Developments in the warehouse are even more interesting; autonomous mobile robots for the warehouse provide good ROI and a flexible, scalable form of automation. Meanwhile, robotic picking technologies are maturing.

But how ready are these technologies for actual usage? ARC believes that:

Smart machines rely on advances in computing power to operate. Enabling technologies include artificial intelligence and machine learning; a variety of lower cost, but more powerful sensors; vision recognition; 5G networks; control systems; and intelligent integration of machines to enterprise applications or routing solutions.

Other new and interesting technologies being developed for logistics purposes include blimps; high-speed, “hyperloop” transportation systems; and electric trucks, but since this report focuses on smart machines, we do not discuss those here.

The ongoing, rapid growth of e-commerce continues to place exceptional burdens on existing fulfillment networks. Not surprisingly, robotics-based warehouse technologies that support high volumes of small, multi-line orders are receiving the greatest interest from practitioners as they realign their capabilities with the changing demand profile. Further, in comparison to bolted down material handling solutions like conveyors and high speed sortation, robots are far more flexible. If demand grows, you add more robots. If your warehouse is poorly located, you can often just march or load your robots onto a truck and move them to the better location.

These solutions integrate more easily into a warehouse management system (WMS) – the core system that oversees warehouse operations - than other forms of automation. Advanced WMS solutions control people’s work using a directed work task queue. An AMR is no different than a typical user; you can control it through a work queue, just like you would a human. This task queue knows source and destination locations, and work gets routed to users (human or robots) based on permissions, priority, and the proximity of the work to be performed.

Even though these solutions are not yet widely deployed (except at Amazon), they cannot be considered an immature or emerging technology. Amazon has proven they can be used at scale with a solid ROI.

The existing solutions do not pick goods from shelves. They either bring the shelves to people, or people pick into containers on the robots and the robots then deliver the products to a pack station or the loading dock. The ROI comes from allowing workers to be more productive as robots eliminate human travel through the warehouse.

New developments, however, could lead to a robotic revolution in logistics. In factories and packaging lines, robots have been performing picking operations for decades. In these settings, an engineer designs tooling that picks the same item that is presented to the robot in exactly the same way for millions of cycles. But in an unstructured environment like a warehouse, there is incomplete information about the item and a lot of variation. In other words, a wider range of items are presented to the robot in different orientations. So, the robot needs to be smart enough to pick up different shapes, detect if the grasp was good, know where to place the item, and determine if the item was placed successfully.

Flexible grasping has been the “holy grail” in robotics research for years, but is a very difficult problem, particularly for warehouses. This is because warehouses can have large numbers of SKUs that vary in many ways – size, weight, shape, stiffness, etc. Solving this problem requires deep expertise across machine learning, vision, algorithm optimization, and hardware design.

Currently, picking arms are not being used with mobile robots. But the combination of the two technologies will be revolutionary. Many pundits have forecast that virtually all truckers will eventually lose their jobs to autonomous driving technology. But since the technologies that will power fully autonomous vehicles are far from mature, it’s far more likely that, within the next fifteen years at least, AMRs equipped with picking arms will eliminate far more jobs than autonomous vehicles.

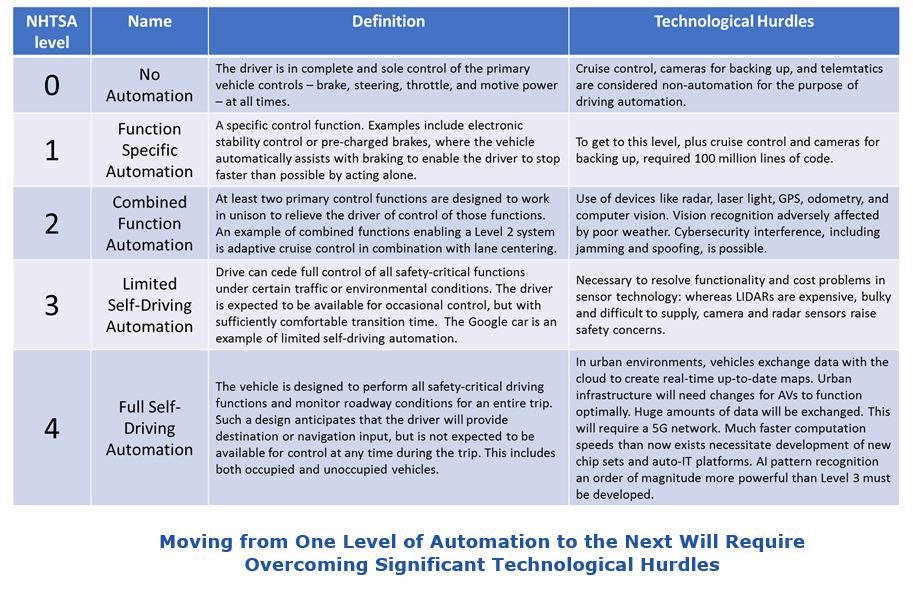

We’ve been on the journey toward autonomous vehicles longer than many realize. Yet, despite the billions of dollars invested in multiple autonomous vehicle (AV) technologies, the road to fully autonomous vehicles operating in an urban environment involves surmounting almost unimaginable technological hurdles. Additionally, legal, infrastructure, and economic hurdles still need to be overcome.

While the different levels of automation suggest an incremental increase in functionality to move from one level to the next, the differences will require degrees of magnitude increases in capabilities. Truly autonomous trucks will need exponentially greater sensing, decision-making, and computer speed than trucks operating just one level down in the automation hierarchy.

And the more vehicles on the road, the more sophisticated the autonomous infrastructure must become. Vehicles will communicate with vehicles in the lanes next to them and as they approach an intersection. Meanwhile, traffic lights and road sensors will also be communicating with the AV cloud.

However, while it may take decades to get to fully autonomous vehicles that can legally operate in cities, the impact on logistics can occur incrementally as trucks move from one level of automation to the next. The way station on the road to full autonomy will include better advanced driver assistance systems and semi-autonomous vehicles.

Interesting pilots are being conducted with semi-autonomous truck convoys in which several trucks connected via automated systems form a single “road train.” When the first truck brakes, every truck in the convoy brakes the same amount. When it speeds up, they all speed up equally.

While these truck trains save money on fuel from slipstreaming, they still require drivers in all trucks to be ready to take over if problems occur. Relatively few carriers or shippers would need to send a platoon of trucks to a common destination, but the technology could get interesting when trucks headed in the same direction can find each other and invite each other to join the convoy. This technology does not yet exist.

Another problem with semi-autonomous trucks involves the idea that the AV system will be responsible for driving for several hours and then when a problem arises, the driver will be alert and ready to jump in to avoid a collision. It is likely that all too often in these scenarios, drivers will be sleeping, using smartphones, or otherwise occupied, and thus unable to jump in to take control in the required response time.

Almost four years ago, Jeff Bezos - the CEO of Amazon - went on the popular US TV news show, 60 Minutes, and unveiled his vision of having drones deliver packages right to customers’ doorsteps. Ideally, this could occur within 30 minutes of the order.

The idea that drones could be used for deliveries is not farfetched, but that drones could deliver goods directly to a customer’s door is still likely to be many years away.

So, where do things stand today?

In August, the drone technology company, Flytrex, in partnership with AHA, Iceland’s largest online marketplace, announced the official launch of the world’s first operational on-demand urban drone delivery service. The CEO of Flytrex, Yariv Bash stressed that “This is a working system, not a one-off wonder.”

Following regulatory approval from the Icelandic Transport Authority (Icetra), Flytrex, and AHA received approval to implement their autonomous drone system to deliver food and consumer products from shops and restaurants on one side of Reykjavík to a designated point across the city. The new drone logistics system allows direct delivery between two parts of the city separated by a large bay. The drone can do in four minutes what it takes a car 25 minutes to do in heavy traffic. The drone lands in an empty field near the designated neighborhood where it is met by a courier. The courier then walks, if the customer’s home is close enough, or drives a short way, to make the final delivery to the doorstep.

In the US, drones are required to have an operator in the line of sight of the drone. This delivery service is based on deliveries outside the line of sight. This was accomplished through a stringent regulatory process where the drones have a designated flight path that is closed to airplanes and other drones. The drone’s operator maintains contact with the control tower, if a plane is drifting into the drone’s flight path, the operator is notified and he will prevent any other take offs.

As a next stage, Flytrex will deliver to a customer’s backyard. The delivery will be part of the same flight path to the neighborhood that has been approved by the Icetra, but with new map coordinates added that specify the location of the backyard. The drone will hover 50 to 60 feet in air, and then lower the product to the end consumer. Logistics are coordinated based on a smartphone. The consumer will have visuals showing the estimated time of arrival and the drone’s current location. When the drone arrives at the destination, the customer is notified and the drone hovers above the destination until the customer acknowledges that they are ready to accept the delivery. When the customer presses the “accept delivery” button, the goods are lowered to the ground.

It should be noted that Flytrex is not a drone manufacturer. In fact, it is drone-agnostic. The company has produced a cloud-based drone management system. The entire system includes functionality that allows the operator to communicate with the drone, smartphone enablement for estimated times of arrival and delivery activation, integration into the shipper’s logistics systems, and communication with the aviation regulatory agency.

When ARC asked about Jeff Bezos’ vision of delivering right to a customer’s doorstep, Mr. Bash responded “these devices are too dangerous to be near untrained humans.”

The widespread use of drones for doorstep deliveries is years away from being practical. Even deliveries to courier staging areas will require regulatory clearance of flight paths. Being able to scale up to accommodate the necessary number of flight paths over a large urban area will be extremely challenging.

But drones can play other roles in logistics that comply with aviation regulations. PINC offers a solution called PINC Air. This is an aerial sensor platform that operates both outdoors and indoors to inventory hard-to-reach assets using an array of sensors, including GPS, RFID, OCR, and barcode readers. PINC Air is basically a supply chain drone that has multiple use cases. Each of these use cases allows a company to perform tasks via the drone, rather than in the more timely and costly manner using people. The use cases include:

Drones are also ideal for assessing, inspecting, and photographing land and buildings. It is becoming standard practice to include drone photographs in real estate sales listings. Recent software developments can create 3D models of buildings, equipment, or whole facilities using algorithms that extract a wireframe model from a large collection of overlapping photos taken by a drone.

The downside of this is that competitors can also use drones to get insights about a competitor’s supply chain and/or facilities by examining their plants and warehouses. Services are available to counteract this kind of unwanted surveillance. For example, a company called DroneShield was hired last year to provide drone-detection services near the Boston Marathon. The company’s “counter-drones” came equipped with special net guns to capture any unmanned aerial vehicles identified to be violating a ban along the race course.

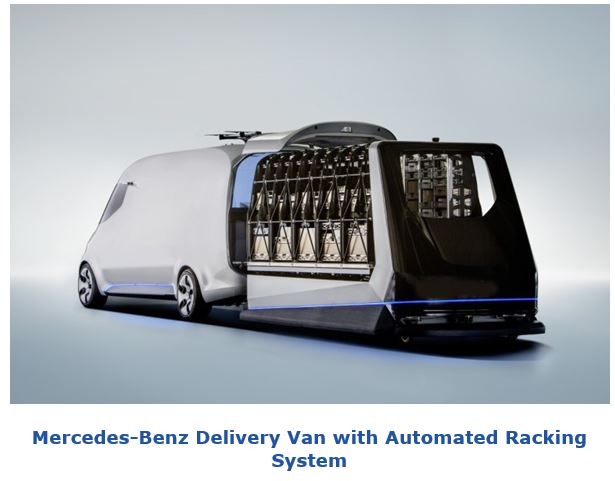

In September of last year, Mercedes-Benz Vans announced an equity investment in startup drone company, Matternet, and that the company planned to invest €500 million over the next five years to design electric, networked, potentially self-driving vans from which drones can be launched to obtain or assist in delivering packages. Whether or not an integrated van/drone system to support doorstep deliveries is practical at this time, the new van being developed specifically for last mile deliveries has several very nice features, including automated systems to assist the driver. For example:

Even though the drone part of this is impractical; this is a good idea nonetheless. The idea of a car maker as a provider of a holistic delivery system that combines the vehicle, material handling hardware and special racking, and enterprise software is very interesting. That, not drones, is what makes this step forward in support of last mile logistics.

Many companies have become good at managing risks. But when it comes to emerging technologies with the potential to disrupt existing business models, it is not about managing risks, it is about managing uncertainties. Risk has known outcomes with attached probabilities. Uncertainties have unknown outcomes and thus there can be no knowledge of the probabilities associated with a particular outcome. This knowledge must be developed through well-targeted pilot programs.

For large carriers and 3PLs, even if an ROI-based business case can’t be built at this time (such as for autonomous long-distance trucks or drones for doorstep e-commerce deliveries), teams need to be assembled to pilot and carefully evaluate these technologies. This is consistent with ARC Advisory Group’s often-articulated position that those companies that wish to remain competitive and viable in the years to come, cannot be too conservative now when it comes to evaluating the potential business benefits (reduced costs, improved worker productivity and safety, etc.) offered by the latest smart, connected technologies, solutions, and approaches. That’s because to do so would open the much greater risk of getting left behind.

Many driver-assist features stemming from development of autonomous trucks (brake assist, blind spot warning, adaptive cruise control, etc.) already help increase road safety. And autonomous mobile robots already have proven ROI in warehouses. Any distribution center or shipper active in e-commerce or other logistics operations should examine these types of solution sets.

If you would like to buy this report or obtain information about how to become a client, please Contact Us