Summary

Compressor Controls Corporation (CCC) recently briefed ARC Advisory Group on its new Total Train Solutions offerings. These solutions leverage CCC's sibling business SETPOINT Vibration and partnership with OSIsoft to deliver a more holistic compressor train solution for its customers. CCC believes this approach will significantly reduce the time required to troubleshoot machinery issues and reduce the required IT infrastructure for online analysis.

Key findings include:

Compressor Controls Leverages Its Portfolio

According to the company, CCC was founded in 1974 as the inventor of the world's first digital anti-surge control system. The company has served the process control industry for more than 40 years. More than 10,000 turbomachinery trains worldwide are powered by CCC control solutions. CCC is widely recognized for its Series 3 controllers for turbomachinery. According to ARC research, the company is a leading supplier of turbomachinery control solutions globally, with in-depth application knowledge.

By adding SETPOINT's machinery protection and condition monitoring products and services to its portfolio, CCC can now address vibration, temperature, and pressure monitoring for turbomachinery all within its own product suite. This online condition monitoring software solution connects directly to the SETPOINT machinery protection system without the need for any additional hardware. It provides visualization tools such as time-base, orbit, spectrum, bode, polar, shaft centerline, multi-variable trend, and other plot types specific to rotating and reciprocating machinery. These allow online condition monitoring analysis and machinery diagnostics.

Partnering to Complete the Solution

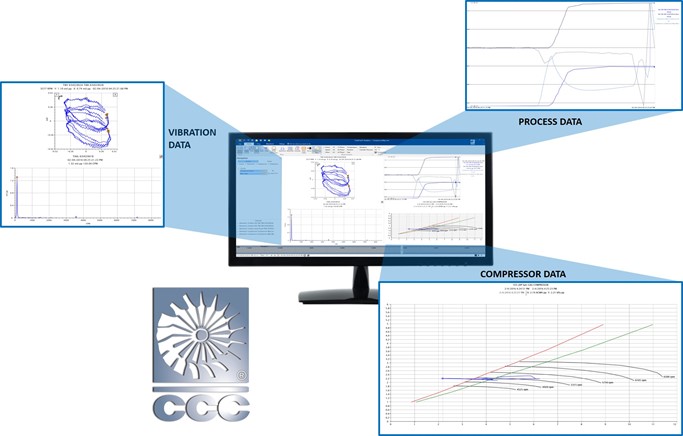

Total Train Analytics

Total Train Analytics, a new CCC software solution, is designed to bring all the different pieces together to simplify the customer's machinery analysis workflow. It brings process data, compressor data, and vibration data together in a common HMI, fed by a common data repository (the PI System). Regardless of the installed vibration monitoring equipment, hardware gateways allow end users access to these signals and subsequent streaming of the full vibration signal (including waveforms) into PI. The key to this integration is the Total Train Analytics visualization software. It combines the compressor map capabilities of CCC's TrainView software with all of the vibration tools in SETPOINT's condition monitoring software and all of the high-resolution trends of all plant process data in the PI System. This new application pulls together the machine data, process data, and compressor control data into one interface, allowing the user to quickly identify correlations.

CCC Total Train Analytics

In the past, users would print historical trends from different software packages, overlay them, and "hold them to the light" to find correlations. By using a single interface, the scaling and overlays can be made immediately, on demand. According to the company, users can easily collaborate with other experts, locally or remotely, to help quickly solve problems using standard PI System tools as well as the Total Train Analytics display software. Technologies such as Citrix and Microsoft Remote Desktop allow use of these tools even on mobile devices.

According to CCC, the use of the PI System also reduces the number of additional PC's required to pull the data together, hence reducing the amount of expensive IT support required to maintain the system.

Conclusion

Compressor Controls Corporation's focus on the totality of the compressor train appears to be a winning proposition for end users.

ARC sees this holistic approach to turbomachinery as consistent with market trends. Finding a trusted partner to supplement on site expertise is critical as the experienced workforce continues to contract. Collecting disparate pieces of data into one unified software solution allows personnel to quickly compare data trends, enabling them to more quickly identify and effectively remedy problems. This should translate into reduced turbomachinery downtime higher overall equipment effectiveness (OEE) and add to the bottom line.

ARC Advisory Group clients can view the complete report at ARC Client Portal on www.ARCweb.com or Box.com

If you would like to buy this report or obtain information about how to become a client, please Request ARC Info

Keywords: Compressor Controls, Turbomachinery, CCC, SETPOINT, OSIsoft, Root Cause Analysis (RCA), Vibration Monitoring, Condition Monitoring, Equipment Health Management, ARC Advisory Group.