Show me the money. Show me the money, Jerry! The memorable lines spoken by Cuba Gooding Jr as footballer Rod Tidwell to his underperforming sports agent Jerry Maguire, played of course by Tom Cruise in the 1996 movie. It’s a sentiment that could well be applied to the industrial world and digital transformation. Because while end users are getting a better understanding of the enabling digital technologies that have come to the fore in the last five years and how to judiciously apply them in an organizational context to realize business benefits, there’s nothing quite like watching and learning from others who have embarked down the IoT and digital transformation path. What made you start? What did you actually do? Who did you partner with? What challenges did you face? What’s the next step? And after all that, are you saving or making any money? Come show me, please.

A good place to get answers to those questions was last month’s Industry of Things World Asia show, organized by Berlin based we.CONECT, which returned to Singapore for its third edition. As indicated by the name, the event’s emphasis is firmly on the industrial strand of IoT, making it an attractive forum for delegates from manufacturing industries and for technology suppliers like Rockwell Automation, which this year upped its sponsorship to become Lead Partner.

As with the two previous editions, the high proportion of end user presenters allowed for dissemination of a wide variety of real-life, cross-industry case studies. So in the spirit of learning, let’s take a look at some of the user stories presented at Industry of Things World Asia 2019.

For data storage systems manufacturer Western Digital, which has more than 70,000 employees around the world and multiple production sites, predominantly in Asia, the impetus for embarking on its SMART Factory initiative was the desire to become a data and insights driven business and achieve performance improvements in the areas of quality, asset utilization, labor efficiency, and cost. As presenter Philip Bernard, vice president of global HDD (hard disk drive) operations & engineering, outlined, operational realities in its manufacturing include high product complexity (250 components make up the typical hard drive), long cycle times and high unit volumes.

Western Digital’s highly structured approach to the its SMART Factory initiative comprised the stages of providing organizational direction by formulating corporate strategy (playbook) and preparing a SMART Factory blueprint; setting project directions and necessary leadership by outlining cross-functional stakeholders alignments on objectives and expected outcomes; and finally, business execution and operationalization. And to accelerate adoption and acceptance the company used the Minimum Viable Project (MVP) approach: Think Big − Start Small − Scale Fast.

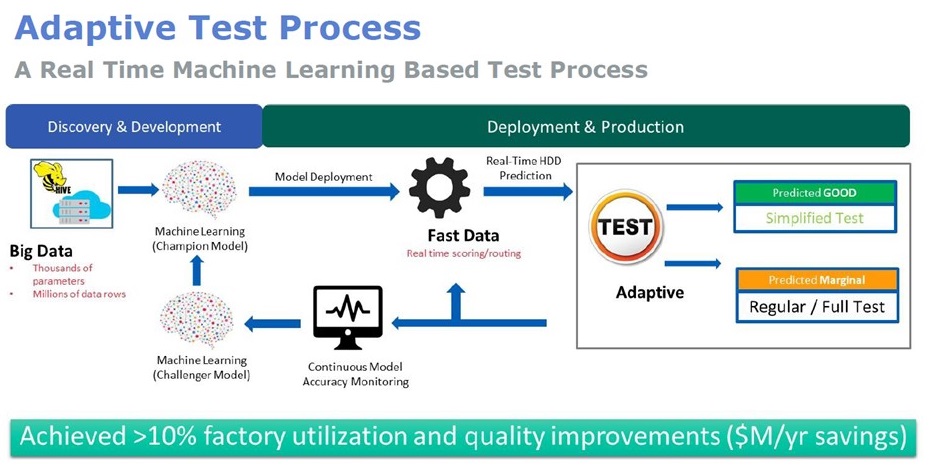

One example of SMART Factory success is the implementation of a real-time machine learning based test process, which predicts which HDDs are likely to pass product test and so can go through a simplified test process, and which are likely to fail and hence require regular full test.

The Adaptive Test Process has led to savings in the order of millions a dollars a year through improved test equipment utilization and higher product quality. The project also provides a good illustration of the Western Digital’s MVP approach in action: Think Big − let’s get the ability to anticipate product quality; Start Small − start out with one product and enable initial automation to support it, which will help us build trust in using AI to automate decision making; Scale Fast − extend to more product lines by leveraging on the same automation but scaling the infrastructure.

Shaun Gregory, executive vice president and chief technology officer at Woodside, Australia’s largest natural gas producer and a pioneer of the LNG industry in that country, echoed Western Digital’s approach to digital transformation in his presentation about the company’s adoption of IoT and artificial intelligence, Think Big, Prototype Small, Scale Fast.

Make sure you’re working on a big problem, says Gregory, because there’s a risk in deploying new technology and that risk has to be worth it. “So think big because if what you’re planning is going to make a one percent improvement to cost then I am not interested. But if you say you’re going to halve my cost you have my attention – and some seed funding. Prototype small is about telling people to stop writing business plans and give it a go – quickly and at low cost. And because you lower the consequence of getting things wrong , as long as you learnt something, I don’t really care if you fail. Then once you have a working prototype, if you do not scale this into your business then that is the real failure because you won’t reap the benefits you anticipated.” The Woodside CTO admitted that scaling solutions is an aspect the company has struggled with in the past.

One IoT prototype project described by Gregory took place in a water treatment plant section of an LNG complex, involved a pump with a visual oil level indicator. Previously, a staff member had to trek out to the plant, which is located in a remote area subject to temperatures of 40 deg C, note the oil level, and enter the value once back at their PC. Rather than go the expense of retrofitting the equipment with a digital sensor, Woodside uses a camera to take a photo of the indicator level at one hour intervals. The data goes to the IoT cloud where a machine learning algorithm that deduces the percentage oil-fill level, with the value displayed on the digital twin representation of the plant.

Usefully eliminated are the uncomfortable, time consuming, non value-added steps of manual check and data entry. And importantly, as Gregory pointed out, the project increases workers’ awareness and builds confidence in new technology, making it easier to successfully scaling to other applications in the LNG complex.

HVAC services company Comfort Systems USA, which claims more customers than any similar organization in America, operates in a business environment where the labor pool is aging and most (85%) HVAC equipment is more than 10 years old and lacks any kind of on-board monitoring technology. The high-margin HVAC maintenance business is, however, lucrative and important for Comfort Systems, accounting for half of profits. In order to maintain its edge, the company needed to look at how technology in the form of IoT could improve both the customer experience and the field technician experience.

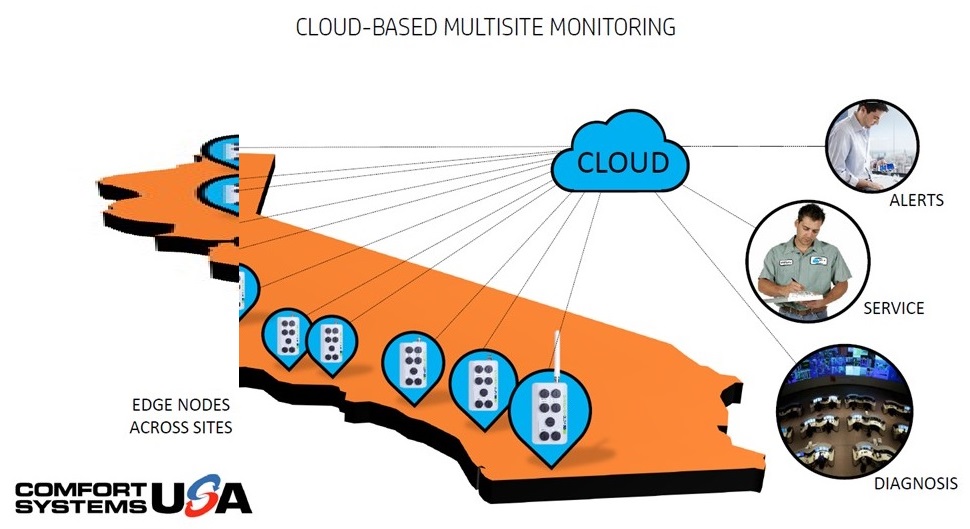

As the company’s CIO Jeremy Jones explained, the HVAC service process had remained unchanged for many years: Dispatch a technician to the customer location; Technician does on-site diagnosis and makes appropriate repairs; He provides handwritten report to customer detailing work completed; Customer is invoiced and CRM data is updated with latest information. The IoT system now in place comprises multiple sensors – pressure, temperature, humidity, current, etc – fitted to a customer’s HVAC unit and the data is communicated via edge node and GSM cellular gateway to a Google cloud hosted application for access by customers and field technicians.

The capabilities the IoT system brings include predictive monitoring and maintenance, which means that the company can make useful early detection of adverse equipment situations and optimize deployment of its field technicians. For example, a client’s electricity bill could have been rising in recent months but that customer may not necessarily connect that to the cause i.e. a lack of refrigerant in the system. So rather than waiting for a customer to contact Comfort Systems when the problem becomes more obvious, the company can deploy a technician to fix the problem. The result: higher customer satisfaction. Other customer experience improvements include more detailed service reports and greater ease and transparency of billing. Working with new technology is also helping Comfort Systems to retain and recruit staff, with the average age notably less than that of competitors.

What about show me the money, you may ask? CIO Jeremy Jones: “It’s now easier for customers to do business with us and we win more work when they see all these new capabilities. When we started this project our revenues were $1.7 billion and they’re now $2.4 billion. That’s a $700 million increase in three years and half of that is directly attributable to our IoT efforts.”