Overview

Owner/operators frequently ask ARC Advisory Group for advice about selecting both technology and technology suppliers. With so many really good technology suppliers out there today and the vast (and seemingly ever-expanding) palette of technologies available to choose from, technology supplier evaluation and selection can be a challenging task. The technology supplier evaluation and selection can represent either an opportunity found or an opportunity lost.

Over the years, ARC has accumulated significant experience in technology supplier selection and developed methods, processes, procedures, and even automated tools that can help technology users make informed, impartial, fact-based decisions.

So clear your minds, put aside your preconceptions, your biases, and your anxieties and let's explore together some of the key issues surrounding technology and supplier selection and review some helpful approaches.

Keywords: Supplier Selection, Technology Selection, Technology Supplier Evaluation, Justification, Definition, ARC Advisory Group.

While supplier selection and technology selection often go hand in hand, it’s important to keep in mind that they are not one and the same. Certainly, whenever capital outlays are involved, choosing the right technology for your business requirements and specific applications is important, but choosing the right supplier to provide that technology and associated support is even more so. Technology is a business tool, but a major supplier is a business partner. The technology user and technology supplier must share a mutual sense of trust and, ideally, a certain degree of commitment to ensuring each other’s business continuity.

This means that the supplier must be willing to invest the time and effort required to gain an accurate understanding of the user’s business and technology requirements, make an honest effort to provide appropriate and cost-effective solutions, and commit to providing long-term support. It also means that the technology user must be willing to help ensure that the supplier receives a fair margin for its products and services so it can continue to invest in its technology, its employees, and the community, while providing a reasonable return for the supplier’s shareholders.

In years past, it was not unusual for manufacturers and other industrial organizations to make technology selection decisions based on relatively esoteric technical points such as the speed of the processor, specific operating system utilized, resolution of the HMI, and/or network bandwidth for a system.

In other cases, technology selections were made on the basis of supplier familiarity and comfort levels. Have we done business with this supplier before? Did they deliver on their promises? How good was the post-sale support? Are they easy to work with? Are their prices competitive? And so on…

While these are all valid points that must be addressed to some degree at some point in the technology/supplier selection process, it's important to remember that the business comes first. Technology supplier decisions, particularly if associated with capital projects, must align with a company's business processes and manufacturing strategy, work to solve specific business issues, and be justifiable from a business perspective.

The first step is to identify the business issue or issues that must be addressed. Is it loss of production due to unreliable equipment or systems? Rapidly increasing maintenance costs? Problems with product quality or consistency? Production bottlenecks? High energy or raw material costs? A shortage of workers with the appropriate skillsets? Regulatory reporting or other compliance issues? While modern technology can help solve all the above business issues -- and many others -- the business issues must be identified in advance, agreed upon internally, and clearly reflected in the selection criteria.

Before creating a general definition for the technology requirements, supplier selection criteria, or specific bid specification, it can be useful to articulate the business issues to potential technology suppliers early in the selection process, since they are often in an excellent position to help map potential technology-based solutions to specific business issues and problems. And while it's only natural for a supplier to be biased toward its own particular approach, garnering a general understanding of the available approaches early on in the process can save owner-operators a lot of time and effort and avoid potential missteps later on. Many technology suppliers have also developed economic justification tools that could help industrial organizations develop a business case for their projects. ARC can also offer our clients assistance in cost justification for automation projects.

While it’s not always easy to develop a business case for a technology investment based on hard ROI, this is almost certainly what a project team will be asked to do before corporate management approves any capital expenditures for new technology.

While some projects, such as applying advanced process control or automating a previously manual operation may be readily justifiable in hard dollars and cents and ROI, others may be more difficult to cost-justify. For example, if your sole justification for replacing an aging control system is that it might fail and bring your whole operation to a halt, it may be hard to convince management to fund the project.

It may be important to look beyond what you are replacing to find value in what you can do with the new capability that would come with the technology. The point is that if the justification involves “soft” benefits, it is important to present these effectively to gain management buy in.

Also, while initial purchase cost is one consideration when building a business case, it’s often far more important to consider overall lifecycle costs for new technology. Some of the lifecycle costs that should be entered into the equation would include: installation costs; integration costs; commissioning costs; validation costs (where appropriate); training costs; operating and maintenance costs, support costs for hardware, software, and firmware; projected repair costs; anticipated service life, and end-of-life migration costs.

Since different suppliers solutions will have different lifecycle costs, these will also have to be reflected in the selection criteria once the project receives the go ahead.

Technology Supplier selection is a team process. The team should have a good understanding of the issues a sense of urgency, balanced judgment, critical technical knowledge, and the respect of peers and management alike. Team member should be chosen not only as decisions makers, but also as the 'doers' that will ultimately follow through on the decisions made.

The team should represent a good balance between technology-focused members and business-focused members. It's also important that all potential stakeholders are represented. For example, for a networked automation system, plant engineering, process engineering, operations, and IT would all have to be represented in some manner.

Another important point to keep in mind is that the more experienced team members will be bringing their personal biases with them to the selection process along with their expertise. These biases will be based on specific technology familiarity and comfort levels, personal relationships, and memories of past projects that went smoothly or turned into nightmares based on the performance of a particular supplier.

On the other hand, with the current shortage of experienced engineers, operators, and technicians, it is becoming increasingly difficult for many organizations to field a selection team with adequate experience with the technology or technologies in question. While this can work to the organization's advantage to a certain degree by minimizing personal biases, it can also make it more challenging to develop (and weight) the appropriate selection criteria and knowledgeably evaluate subsequent supplier responses and proposals.

Defining the requirements for the new technology based on the previously defined business need and justification will often consume a significant amount of time for supplier selection. As explained in more detail in our earlier report, the definition should reflect the company's manufacturing strategy and key performance indicators and any industry-specific requirements. For example, a pharmaceutical company must satisfy US FDA requirements for good manufacturing practices, validation, and electronic signatures. In the heavy process industries where maintenance turnarounds come few and far between, online software upgrade capability is critical to keep the investment current.

The team would have to develop a detailed specification for each class of system or major software package being considered and also consider how the new technology would relate to, impact and, if appropriate, interoperate with existing plant systems and software. ARC strongly recommends a bias toward standards-based technologies whenever possible since this would help ensure both interoperability and long service life.

The most challenging aspect of any supplier selection process is making sure that the selected supplier's solutions are a good fit for the established business needs. As a result, the selection team must have a deep understanding of these needs and agree to their relative importance in the context of the organization's current and future operating environment. This can be a monumental, time-consuming task; and one fraught with confrontation, opinion, and emotion. Once the specific criteria have been selected and the relative weighting of each agreed upon by the entire team, it's important to manage the criteria weighting separately from the supplier ranking. However, the two will have to be combined at the end of the process.

Since different technology areas will involve different selection criteria and these can vary from industry to industry and from plant to plant (as will the relative weighting for common criteria), future ARC Insights will explore this area in greater detail.

Ideally, once a decision has been made, the selection team should be able to readily document how the decision was made, including the selection criteria utilized and the relative weighting given to each criterion.

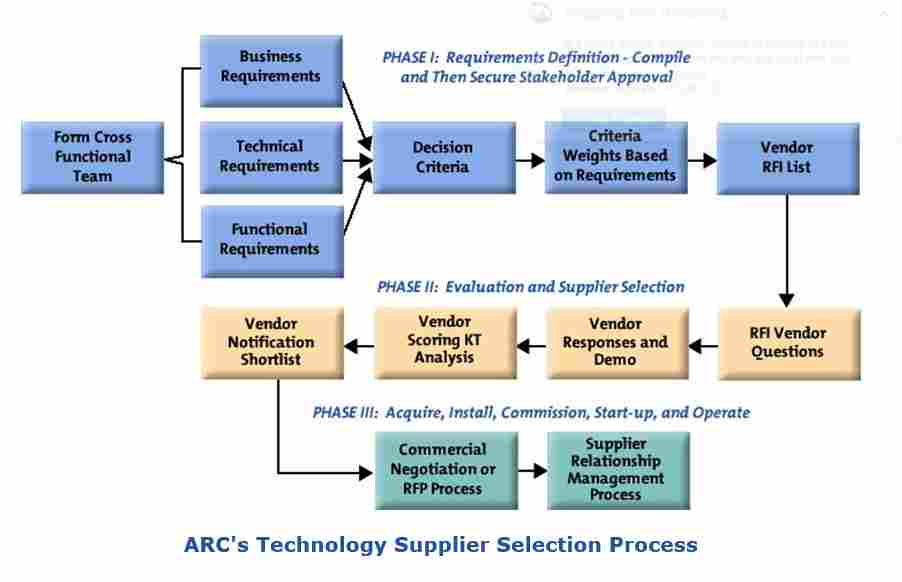

So what's the best way for manufacturers and other industrial organizations to select new technology and technology suppliers? ARC believes that a consistent, structured approach is best. One that aligns selection team members; helps establish consensus on priorities; takes personal biases out of the process to the greatest possible degree; treats all potential suppliers fairly and consistently; makes it easier for team members to collect, organize, and access associated documentation; documents the entire process; and keeps the ultimate business goals in full view.

ARC Advisory Service clients have come to expect ongoing updates and insights into technology trends and specific technologies. At the same time, we’ve provided custom consulting for strategic supplier selections for dozens of end user clients over the years, including some of the world’s largest energy and manufacturing companies.

Building on this, we've recently introduced a formalized program of supplier selection tools and services. We designed these to reduce the time and effort required for industrial organizations – large or small -- to make informed, impartial, fact-based, and well-documented technology supplier evaluations and selections based on real business requirements.

ARC publishes selection guides for most technology products and software applications for energy and manufacturing industries, see a list at Technology Supplier Selection Guides

If you would like to obtain information about how to become a client, please Contact Us