The restructuring of businesses and proliferation of digital data is occurring at an unprecedented rate. Customers on the digital transformation journey must navigate through complex and often siloed data to  achieve their objectives. Established business models have collapsed giving rise to new structures that must coalesce flexibly to improve productivity and operational performance. In this evolving industrial landscape, companies must have proper production insights to plan, operate, and optimize operations; while ensuring that production processes are conducted safely, efficiently, and profitably.

achieve their objectives. Established business models have collapsed giving rise to new structures that must coalesce flexibly to improve productivity and operational performance. In this evolving industrial landscape, companies must have proper production insights to plan, operate, and optimize operations; while ensuring that production processes are conducted safely, efficiently, and profitably.

Many companies rely on a combination of employee wisdom, workers’ confidence in this wisdom, and whatever operational data is available to maintain or improve operational reliability and agility. This produces inconsistent outcomes across the enterprise at best. End users need better resources in today’s challenging environment.

Against this backdrop, senior personnel from Honeywell briefed ARC Advisory Group about the company’s Honeywell Forge Production Intelligence product (part of Honeywell Forge Performance+ for Industrials) that helps combat challenges and efficiently synchronizes production processes.

ARC learned about the product, its differentiators, and how its implementation helps to enhance productivity and operational performance:

The challenges that industries face today are numerous, stemming from the aftershocks of the pandemic, the unending Ukraine war, cultural shifts, and geopolitical posturing. These have resulted in supply chain hindrances and a conflicting regulatory minefield where materials can be harder to find, and products can be harder to deliver. Changes in how companies conduct business with regard to environmental issues have been elevated to an emotional public fervor that changes the balancing act of profit and public relations. Additionally, finding new employees to enter the manufacturing ranks is more challenging as younger people look for more appealing, “socially and environmentally responsible” careers while older experienced workers continue to retire taking with them valuable expertise that employers have relied upon for competitive advantage.

These overarching challenges trickle down throughout an organization requiring manufacturers to respond quickly to the dynamic landscape. One way companies can address environmental issues is with more efficient processes; using less energy and producing less waste. Another operational challenge is how to efficiently use human resources; having the expertise to identify and focus on the most important problems while helping to resolve those problems quickly, avoiding quality issues, unsafe conditions, and downtime.

In response, ARC sees the adoption of operational analytics and the successful transition of it into a scalable core competency as following a common arc for industrial manufacturers. Companies begin in a reactive state, focused on operational reliability and with limited, ad hoc, and offline, or manual analysis. They then move to integrate analytics to improve operations and better implement a digital-first mindset. Finally, they incorporate customer feedback into analytics so that the insights generated enable uniquely differentiated responses, allowing for quicker production response to customer needs.

Without the support of modern analytics, operations teams must solve problems based on recency of information and established operational practices, regardless of their merit. This means that organizations make most decisions by combining experiential wisdom, workers’ confidence in said wisdom, and whatever operational data is available with an aim to maintain or improve operational  reliability. Unfortunately, this inevitably leads to inconsistent outcomes.

reliability. Unfortunately, this inevitably leads to inconsistent outcomes.

This approach is a natural effort to make decisions based on the best information the organization has access to and the prevailing knowledge of experts. However, it leads to reactive decisions based on poorly informed observations and perceptions of risk, and so it cements a working culture where incentive to change is lacking. Often, when analytics are later applied, this way of problem solving is proven to be error ridden.

Hampering efforts to address these challenges in the digital era are siloed and disparate data. To react and even thrive in the current market reality, end users must seamlessly integrate an overwhelming load of data from diverse sources to support business processes and provide real-time information. IT/OT data convergence must accelerate to combine the best of both worlds. Data is touted to be the new oil, but it certainly needs refining due to:

Honeywell Forge Production Intelligence endeavors to combat these challenges, improve production performance, and reduce operational costs. After explaining the salient features of the product, Honeywell substantiated it with successful case studies.

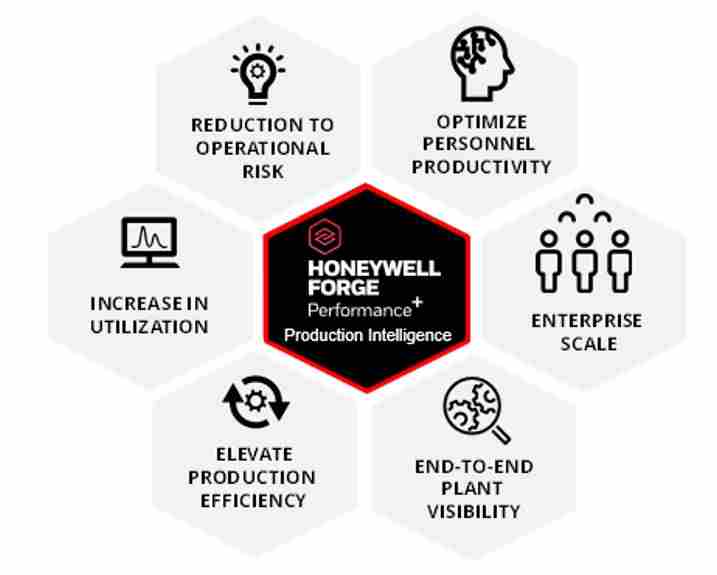

The Honeywell Forge Production Intelligence is a cloud-based product that is designed to collect cross-functional, multi-dimensional data from process, control, assets, alarms, and operations. Unification of this disparate data provides the needed insight to help maximize and improve operational performance. It contextualizes data across multiple systems to create contextual data for insight and analytics driven decisions. This product also provides real-time operational monitoring to unify OT and IT data and deliver actionable insights at the enterprise level down to the individual process unit for production operations. Through its integrated perspectives, guided diagnosis, and insight to bad actors, industrial users can spend less time sorting through operational data and more time optimizing performance.

It further provides a unified system of record for the organization by integrating siloed OT data and applications to streamline operations and derive additional business value by extracting base relationships, contextualizing, synthesizing relationships, and recommendations to optimize production operations.

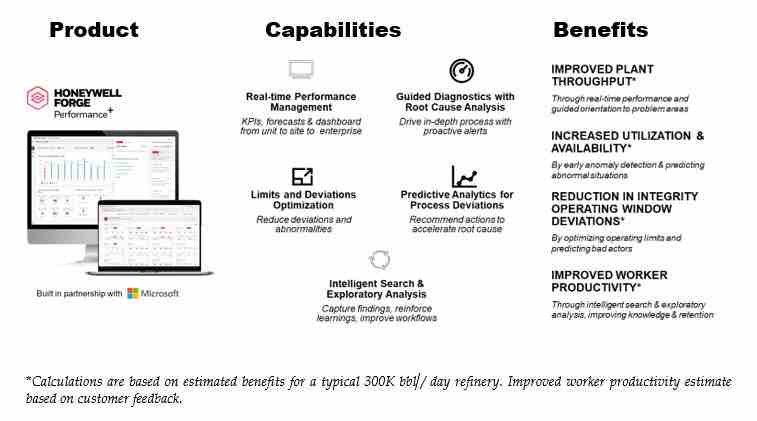

Figure 1.0 Production Intelligence Overview

For end users in Industrials, we provide an analytics & insights solution that provides integrated perspectives, guided diagnoses, insight to bad actors, optimized production, and sustained productivity for maximum performance and long-term growth.

The five foundational capabilities of the solution are:

Honeywell explained (via use cases) how the product helps optimize the operating envelope; predicts quality and abnormal situations; provides automated data validation and deployment; and achieves the expected outcome. Quoting Honeywell: “It is a tool that enables not only to plan for today, but provide better insights for tomorrow.”

The company offers three go-to-market modules that allow organizations to gradually scale their application according to their needs:

Core: Analytical data that pinpoints what happened. This module provides real-time monitoring capabilities through standardized connectors, persona-driven dashboards, and operational insights.

Diagnose: Process tools to find out why it happened. Builds on the Core module’s capabilities and provides robust process visualization and industry-driven analytics to understand likely causes and deviation resolution.

Predict: AI/ML analysis of what’s likely to happen. Expands on the capabilities of the previous models and helps to identify, address, and prevent future production issues through AI insights.

Predictive analytics presents several different benefits to end users. One application might be optimizing a process’ operating envelope given a specific set of parameters that could change based on the market conditions. The ability to predict abnormal situations and avoid them has always been a high priority. Insight that allows operations to predict deviations from a product quality target would allow manufacturers to avoid wasted energy, labor, and materials. Maintenance might benefit from the ability to predict deviations in measurements as well.

Case studies authenticate a solution’s efficacy and the tangible benefits to the customer. Also, other customers can gain insights and evaluate if the solution could help streamline their processes too.

Honeywell has implemented Production Intelligence and is also working with early adopters. Select initial learnings and insights are highlighted in the following case studies.

Customer’s requirement: A software platform that provides a coherent view of OT Data opposed to the existing disconnected data systems. The objective was to improve situational awareness and drive root cause analysis of problems of the engineers.

Solution: Intelligent Search enabled the customer’s engineers to identify objects of interest with details for OT system analysis. Additionally, Data Lineage identified system interdependencies and relationships across underlying OT application data for troubleshooting and maintenance activities.

Impact: The solution enabled the users to see data relationship details. The reduction of manual errors allowed for faster, safer, and consistent operations; and steady, consistent improvements to end users. Human error is eliminated from both troubleshooting and maintenance efforts, facilitating faster, safer, consistent operations, and improved knowledge capture. Streamlining operations reduces unplanned shutdowns, stalls, etc.

Customer’s requirement: To compile complex asset data to analyze and contextualize from a reliability perspective. The customer's existing asset management process was structured through an enterprise asset management (EAM) hierarchy, with each individual asset having a unique name in the system. The customer relied on this hierarchy for all maintenance work orders and strategies, which created a siloed and spread-out system of record. They needed a way to automatically link process data to their physical assets.

Solution: Scoping a plan with the customer to add additional metadata to the source data to map the EAM assets into the common asset model (CAM), covering the mapping for all data that is generated by the process management including the process control network data.

Impact: This solution will allow the customer to streamline mapping of asset data and reduce shutdowns. EAM data from separately-functioning operations can be contextualized and mapped to a singular source, including data such as alarms per day, loop performance data, basic process instrument data, logs, loss accounting data, etc. When all asset data is mapped to a common asset model, production efficiency increases.

Customer requirement: The customer sought to replace about 7 OT applications; of which Honeywell was selected for 3 (Operator Logbook, Inspection Rounds, & Production Intelligence), and needed visibility into key performance indicators (KPIs) prior to the startup of new operations.

Solution: Honeywell’s prepackaged KPIs, domain knowledge, and expertise in a new full SaaS-based solution, and a flexible implementation model provided a viable solution for the customer. Also, working with a local integration team made the implementation process smooth.

Impact: The Honeywell solution provides a single version of truth and transparency, pre-packaged refinery KPI’s, widgets and persona-based dashboards accelerated the time to value for the customer. Accurate, prompt, contextualized information with visibility into both plant operations and alignment with business processes. Benchmarking of actual production vs. plan and achievement of performance targets.

The briefing by Honeywell made it clear that organizations on the digital transformation journey must deploy analytics to gain operational insights and optimize performance. Integrated data is critical for the success of every organization, and Honeywell Forge Performance+ for Industrials Production Intelligence helps to seamlessly integrate data to take informed decisions that improve production processes. The product provides an end-to-end visibility of operations, helps to zero in on problem areas, and recommend corrective actions. The multiple benefits of deploying the solutions were validated by successful case studies. Such scalable and replicable solutions are invaluable for companies grappling in a turbulent business environment.

Through discussions with the end user community, ARC concludes that solutions that contextualize data by removing boundaries to create actionable information are sorely needed. Industry continues to grapple with the loss of expertise through higher rates of attrition and the challenges of onboarding new talent. Capturing and institutionalizing the knowledge of how different buckets of data relate within a single interface and making it available to the right employees 24/7/365 will be crucial to maintain competitiveness in the near future. The pandemic, subsequent supply chain disruption, and the Ukrainian war highlight the need for operational agility. The quicker actionable information is available, the faster the business can respond. Businesses want to respond faster than their competition.

Industrial organizations need to rethink deeply entrenched approaches to how they organize their work cultures and operate their businesses. This begins with leadership, which needs to evolve beyond transactional decision-making so traditionally prevalent in industrial markets. Those that achieve success will instill a digital-first industrial work culture, accounting for (not penalizing) a workforce with different levels of digital comfort.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Honeywell Forge Performance+ for Industrials Production Intelligence, Production Processes, Digital Transformation, Operational Performance, IT/OT Convergence, Predictive Analytics, ARC Advisory Group.