Siemens participated as a Global Sponsor at ARC Advisory Group’s 21st India Forum titled Driving Sustainability, Energy Transition, and Performance through Digitalization on July 12th and 13th, 2023. The 300+ delegates at the Forum networked, shared best practices, and got an overall view of market trends and requirements. In the session on Digital Transformation and Sustainability Initiatives (Part 1), Vikas Manoria, Head, Regional Product Management, Factory Automation, Digital Industries, Siemens Limited, provided the industry perspective about all-pervasive Artificial Intelligence (AI) within the preview of Edge computing in manufacturing. This blog captures the salient points of Vikas’ presentation. It can be viewed in entirety here.

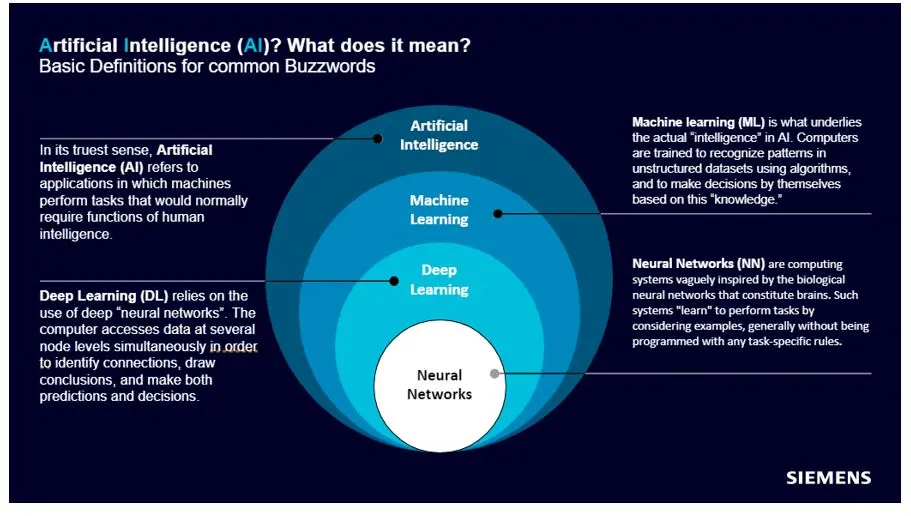

The importance of AI in industry is growing and some of the current applications are in product design, inspection, and process optimization. In the manufacturing landscape, the leaders in implementing AI are: North America, Europe, and the Asia Pacific region (mainly China and Japan). The level of AI implementation in India is slowly picking pace and it is poised to become a major AI player. Further, Vikas defined AI and other buzzwords, such as machine learning which are often used interchangeably. AI is the overarching system (could be a computer or machine) that uses data to learn the underlying pattern and make predictions. AI literally mimics human intelligence and makes cognitive decisions based on the available data. The graphic below defines the various buzzwords.

Further, Vikas spoke about how the programming differs for AI vs. a PLC. There is a paradigm shift as the PLC programming can reproduce a known rule; whereas ML can estimate a hidden rule based on its algorithms and tools. “This doesn’t mean that PLCs have become redundant, and AI is applied everywhere,” explained Vikas. An important part of the AI project is to decide which part of the plant/process/ machine an AI system will be deployed. AI is being used in a wide range of industries from automotive, water, electronics, metals, machine building and so on. There is significant increase in number of AI applications for Industry.

Everyone uses Edge devices – the most ubiquitous one being the mobile phone. In simple terms, Edge computing closes the gap between automation and cloud. In the industrial space, cloud computing came first and then the Edge. So, we’ve got accustomed to the data being sent to the cloud and the analytics being done there through high level languages like Python, C++ etc. Industrial Edge gives you the possibility of doing similar things at the Edge of your network, i.e., at the plant or machine level.

Physical (round trip times, bandwidth)

Legal (data ownership, liability)

Economic (transfer, storage, computing cost)

Additional functional enhancements of shopfloor devices

Enables short innovation cycles of IT in automation

Vikas explained the Industrial Edge architecture at the field level, factory level and cloud level. The data is collected and processed at the field level in Edge Devices and used for visualization and analytics. The Edge Management at the plant level plays an orchestrator role, managing the Edge Devices and Apps. Non-critical production data could also be sent to the cloud for further processing. AI on the Edge gives a lot of flexibility for the user and for the usage of high-level languages. It is also very easy to deploy AI algorithms on the Edge. All these factors point toward huge future potential for AI applications across industries.

He also explained the basics of AI on Edge platform - data is collected from the machines and pre-processed in the Edge Device; the pre-processed data is then sent to the cloud or a local server. Once the data is ready, it will be used to train the model through various machine learning algorithms and is again deployed back to Edge Devices for inference.

Vikas spoke about how Siemens is facilitating the perfect integration of the OT world (represented by the automation engineers) and IT world (represented by data scientists). It all starts by defining the business use case, planning the project scope and data requirements. AI models are created, and the collected data is labelled and trained using the domain expertise. The validated model is then deployed through an Edge app on the Edge devices. Based on the deployment you can sense, infer, and monitor the output. If necessary, the model can be retrained.

Next, Vikas touched upon Siemens AI with Purpose and the applications being built for the benefit of industries. Some of these applications have been released, some are in the pilot phase, some are on the verge of releasing, and many are in the development phase. A lot of these apps are being developed in India too.

Client: India-based OEM that supplies machines to global customers.

Requirement: Centralized monitoring of vibrations, machine and production performance with predictive maintenance for these machines.

Siemens’ Solution: Combined IT and OT technologies to monitor and predict machine anomalies with AI at Edge solution. Industrial Edge and Insights Hub were used. AI models will be used to make predictions and a new app is being developed for this customer. Further, new business models can be developed and monetized.