Keywords: Asset Management, Asset Performance Management (APM), Reliability, Maintenance, Honeywell, Analytics, Artificial Intelligence (AI), Machine Learning (ML), Outcome-based Objectives, Cloud Computing, ARC Advisory Group.

In the capital-intensive process industries, it is crucial for owners/operators to maintain their assets, machinery, and equipment  well. Proper care and management of these assets is needed to ensure that plants operate efficiently, reliably, and safely. Owners/operators are paying even more attention to asset performance management (APM) as they realize its role in improving profitability and as a means of achieving business goals. Honeywell’s unified asset management platform and outcome-based asset management offerings provide owners/operators with end-to-end solutions that help them address their major asset management challenges and directly tie in with their leading business objectives.

well. Proper care and management of these assets is needed to ensure that plants operate efficiently, reliably, and safely. Owners/operators are paying even more attention to asset performance management (APM) as they realize its role in improving profitability and as a means of achieving business goals. Honeywell’s unified asset management platform and outcome-based asset management offerings provide owners/operators with end-to-end solutions that help them address their major asset management challenges and directly tie in with their leading business objectives.

Owners/operators have long realized the benefits of effective APM practices and leveraged several of the traditional reliability, condition monitoring, maintenance management tools to ensure the reliability and availability of their critical assets. However, many owners/operators still have a siloed APM approach, where different systems do not integrate with one another, leading to highly ineffective APM practices. Many end users are also heavily reliant on subject matter experts to run their maintenance programs efficiently. As boomers continue to retire, most industries struggle to fill the skills gap. Owners/operators have limited resources, while manual labor, processes, and software update requirements further add to their APM challenges. New APM technologies, when curated carefully and combined with traditional asset management practices, can help users achieve transformative advances in reliability, maintenance execution, and business performance.

The Honeywell team including Product Directors R. Ilangovan and Praveen Sam recently briefed ARC Advisory Group analysts on how the company’s new outcome-based offerings for asset management leverage advanced digital technologies to offer owners/operators complete end-to-end APM solutions. The company’s leading division, Honeywell Connected Enterprise (HCE), continues to enhance its Honeywell Forge Performance+ for Industrials solutions line to help owners/operators optimize performance, sustainability, and safety at the enterprise level for better business outcomes.

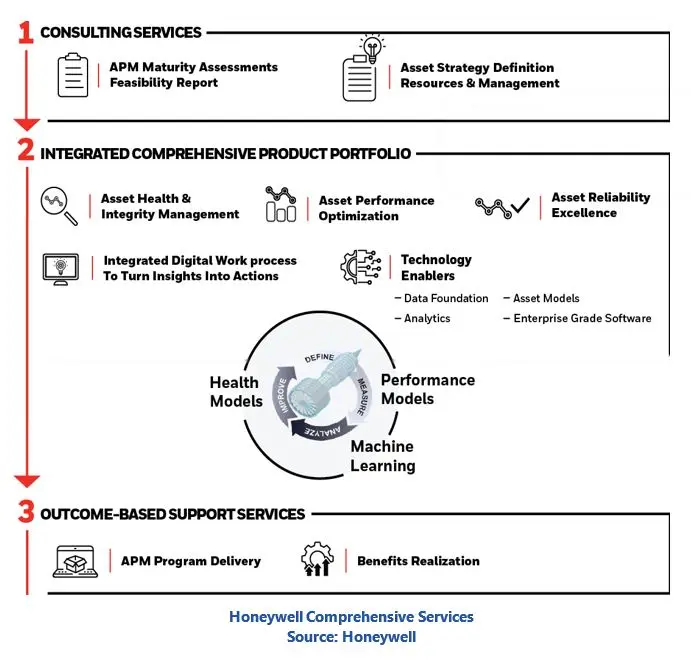

New features, products, and services by the company have been focused on offering users a complete end-to-end APM solution. Owners/operators have long struggled to connect disparate solutions and devise their asset management strategy on their own. Honeywell’s approach to help them from the beginning and throughout the asset journey at various steps with integrated comprehensive solutions, a unified APM platform and outcome-based support services, aims at simplifying asset management for the owners/operators. According to the company, their unified platform approach to APM takes asset management to the next level as it leverages information in owners/operators’ various siloed systems to present insights to users and create a closed-loop process.

ARC research has revealed that having a sole focus on the technology yields limited results when it comes to asset management. Instead, owners/operators should focus on an overall APM strategy. They should include detailed APM, and reliability plans and consider assessments and asset strategy. Owners/operators often overlook this most important starting step, and Honeywell, with the aim to simplify this step for owners/operators, offers a comprehensive programmatic approach to reliability with its value-focused reliability consulting services. These services, focused on APM maturity assessments and strategy development, establish a strong foundation for companies’ end-to-end reliability offerings and provide a path to success for APM initiatives.

The skills gap has become a major challenge for the industrial world. Owners/operators are looking at technology to help them address this widening gap. Honeywell’s APM solutions offer asset models embedded with domain expertise for instruments and various types of assets including rotatory, static, electric, and mobile. The asset model library, built on Honeywell’s expertise and based on industry standards, is available out of the box to help users reduce asset configuration time.

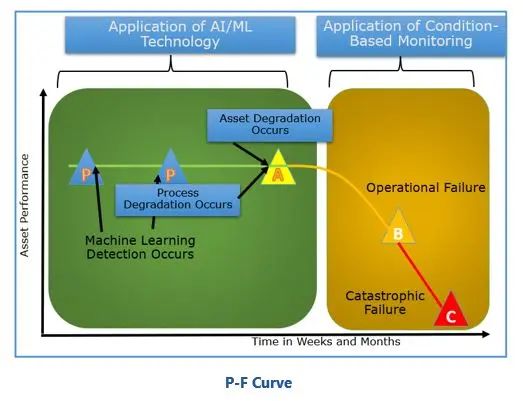

Honeywell’s APM solution also offers predictive analytics capabilities. According to the company, its flexible analytics platform  combines first principle thermodynamic models, rule-based heuristics, and AI/ML into a single solution to offer owners/operators early insights into asset health so that users can make better informed decisions to maintain their assets. According to ARC Advisory Group research, one of the major benefits of predictive analytics and ML technology is early detection of potential equipment failure. By employing advanced modeling and ML technologies, Honeywell APM solutions analyze hundreds of process parameters over time, as well as compare these to historical asset data. This helps improve lead times for maintenance and operations staff. The solutions also provide users better insights so they can address issues effectively to avoid imminent asset failures. By embedding the knowledge of its many subject matter experts into its models, Honeywell has essentially democratized analytics for use by engineers rather than data scientists.

combines first principle thermodynamic models, rule-based heuristics, and AI/ML into a single solution to offer owners/operators early insights into asset health so that users can make better informed decisions to maintain their assets. According to ARC Advisory Group research, one of the major benefits of predictive analytics and ML technology is early detection of potential equipment failure. By employing advanced modeling and ML technologies, Honeywell APM solutions analyze hundreds of process parameters over time, as well as compare these to historical asset data. This helps improve lead times for maintenance and operations staff. The solutions also provide users better insights so they can address issues effectively to avoid imminent asset failures. By embedding the knowledge of its many subject matter experts into its models, Honeywell has essentially democratized analytics for use by engineers rather than data scientists.

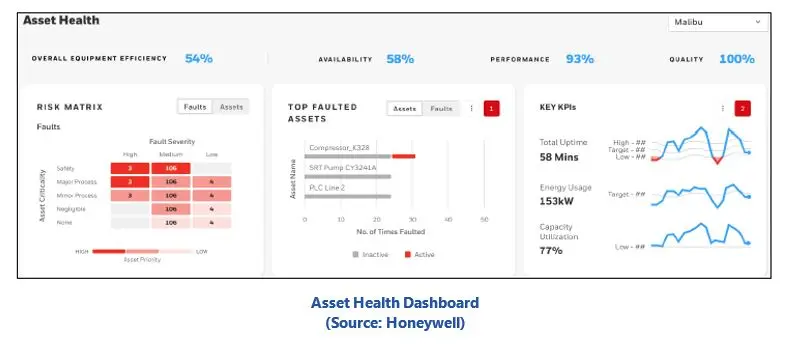

Another major challenge for owners/operators is that they have multiple systems with each system storing data in its own database. They have legacy and custom homegrown systems, machines, spreadsheets and other data sources in data silos. As a result, the ability to collaborate, scale, leverage data from all these data sources and garner asset insights continues to remain a challenge for many users. This siloed approach over time becomes more isolated, complicated, and difficult to support. Honeywell addresses this major challenge by offering a unified asset management platform that supports enterprise level scaling with out-of-the-box connectors for multiple OT applications. The platform integrates with existing siloed condition monitoring systems into a single system to bring in key data related to asset health, integrity, efficiency and energy performance in one system. Furthermore, the solution offers easy workorder integration to help align operations strategy with maintenance strategy and create a closed-loop process.

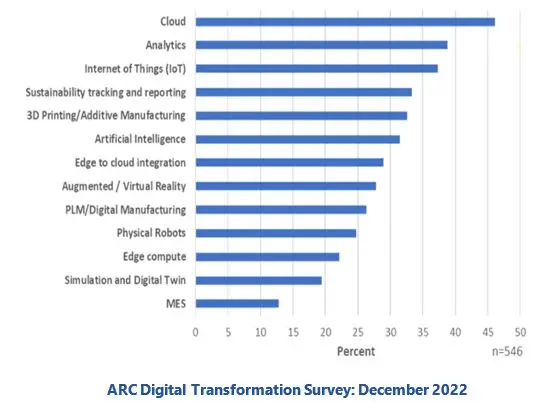

While Honeywell has delivered on-premises solutions for many years, with Honeywell Forge Performance+ for Industrials | Asset  Performance, the company now offers a native-cloud deployed solution. Cloud deployment offers many benefits to owners/operators; it helps reduce the operational cost and complexity for owners/operators and adds flexibility and scalability. Most owners/operators are looking to leverage Cloud benefits. ARC’s Digital Transformation Survey highlighted that nearly half of the manufacturers were on track to implement Cloud technology completely in at least one of their plants by 2026.

Performance, the company now offers a native-cloud deployed solution. Cloud deployment offers many benefits to owners/operators; it helps reduce the operational cost and complexity for owners/operators and adds flexibility and scalability. Most owners/operators are looking to leverage Cloud benefits. ARC’s Digital Transformation Survey highlighted that nearly half of the manufacturers were on track to implement Cloud technology completely in at least one of their plants by 2026.

Honeywell’s SaaS-based asset performance solution offers faster and more scalable deployment. The solution’s enterprise-level integration ensures cross-functional collaboration. With enhanced service management, owners/operators do not need to worry about software updates.

Owners/operators have long understood the importance of asset management. The scope, however, was limited with focus only on maintenance. With newer technologies, the definition of APM has evolved with increasing attention on APM’s role in achieving business objectives.

With its outcome-based solutions, Honeywell is moving beyond technical specifications, features, and short-term benefits. The company, working in close collaboration with owners/operators, is striving to ensure that users achieve expected outcomes and realize long-term success. With this approach, Honeywell works with owners/operators from the beginning and takes the time to understand their needs, challenges, and priorities to leverage the insight and deliver value and desired results. This outcome-centric mindset helps customers operationalize, scale, and sustain their asset management program. With its years of experience and deep domain knowledge, Honeywell is in an excellent position to help industrial organizations improve their asset management programs and achieve desired business outcomes.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

You can learn more about APM at Asset Performance Management Market Analysis Research.