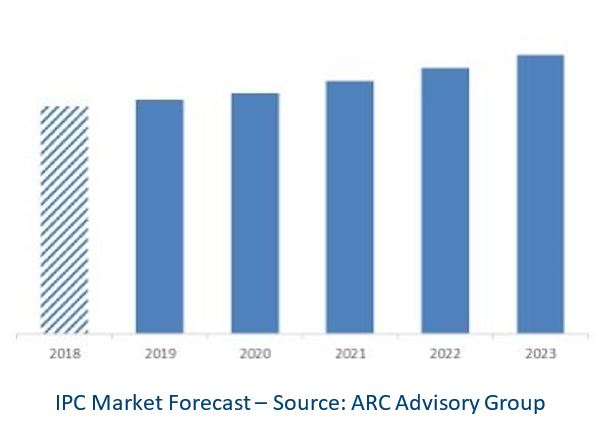

The IPCs in manufacturing market grew at a good pace in 2017 and 2018. However, the growth spurt is stuttering since Q2 2019, and the prognosis for the next five years looks not as positive as it did a year ago.

Different political and economic issues are having a strong negative impact on most industries. The automotive industry, the most important market for IPCs in the manufacturing space, is being hit particularly

For 20 years, the Chinese car market was only moving in one direction – uphill, making it the global growth engine of the auto industry. The slowing economy, stricter emission rules and the current US-American policy have led to a dramatic decrease of China's car market growth. As a result, investments into the production automation have been reduced worldwide, and factories/ production facilities will be closed or transferred, not just in Europe. After a decade of continuous economic expansion, driven mainly by China, this slowdown will expose just how much today’s global economy is governed by economic interdependencies.

On the other hand, global industrial trends, like digitization, and increased automation are still pushing demand. The different concepts of digitization offer the promise of increased production flexibility. The increasing need for data from the plant floor is also driving demand for IPCs for data collection, analytics, and data transfer.

There are also some other technical trends and developments that drive the IPC market, or act as a buffer for the economic and political downward trend. One is triggered by “Data Collecting Mania” mainly driven by new artificial intelligence (AI) applications. The integration of AI into industrial applications increases the demand for computing solutions that can cope with the complexity of the tasks. In addition to the CPU, processors specialized in AI algorithms and large amounts of data are gaining momentum.

Industrial applications in the field of artificial intelligence require much higher computing power than traditional 'standard' applications. Increasingly, these applications are moved closer to the sensors, or directly to the machine, and this is known as edge computing. The necessary data volumes with their high bandwidth can and should not be transported over a poorly controllable public network. Edge computing requires data handling and transfer in compliance with the applicable real-time requirements of the industrial environment, while making cyber security a top priority. As a result, AI at the machine requires reliable, powerful and robust hardware, thus driving the industrial PC market.

ARC has identified other interesting trends, insights and aspects for the IPC market and will continue to publish about them in the near future. For more information about this research, or other topics, please feel free to contact myself or your ARC Client Manager or visit https://www.arcweb.com/market-studies/industrial-pcs.