Schneider Electric participated as a Silver Sponsor at ARC Advisory Group’s 21st India Forum titled Driving Sustainability, Energy Transition, and Performance through Digitalization on July 12th and 13th, 2023. The 300+ delegates at the Forum networked, shared best practices, and got an overall view of market trends and requirements. In the Forum session on Digital Transformation and Sustainability Initiatives (Part 2), Kirankumar Vyas, Head of Business Development, Process Automation India and Pulak Upadhyay, General Manager, Digital Consulting, Process Automation India, Schneider Electric spoke about improving the green hydrogen business value chain. Pulak gave a brief introduction before handing over the reins of control to Kirankumar. His presentation had short, self-explanatory videos about the company, green hydrogen, and sustainability. Sustainability is at the core of the company’s operations, in their factories, processes, products, systems and what they deliver to their customers.

Company’s mission: To be your digital partner for sustainability and efficiency.

Company’s purpose: To empower all to make the most of our energy and resources.

This blog captures the essence of Kirankumar’s presentation; it can be watched in its entirety here.

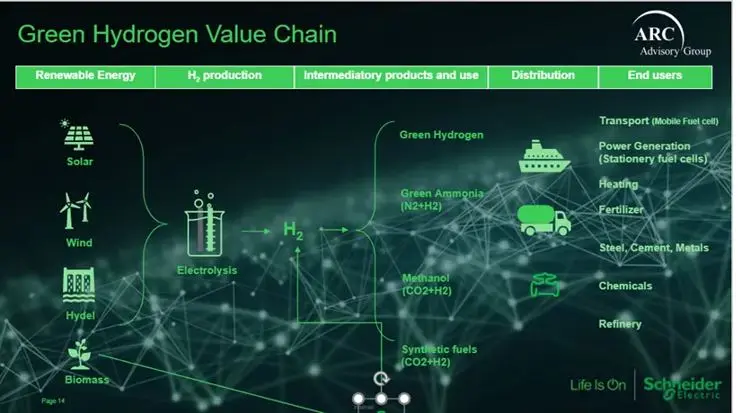

When senior management is approached about a new development or deploying a new technology, the typical response is “Where is the money?” Kirankumar explained that there is money in the green hydrogen value chain. He highlighted green hydrogen’s role in achieving net zero emissions that companies and countries have to aim for and collectively optimize. There’s an ongoing debate about renewable energy versus green hydrogen. The solution would be renewable energy plus green hydrogen – because renewable energy is required to generate green hydrogen. But the main challenge in using renewable energy is long-term storage and if big batteries are used the recycling process will cause pollution.

“The world is moving from non-green to green energies,” said Kirankumar. Climate change has emerged as an important issue the world over and can no longer be ignored. Electrification has to be adopted as a clean and sustainable solution to many of our transport and industrial needs. Majority of electricity is generated from sustainable sources such as wind and solar, but these sources are inadequate to fuel heavier modes of transport like buses, lorries, and ships – and that’s where hydrogen comes in.

Although hydrogen is a colorless, odorless gas, colors are used to describe it based on the production process. Gray hydrogen is produced from natural gas and creates CO2 in the process; in the future blue hydrogen will also be produced from natural gas and most of the CO2 will be captured and stored; green is the cleanest form of hydrogen produced from renewable energy with zero CO2 emissions. Green hydrogen is versatile and it can be created, stored and transported based on the requirement.

Green Hydrogen in India

There’s a major push for green hydrogen in India and the government has formulated policies like the National Hydrogen Mission and pledged to make India a global hub for green hydrogen production and export. Recently, India launched schemes worth Rs.17,490 crores to drive electrolyzer/green hydrogen manufacturing.

The challenges on this journey pertain to: cost, safety, scaling up, and flexible operations.

Solutions: Reduce cost of electrolyzers (CapEX); improve economics of operations (OpEx); ensure availability of renewable energy; distribution network; regulatory framework and mandates to boost consumption.

A lot is being done by the government, but instead of preaching as to what others should do, technology providers must effectively collaborate for better integration of processes and systems. There should be open protocols and a single platform for better integration, interoperability, and safety. This will accelerate the speed and adoption of green hydrogen among the mid and small players too.

Integrated open automation for entire value chain: Use of Open, Universal Automation; collaborate to integrate power and process automation. The benefits are a drastic reduction of automation costs and carbon footprint.

Integrated open Metaverse for entire value chain: Use of interoperable open enterprise Metaverse; Metaverse across the entire green hydrogen lifecycle (project and operations); and integrated end-to-end digital twin.

The green hydrogen value chain becomes more efficient with digital and electric. Digital makes the invisible visible, measurable and actionable; electricity makes energy efficient and helps to decarbonize operations. Further, Kirankumar spoke about scenarios where complex solutions were deployed and highlighted a power system design optimization case study.

Integrated sustainability monitoring for the entire value chain: Collaborations to accelerate climate commitments; three-step approach and integrated framework to sustainability transformation – strategize, digitize, and decarbonize.

Integrated safety for entire value chain: Integrated lifecycle approach for safety monitoring and management; be prepared to tackle the AI (Artificial Intelligence) race for attackers and defenders of cybersecurity; there has to be integrated safety (functional + cyber + AI) monitoring 24/7 for all industries.

In this context, Kirankumar spoke about Ethos, Schneider’s OT-centric, open-source platform for sharing anonymous early warning threat information. The final message was: Green is the path ahead, and together we should build a more sustainable world.