tools were most prevalent in the industry, we found 63 percent of industrial process company respondents have a program in place to improve asset performance using advanced analytics and AI. Of those surveyed, 25 percent claim they can use AI to detect failures and generate maintenance alerts. However, 16 percent use AI and machine learning models to identify and address maintenance or process issues to avoid disruptions, thereby expanding the scope of asset performance strategy from traditional maintenance practices.

We also surveyed users to determine which functional organizations use the output of current asset management tools, and the results were alarming. 36 percent of users claim the Internal IT or Data Science organizations use the output of advanced tools like AI and machine learning and only 13 percent of maintenance and operations organizations benefit from current AI tools.

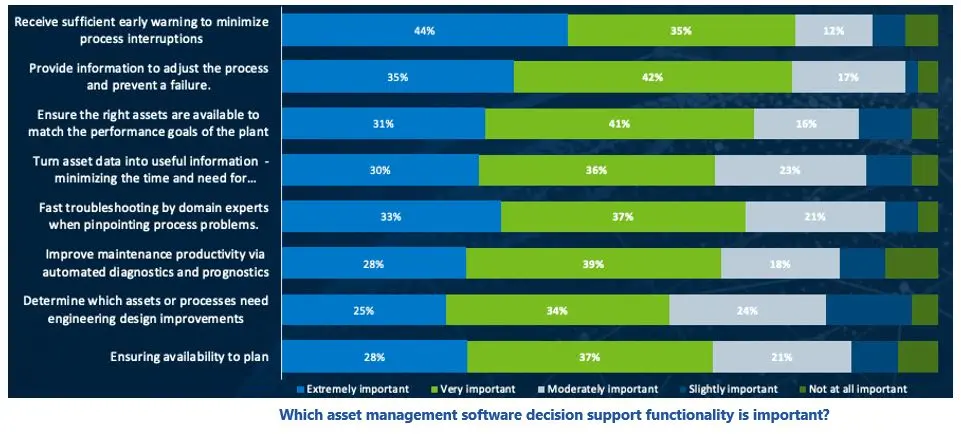

The survey results show a high maturity level in understanding the capability of AI tools. Users understand the importance of modern tools for leveraging data insights across various functional roles, spanning from maintenance and reliability to operations to improve asset performance. In order of importance, the top three software functionality needs were:

Receive early warnings to minimize process interruptions.

Provide information to adjust the process and prevent failures.

Ensure the right assets are available to match the performance goals of the plant.

Oleoducto de Crudos Pesados (OCP) Ecuador is a midstream oil and gas company that transports, stores, and ships crude oil. The company prides itself on providing reliable, safe, efficient, and environmentally committed crude oil transportation operations, with a capacity to transport 450-517K barrels/day from the Amazon to the marine terminal in coastal province of Esmeraldas. As the country’s production fell, OCP Ecuador was forced to operate its facilities at reduced capacity (just 30- 50 percent of maximum capacity) while ensuring reliability of spare assets. However, transportation fees and tariffs are typically fixed for pipeline companies regardless of utilization.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

You can learn more about APM at Asset Performance Management Market Analysis Research