Keywords: Digital Transformation, Life Sciences, Pharmaceutical, Pharma, Biotech, Medical Devices, Paperless Manufacturing, Integration Platforms, Digital Twins, Siemens, ARC Advisory Group.

Siemens recently briefed ARC on its life science digitalization portfolio and overall strategy for life sciences. Siemens maintains a dedicated team for life sciences with multiple centers of excellence in countries across the globe with extensive domain and technology expertise to support clients. Siemens works together with its partners and clients to accelerate digital transformation in  life sciences and co-create new solutions.

life sciences and co-create new solutions.

While the life sciences industries have always been important to Siemens, today, the company is particularly focused on this industry as evidenced by its portfolio, technology and strategy. This report describes Siemens’ end-to-end life sciences solutions that are implemented globally in the pharmaceutical, biotech, and medical device industries.

Siemens’ solutions comprise automation and digitalization technologies designed to work in research, design, and production for small to large molecules, for blood fractionation, in primary and secondary production, small and large production, and in process and hybrid manufacturing. The company’s life science solutions address key requirements and encompass paperless manufacturing, cloud computing, digital twins, and asset performance. The solutions extend from the pharmaceutical and biotech industries to the medical device industry. Their products and services evolve around the entire life science value chain. Additionally, Siemens facilitates co-creation and collaboration between an ecosystem of partners, customers, and developers for innovative solutions to problems that combine its expertise and technology.

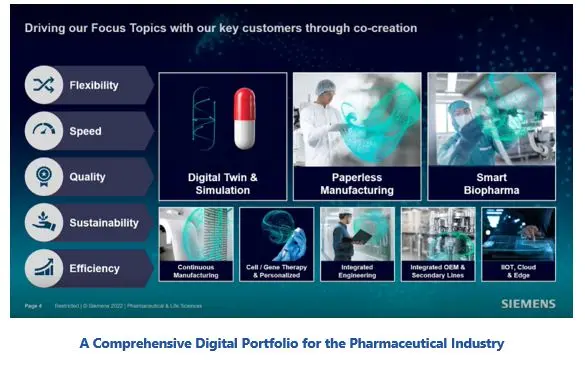

The Siemens portfolio and strategy address continuous manufacturing, cell/gene therapy and personalized medicine, integrated engineering, integrated OEM and secondary lines and IIoT, as well as cloud and edge computing. They address five key life sciences market drivers: flexibility, speed-to-market, quality, sustainability, and efficiency. The company’s offering incorporates digital twins and simulation, paperless manufacturing and smart biopharma, while the digital twin and simulation portfolio encompasses equipment, machines, and processes. The paperless manufacturing focus is on producing products in a paperless manufacturing environment. Smart Biopharma encompasses the commissioning, building, and engineering of flexible, modular factories and lines, also enabling the plug & play of single use technologies.

Products for life sciences include key technologies:

A modular portfolio of software and IoT-enabled hardware that can help companies with their digital transformation.

Siemens Xcelerator: an open, flexible, low code-no code open business platform and a broad range of services from Siemens and certified third parties.

End-to-end digital portfolio and digital transformation strategy and portfolio for maximizing operations and performance.

New technologies and services that range from digital twins to paperless manufacturing, blockchain and traceability, digital recipe enterprise management, and new platforms for integration.

Enterprise Recipe Management for linking R&D to manufacturing and optimizing tech transfer.

A growing ecosystem of collaborative partners, from solution vendors and academia to technology partners.

A marketplace to explore, educate, exchange and execute with a community of customers, partners, and developers.

Life sciences is one of the most conservative industries, but the paradox is that it is innovative, with significantly higher levels of R&D spending compared to other major industries. However, the industry takes a conservative approach to the implementation of new digital technologies in manufacturing. The recent pandemic accelerated digital transformation initiatives particularly in  pharma and biopharma, partly because there was more funding and high-level visibility in manufacturing. The ability to accelerate time-to-market became more important during the pandemic.

pharma and biopharma, partly because there was more funding and high-level visibility in manufacturing. The ability to accelerate time-to-market became more important during the pandemic.

The enhanced collaborative environment that existed during the pandemic enabled the sharing of knowledge within the industry because of the synergistic effort to find therapeutics and vaccines that worked for COVID. Digital transformation was an enabler in finding a solution. Life sciences managers approved initiatives, technology and projects that may never have received approval in the past, which helped to accelerate the industry’s adoption of new digital technologies. Although the pandemic has ended, life science companies will continue to invest in and use their pandemic knowledge and technologies, thanks to the new mindset in terms of how technology and collaboration can accelerate innovation.

Siemens’ vision for life sciences is about winning the race against time with platforms, technologies, services, and strategies to address key industry concerns: flexibility, real-time release, collaboration, individualized production, connected equipment, and big data. Siemens’ end-to-end strategy and portfolio focus on accelerating development and manufacturing of the entire life sciences value chain from molecular development, continuing with the cell line and process development, and on to upstream and downstream production and the fill and finish lines.

Siemens offers a comprehensive digital portfolio that brings together end-to-end solutions from design and simulation products and processes, production efficiency solutions, planning, simulation, and predictive production and operate and monitoring solutions using an infrastructure. These are not single point solutions; instead, they can be connected to form a holistic, digitized system using common data. The offering includes capabilities for process design with mechanistic modeling, 3D material simulation, product lifecycle management, and quality by design (QbD).

The planning, simulation and optimization of production includes integrated plant engineering, operator training simulators (OTS), plant design and layout, and machine design solutions. The production efficiency and security solutions include electronic batch recording, dashboarding, automation & control and transparent operations and analytics. Operate and monitoring includes integrated building management platform solutions, environmental monitoring, integrated security for critical infrastructure solutions, plant and room automation and field devices, and fire protection systems.

While cloud, IoT, and edge form the cornerstone of Siemens’ life sciences technology, the ability to integrate data from systems and OEM equipment in primary, secondary and R&D facilities; or end-to-end is due to the company’s open, digital platform called Xcelerator. Xcelerator is designed to accelerate client’s digital transformation by enabling the efficiency, resiliency, flexibility, user experience and sustainability needed for scalability and faster time-to-market. Xcelerator supports the integration of data from the shop floor to the top floor.

Tech transfer of product recipes is often a bottleneck in the life sciences’ industry and often prevents the industry from meeting  key performance indicators (KPI). One tech transfer bottleneck is that companies lack a data model, or a way to move the data from a site to a general recipe that can consider all the different characteristics and variants from each recipe from each product, department, or site.

key performance indicators (KPI). One tech transfer bottleneck is that companies lack a data model, or a way to move the data from a site to a general recipe that can consider all the different characteristics and variants from each recipe from each product, department, or site.

Siemens’ Enterprise Recipe Management helps clients solve the tech transfers bottleneck by transferring recipes and formulation, from development through the entire value chain, to meet KPIs quickly. By using the Recipe Management Solution, clients can use the data model with all its characteristics and variants and enable a tech transfer that closes the gap within the product lifecycle.

During the pandemic, Siemens’ digital twin and simulation solutions were used on new vaccine production lines to increase throughput, reduce waste and bring COVID therapeutics to market faster. Siemens offers a comprehensive set of simulation tools that allows users to build a digital twin for pharma to discover optimized designs for products, equipment, and processes faster. The digital twin solution includes digital twins of machine operation, virtual commissioning, processes, and machines.

Developing vaccines has historically been a time-consuming process, often taking more than a decade. This is partly because there are so many different phases involved in saving lives. Digital process twins can accelerate vaccine development by shortening vaccine development processes, reducing raw materials waste, increasing yields, and simulating manufacturing processes.

The reasons that traditional vaccine development takes so long are 1) lack of a digital connection, 2) long development times for manufacturing processes, and 3) the robust in-human clinical trials and documentation required to evaluate safety and efficacy for the regulatory filing and approvals. By working with digitalization, GlaxoSmithKline (GSK) worked with Siemens and Atos to deploy new technology to digitally transform each phase of vaccine development and production. They piloted Siemens digital twin, with a complete and real-time simulation of the vaccine manufacturing process to expedite vaccine development.

GSK uses Siemens’ digital twin technology to accelerate its vaccine development process. After successful completion of a proof-of-concept project that focused on the production of particles of a vaccine adjuvant, GSK began implementing digital twins into other development activities. The company plans to explore using digital twins for vaccine R&D as a way to reduce experimentation efforts and help developers improve sustainability as fewer materials and less energy are consumed.

Siemens works with an ecosystem of strategic partners, OEMs, academia and other organizations to deliver innovative life sciences solutions to its customers. For example:

For module type package (MTP) and plug & play solutions, Siemens works in partnership with Sartorius, using the company’s automation platform to integrate equipment and to configure and develop the company’s engineering platform for BioBrain. According to BioBrain, the platform offers powerful development tools, and their flexibility enables integration with different equipment.

Siemens works with Exyte on pre-built and scalable modular biotech facilities (MTP) and clean rooms using end-to-end solutions for cell and gene therapy manufacturing with integrated power, building, and automation solutions.

CPI collaborates with Siemens and academia in its medicine manufacturing innovation center, which was partly funded by the UK government, GSK and AstraZeneca, with Siemens as technology partner. CPI leverages Siemens digital twin to engineer the plant layout and identify bottlenecks for paperless manufacturing by developing a QA dashboard for real-time release of production based on MES data.

Siemens offers a comprehensive, end-to-end life sciences portfolio of technologies, services and strategies that helps clients digitally transform while meeting regulatory compliance. Using these solutions, end users can discover better designs faster, engineer faster with virtual commissioning, train operators, and optimize operations. Siemens integrates its solutions in life sciences and helps to foster collaboration among clients’ business units, academia, and other industry partners. The Siemens open ecosystem combines knowledge and expertise with a strategy and vision that will provide new innovations in the life sciences industry. Siemens plans to continue developing life sciences portfolio solutions through internal development or from acquisitions and will continue to collaborate to accelerate the digital transformation and speed-to-market strategy.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Obtain more ARC In-depth Research at Market Analysis