Put simply, Enterprise Asset Management (EAM) systems are used by the asset owner and/or operator to manage the maintenance of their physical assets. These assets including equipment, buildings, vehicles, and infrastructure need maintenance to sustain their operations. An EAM system provides the means to have less unplanned downtime and extended asset longevity, which has clear business benefits that improve the profit and loss (P&L) statement and balance sheet.

Particularly for capital-intensive industries, failure of critical equipment is disruptive and costly in labor, in-process materials, and customer satisfaction. Regulated industries having FDA oversight require records for process maintenance with an audit trail. At the same time, personal safety is a concern including compliance with occupational and environmental safety regulations. Organizations understand these issues and employ a maintenance organization to sustain their assets. An EAM system is needed to manage the people, parts and workflows.

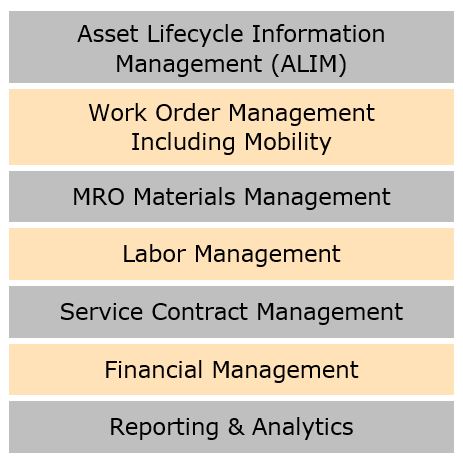

EAM is used to plan, optimize, execute, and track the needed maintenance activities with the associated priorities, skills, materials, tools, and information. The cost accounting provides cost allocation to the operating units. Project costing provides the start for capitalization and depreciation. The functions for EAM are categorized in the table, and include asset information, work orders, MRO materials, labor skills, service contracts, finance, and analytics. Computerize Maintenance Management System (CMMS) is an older term that is continues to be used to describe this type of software.

Industrial IoT (IIoT) and analytics are being adopted for predictive maintenance. When an asset's health becomes a concern, an alert goes to the maintenance planner who creates a work order to address the issue before it becomes unplanned downtime.

Mobile devices allow the technicians to process the work order while they are doing the work. This transition from paper to electronic devices improves data quality and integrity. The EAM or CMMS system becomes a trusted work planning and execution tool for the management of people, parts, information and priorities.

For more trends, go to: Past, Present, and Future Trends in EAM and CMMS

This market research study provides current market analysis plus a five-year market and technology forecast. ARC derives market size and share from its extensive in-house databases and in-depth interviews with leading suppliers. The EAM market study may be purchased as an Excel workbook and/or as a PDF file.

This Technology Selection Guide is designed to help organizations navigate the buying process for EAM systems. ARC determines selection criteria through research with users and an understanding of supplier capabilities. The EAM guide includes both selection criteria and strategies for choosing the best enterprise asset management software supplier to meet your business needs.