Most industrial/commercial asset management systems focus on maintaining manufacturing or process assets. This applies whether the asset is a machine, pump, compressor, wind turbine, or building. Asset operation is typically handled by control systems that help the operator achieve the operating objective. Control systems keep wind turbines safe and efficient. Building controls keep the occupants comfortable by regulating temperature, humidity, lighting, and power management.

Both asset management and control systems use data as inputs, but control systems act on that data with algorithms; directly manipulating actuators like valves, solenoids, and electric servo motors. Asset management systems, in contrast, use calculations and trending of KPIs, dashboards, and data analytics. Asset management system outputs tend to be alerts and provide information to the operator about some aspect relating to performing. Low asset performance usually means maintenance will be prescribed, but it could also mean the operator needs to perform an action. However, asset management alerts do not always direct the operator to a specific action. To use an example from our daily lives, the “check engine” light in your car might alert you to a possible problem but gives no indication about what that problem might be or how it should be repaired. Similarly, in many cases, the operator needs to look more carefully at the situation and decide what to do about it. Increasingly, asset management systems are guiding plant operations at speeds near real time and not merely suggesting maintenance.

Nalco Water, an Ecolab company, has developed an asset management system for steam power systems. Significantly, the Nalco Water application provides both operational and maintenance assistance. Developed by chemists and process engineers, Nalco Water’s application can work at multiple sites within a company and at multiple companies. Nalco Water worked with Accenture, Microsoft, and OSIsoft to create a reusable cloud-based solution. The key requirements were to collect the right data into a data platform that connects to Nalco Water’s cloud-based OMNI analytics tool. The company staffs an operation center 24/7 that can monitor steam power plant systems operating at multiple sites and alert plant operations and maintenance when conditions stray away from optimum operating points.

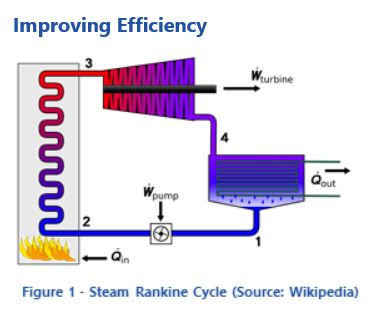

The heat engines at power plants often use steam as the working fluid with a heat source, steam turbines and condensers. Managing a large asset like this requires skilled operators 24/7. Due to the large scale of most power plants, many factors i

The second law of thermodynamics has always been a limiting factor for thermal power plants. The working temperatures of the engine cycle influence the conversion efficiency of heat into work. One way to improve the conversion in a steam cycle engine is to keep the sink temperature or condensing temperature as cold as possible. Heat transfer is limited by air or water temperature. Operation of thermal engines like the steam-based, Rankine Cycle Engine, in cold winter conditions can significantly improve thermal efficiency compared to operating in warm summer temperatures. A small difference in steam condensing temperatures can improve the heat rate of a power plant by more closely operating near ambient temperatures. A scaled or fouled condenser will reduce efficiency and waste fuel.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Power Plant Efficiency, Asset Management, Plant Operations, Maintenance Management, Cloud Computing, Analytics< Arc Advisory Group.