ABB Electrification Service (ELSE), the service division of ABB Electrification (EL), has invested $1 million to create the Digital Solutions & Training Centre in Singapore to cater to key markets in the Asia Pacific region. At the official opening event, Stuart Thompson, Global President, Electrification Service, and Andrew Stepien, Senior Vice President of Electrification Services, Asia Region, talked with ARC about the purpose and capabilities of the new facility, the evolving service needs of ABB electrical equipment users, and the opportunities that come with developing deeper, technology-enabled relationships with customers.

Complementing other similar service facilities we have around the world – in Italy, in the US, in Dubai (opening later this year), it will serve the needs of our customers right across Asia Pacific, aside from China and India, which have their own dedicated, in-country facilities. The Centre will be fully operational by Q4 this year, providing training for 100 to 150 ABB staff members, partners, and customers across the region, rising to 300 participants annually. In addition, working together with similar facilities elsewhere in the world will give us the ability to support customers 24/7 wherever they are located around the globe.

We did consider other places in the region to site the Centre, and these were actually lower cost than Singapore. But the location here is ideal in terms of the ease of getting in and out from other parts of Asia Pacific, and across aspects such as data security, internet infrastructure, and available skills levels. We also have many of our most demanding customers here. So overall, it was the logical choice to make the investment in Singapore.

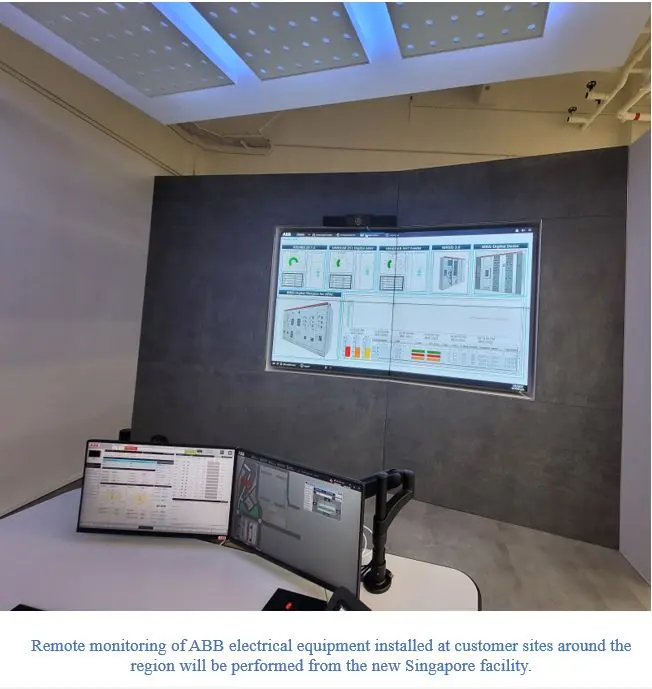

When we sell product to a customer there is a certain amount of equipment training expected and required. Previously, we would typically fly people to Europe for training, but now we can conduct that right here. Our own technical staff from around the region can also now travel to Singapore for their competency development, rather than to places much further away, which means equipment training and familiarization is more easily available. Then there’s the Digital Solutions side of the facility, whereby the service agreements that we sell will specify a connection back here such that, where customers allow, we can perform remote monitoring of equipment – from basic troubleshooting to online, full-time condition monitoring.

In the utility sector, with concerns around energy security in Europe after the start of the Ukraine conflict, there has been a lot more focus on retrofits and upgrades as operators look to get assets more stable and self-contained. In the US too, with the Inflation Reduction Act, we see demand for equipment to be updated and modernized. Sustainability is becoming much more important for customers as they look to do things like reduce carbon footprint by improving the maintenance of their assets. What we're also seeing in the market is this continually ageing workforce in certain parts of the world and a lack of skills and capabilities in others, which is making it harder to run and operate facilities effectively.

For us at ELSE, all this translates to four key priorities we look at delivering to electrical equipment customers: Availability, Reliability, Predictability, Sustainability. And we do that through the provision of three types of service offerings: Care – for the early phase of startup, involving installation, commissioning, maintenance, training, and spare parts provision, Modernization – for when a system has been in for a number of years and customers want to upgrade to make them better, smarter, and often to add features necessitated by new standards; and Advisory – where ABB becomes a trusted advisor to help companies to e.g. meet reliability and sustainability targets and prioritize investments.

As a division, we are really pushing on the digital button right now, because you can’t get to the necessary levels of availability, reliability and predictability without the enhanced monitoring and diagnostics afforded by digital technology. We have moved a lot from doing first-level type services ourselves to enabling the customers to do these by, for example, scanning a code on the ABB equipment, which brings up the specs of the product and guides the customer through basic levels of fault finding. For next-level support, instead of flying people out to a site, using augmented reality technology facilitates remote diagnostics and quickens the time to service resolution.

We have contracts in place with global customers, where we monitor their assets remotely and provide insight into the health of equipment and provide maintenance recommendations to reduce the chance of equipment failure. We do, however, have a larger percentage of customers that want the data to stay on premise, which means we go to the site and do the analysis there. Interestingly, right now, it’s sectors like food & beverage and buildings and infrastructure that are more open to ABB cloud hosted data than the more critical industries like oil & gas and power.

While ABB services and the capability of the teams have always been appreciated by customers, the perception was really one of spare parts and warranty support for the ABB product businesses. The company realized there was a lot of untapped value creation, which was why we were pulled out as a separate division from ABB Electrification earlier this year. With the establishment of ELSE, customers are starting to see the investment in different areas and us talking about different things like sustainability and as-a-service models. About 70 percent of our business is directly to the end user, it's not through a channel, which means we’re talking directly to large industrials and utilities. Going forward, building those relationships through Advisory, where we’re most actively recruiting staff, and developing strong collaborations and new styles of interaction with customers will generate recurring revenues, which will be key to future growth.