ARC Advisory Group’s 21st India Forum titled Driving Sustainability, Energy Transition, and Performance through Digitalization on July 12th and 13th, 2023 saw a turnout of over 300+ delegates. ABB participated as a Global Sponsor at the Forum and in the session on Digital Transformation and Sustainability Initiatives (Part 2) , Krishna Kumar, Sales Director for AMEA region, Digital Business, ABB Process Industries spoke about reducing environmental impact with ABB’s integrated and sustainable digital solutions across a swathe of industries. His presentation was substantiated with successful case studies that can be replicated globally. This blog captures the essence of his presentation; it can be viewed in entirety here.

Sustainability is hitting the headlines and it features on everyone’s agenda. Governments have sustainability goals that are stipulated by the United Nations; organizations are hiring sustainability officers; and conversations revolve around blue hydrogen/carbon emissions and so on. The entire sustainability initiative is a convergence to combat climate change and save the environment/planet. A survey by CDP (carbon disclosure project) with about 4,000 customers reveals that only a small number have a credible plan and the jigsaw puzzle of sustainability remains largely unsolved. There are multiple levers of the sustainability puzzle that organizations can look at, such as CapEx investments to change the process and reduce carbon emissions, deploying technologies like carbon capture and storage etc. “But there’s one big lever that already exists, which can be geared toward sustainability and that is digitalization,” said Krishna Kumar. Digitalization is a key pillar to enable sustainability goals.

There are various levers that an organization uses when it drives sustainability goals. Krishna Kumar referred to this as the “carrot and stick approach.” Carrots include energy efficiency that results in profitability, carbon trading ecosystem, and access to capital for various sustainability initiatives. Sticks include government rules and regulations (emission norms, water effluents, energy violations, etc.) that attract fines if flouted.

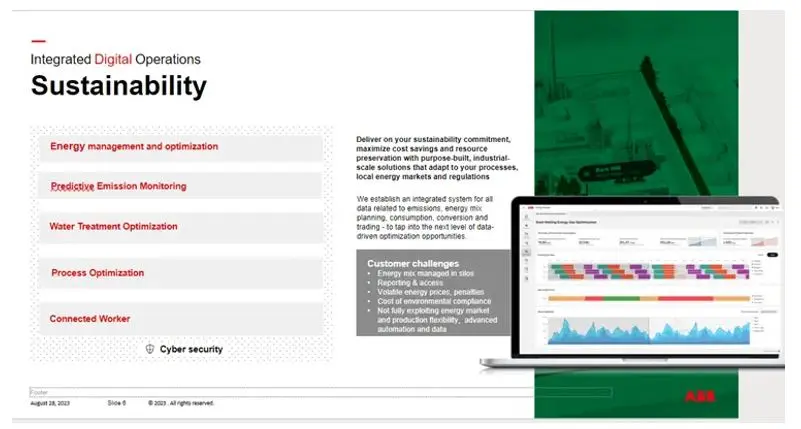

ABB looks at digital solutions from five value pillars all with embedded cybersecurity best practices: Operational Excellence; Sustainability; Asset Performance; Process Performance; and the Connected Workforce.

Krishna Kumar said that under the umbrella of sustainability there are five pillars and under each one he cited use cases.

Energy Management and Optimization: There are three modules through which ABB resolves the energy management problem: monitoring and reporting; load planning and forecasting; and holistic optimization of energy demand and supply. In this context, Krishna Kumar spoke about ABB Ability Energy Management System for Industry and how it addresses these areas.

Use Cases: Pulp and paper customer who had major shutdowns occurring due to certain energy peaks that they were hitting as part of their operations. ABB did a detailed energy audit and implemented an energy monitoring solution that led to 9 percent saving in overall energy cost.

ABB helped a metals customer to optimize and schedule energy usage. Multiple trips were occurring as the customer wasn’t using the right amount of energy at the right time; so planning, forecasting and scheduling was essential.

A global cement plant in multiple locations deployed ABB’s solutions to optimize energy consumption from various resources (captive power, grid, and renewable resources).

Process Optimization: ABB has been doing APC (Advanced Process Control) for over 30 years. The key now is optimization not just from the throughput point of view, but what is the optimal energy required to maintain that throughput.

Use Case: Cement mill in Brazil. APC increased process stability and improved the bottom line. The mill’s energy consumption reduced by 1.15kWh/t. For a typical cement plant this would equate to roughly a reduction of 500 tons of CO2 per year. This is applicable across all industries.

PEMS (Predictive Emissions Monitoring Systems): CEMS (Continuous Emissions Monitoring Systems) is common across industries, but often this could be an expensive and unreliable solution due to the hardware involved. Hence, PEMS is an alternative that is affordable, reliable and compliant with US-EPA and EU frameworks and has been implemented in the Middle East too.

Water Treatment Optimization Use Case: ABB worked with a pulp and paper mill customer to reduce energy consumption by 10-20 percent and reduction of chemical dosing expenditure. This had a direct impact on the bottom line. Additionally, there was tighter control over water quality and chemical dosing.

Integrated Digital Operations: ABB’s integrated digital operations considers issues holistically. For this, existing tools can be augmented with new technologies to tackle problem areas. ABB helps to meet sustainability targets via multiple pathways and provides an integrated approach. This provides a single source of truth and enables conversations between different teams and departments. Krishna Kumar spoke about how this integrated approach helped a cement plant reduce operating costs by 3-5 percent across multiple plants.