To provide our Advisory Service clients with holistic coverage of the various industrial and automation markets we cover, ARC Advisory Group publishes every quarter indices on automation, machinery and user CapEx markets as a Special Report in PowerPoint format. This concise report focuses more on the quantitative than the qualitative aspects of the markets.

This report also covers a special topic: “Black Swans.”

It can turn ugly, maybe even nuclear, it can disrupt supply chains, lead to rising food prices, which in turn have caused mass protests and civil unrests in the past.

Against Taiwan and other states in the South China Sea can turn the whole region into chaos, far more than what we have seen with the Russian invasion into Ukraine.

While most countries and recently even China have loosened their COVID vigilance, there is still the threat of a new possibly deadly mutation, which can lead to health, social, and economic disruption.

A combination of a dark, cold, windless, long winter, and issues in LNG terminals can cause not only higher prices, but outages and production being shut down due to energy availability.

It is hard to predict how and if the supply chains will recover.

The spark that ultimately caused the Arab Spring of 2010 were rising food prices in combination with autocratic and even tyrannic regimes.

The combination of high prices, refugees seeking safe haven, and outages can lead to more extreme right governments being elected in Europe (for e.g. Italy). Other countries leaving the EU (Brexit) can cause chaos.

Demographics are typically predictable … but in the framework of a fragile supply chain, certain positions are often held by very few people, when the wrong people leave, it can lead to disruptions along the value chain.

"Antifragility is beyond resilience or robustness. The resilient resists shocks and stays the same; the antifragile gets better."

There are still many tasks, which can be automated around data, business processes, etc. mainly repetitive tasks not on the plant floor, but in operating rooms, and offices. In a survey of plant operators it was exactly these kind of tasks, which were sought to be automated in future to lower support to the operators, free resources and make the people ready for creative problem solving – and who would not argue that this makes a company more resilient and even antifragile.

“The first step to avoid propagating local failures in networked computer systems is to modularize the systems.” Think of these examples:

Sounds counter intuitive but is a measure to get stronger than your competitor. Having tightly integrated systems of controller and programming tools or a large monolithic MES. Initiatives, such as OPAF, universal automation, MTP and others move in this direction.

Having more than one supplier for a certain field device, controller, etc. makes you more resilient against supply problems. We still have reports of delivery times of certain controllers to exceed 50 weeks or so.

Digitalization can make you more resilient as well as antifragile. When processes are digitized, they are codified / written down and can be shared. A digital twin can be sent to be produced elsewhere in the world (as long as the CAD drawings follow a certain standard (see below), plant maintenance staff can be supported by experts in a competence center elsewhere using a digital twin, and maybe even VR / AR.

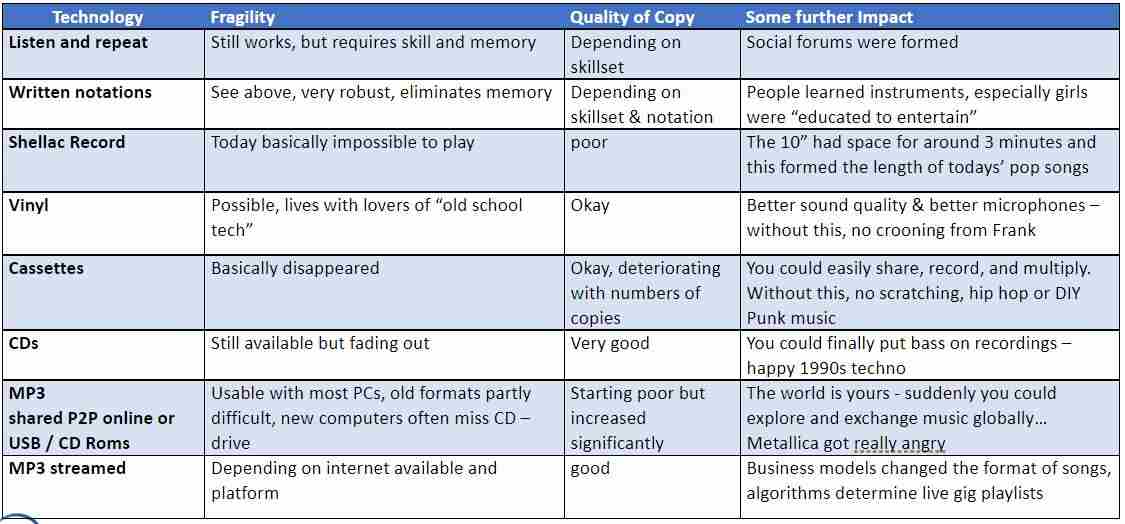

This is a resilience measure. But using standard technology makes it transferable. You can bring outside people in and they are able to work with tools, products, and procedures they already know. When you think about the music example earlier, most technologies worked for decades - and all are standards. There were other technologies in history, which never made it to a global standard and failed, such as Beta or Mini Disc.

It may sound strange, but slight over capacity and a move away from one global world-scale plan can not only increase your resilience, but can make you stronger in crisis, as you can then serve the market with producing 100 percent and sell to others at a high price.

In times of scarce labor force, we should all be extra nice to the people we already have. Leave people some room to breathe. This makes them more creative and also ensures satisfaction. With a low fluctuation rate the lack of engineers is simply a smaller problem.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us