Keywords: IT, OT, ET, IIoT, Operations, Engineering, Maintenance, Convergence, Digital Transformation, Center of Excellence (COE), Petrobras, Digital Transformation, ARC Advisory Group.

Petrobras is a Brazilian government-controlled multinational energy company. It is one of the largest integrated energy companies in the world, involved in various aspects of the oil and gas industry, including exploration, production, refining, and distribution. The company has significant offshore oil and gas reserves in the pre-salt fields (deepwater oil fields located beneath a thick layer of salt in the Atlantic Ocean off the Brazilian coast) located in the Santos Basin, which are a major source of production.

Pedro Vieira, Manager at Petrobras, recently discussed with ARC how the company is leveraging digital technologies to improve efficiency, optimize operations, reduce costs, and enhance safety and environmental performance. The company is transforming digitally and implementing initiatives to increase its environmental and sustainability performance, which includes investments in renewable energy (biofuels and wind projects) to reduce greenhouse gas emissions. Petrobras is pursuing digital transformation initiatives to enhance its operations and optimize its business processes by enhancing the use of data analytics and AI, modeling, simulation, asset reliability, and digital engineering. They are leveraging IoT devices and sensors for operations, offshore platforms and pipelines. Digital twin technology is being utilized to replicate physical assets, and industrial cybersecurity cloud computing to facilitate collaboration, streamline operations, enhance ability, and reduce manual work. The company is also integrating other technologies to increase its innovation, agility, and availability.

The motivation for Petrobras’ IT (Information Technology), OT (Operational Technology), and ET (Engineering Technology) convergence is to optimize and streamline its operations, increase efficiency, reduce costs, and drive innovation. By integrating IT-OT-ET technologies, Petrobras can improve real-time data collection, predictive maintenance, production planning, supply chain management and logistics. Integration of the data will also provide Petrobras workers with better data for actionable decisions.

Petrobras implemented its IIoT Center of Excellence (CoE) to help resolve some of the challenges they are facing. The IIoT CoE will allow them to decrease costs by increasing their exploration success rate; decreasing exploration, project, and construction times; have faster and lower-cost supply and logistics, improve productivity, minimize unplanned operations downtime, and for top-quality engineering designs. Integration challenges include the ability to perform cross-discipline integration, improve external supply and delivery integration, and decrease vendor technology dependency. The CoE will also improve safety and security by improving HSE performance and increasing asset security (cybersecurity). Business improvements result from more accurate and agile decision-making, improved leadership, and workforce training, which will enable a more efficient business change management model for faster repositioning.

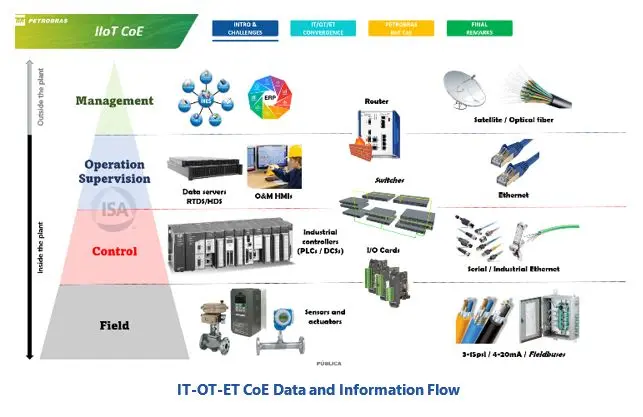

Mr. Vieira described how Petrobras divided IIoT into layers that resemble the traditional S88 and S95 models. The IT-OT-ET layers include field, control, operations and supervision, and management layers. The field layer includes the sensors and actuators; the control level includes the industrial controllers, (PLC, DCSs), and data servers. At the operations supervision level there are servers (RTDs/HDs), and human machine interfaces (HMIs). The management level includes the MES and ERP systems. The control and field layers are integrated by I/O cards, and the control and operation supervision levels are connected by the switches, and the operation and management level are connected using routers, firewalls, and Ethernet.

In the field, digital fieldbuses or 4-20 mA electric signals – or, in older plants, even pneumatic cables using 3- 15 psig – are used to connect sensors and transmitters to the control system. At the control level, serial, and industrial Ethernet connections like Modbus, Profibus, and other protocols are used for the connections.

At the operational and supervisory level, Ethernet and switches are used. Satellite and optical fibers are used for telecommunications at the management level. The IT team is responsible for the MES, ERP, routers, and Ethernet.

Having data standards and an understanding of how data and information flow from and to the plant are important. “It is important to have access to the data. Data flows are important. The problem is that there are still data silos in plants and multiple protocols between all levels.” According to Mr. Vieira, it is often difficult to gain access to data in silos.

“Data needs to be accessible and available, and the plant data needs to be standardized so that actionable information is sent to the engineers and operators for collaboration and so that they know what action(s) to take. The problem is that there are still data silos in many plants and multiple protocols between all layers in the plant.” This is why integration and protocol standards are so critical for success. Over the years, Petrobras has made investments in data, but sometimes the data failed to deliver a full or tangible return on investments because it was not connected.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Obtain more ARC In-depth Research at Market Analysis