In my last blog, I discussed the idea of two views of the industrial edge - operational and infrastructure. Today, I'm going to turn the lens toward the next obvious step in leveraging the industrial edge: determining when to use edge or cloud analytics. Both should be considered, used, and eventually integrated, but starting points for each of them begin with different business objectives.

The already-low costs for distributed compute power and communication continue to decrease further, while edge processing power is increasing exponentially. What wasn’t technologically viable a few years ago, now is. Now, data can be considered processing based on where it delivers most value.

So then, when should an industrial business deploy edge intelligence? The quick answer is that all industrial companies using IIoT data will eventually need edge analytics based simply on the nature of their operations. In terms of when to use edge analytics, a more thorough explanation includes a mix of technology and business reasons.

Sporadic connectivity in industrial environments is common. In some harsh or distributed-infrastructure environments, it is non-existent. Even when available, the location of the network edge often constrains bandwidth. Cloud-based applications typically rely on maximum compute power and bandwidth that make then untenable for those limited-connection edge environments. Additionally, at the control and automation layer, legacy OT systems weren’t designed with the type of data connectivity and sharing IIoT use cases require, so they simply can’t support exception-based management common to many IIoT use cases.

Along with connectivity, immediacy of decisions is the other most obvious reason for keeping analytics as close to the edge device as possible. Instantaneous decisions are often necessary in operations, particularly when it comes to assets. In some operational processes, delays can lead to catastrophic failure, process shutdowns, and even death. For example, consider brakes, elevators, and industrial sites with hazardous off-limit zones. Using edge analysis, devices can assess their operational health and enact appropriate measures to eliminate failures or, if necessary, minimize their impact. This can often be done in several milliseconds, versus the more typical 100+ millisecond delay if the data had to flow to and from the cloud.

As IIoT devices proliferate, a sheer volume and velocity of data is continuously generated by edge devices. Most data don’t show changes and so are uninteresting. If that data is sent to the cloud, it must then be filtered from the computational process since it is irrelevant to supporting the use case. In contrast, edge intelligence can provide monitoring while filtering what data gets sent to the cloud. Also, since machine learning can’t really operate off raw streaming data, cleaning and enrichment at the edge helps to ensure the data arrives to the cloud ready for additional uses.

The expense of data noise must also be considered. For example, a single oil rig has tens of thousands of separate data points producing terabytes of data annually. As this data is aggregated across a fleet of rigs, the cost of sending of transporting, ingesting, storing, and filtering all that data quickly scales. Given that oil and gas companies are focused on cost containment, the added expense of cloud-only intelligence isn’t sustainable, particularly as the data volume continuously grows. This problem is magnified since there is no return on that invested cost, as much of that cloud-stored IIoT data would contain no business value.

In some cases, regulations or customer choice prohibits transferring data away from an edge source, but analytics are still needed to run the product or service correctly. An example might be operating an electric vehicle and charging station. Here, analytics might be necessary to manage battery health or determine maintenance needs proactively. However, the operating agreement with customers might limit the amount of individual passenger information (such as locations visited) passed along to the enterprise data layer.

Often, security vulnerabilities are minimized by limiting physical and cyber access to data-generating assets. Network edge intelligence can be used to wall off data to prevent mis-operation or unauthorized use, while enabling the intelligence to be used to help ensure mission-critical resource availability. An example here could include a microgrid at a hospital or emergency event center, where the addition of edge intelligence could double the security benefit. First, it disperses access by bad actors away from central systems. Secondly, it ensures no single point brings down the operation, based on the many ways accidental cascading failure can occur (humans, software, hardware, etc.).

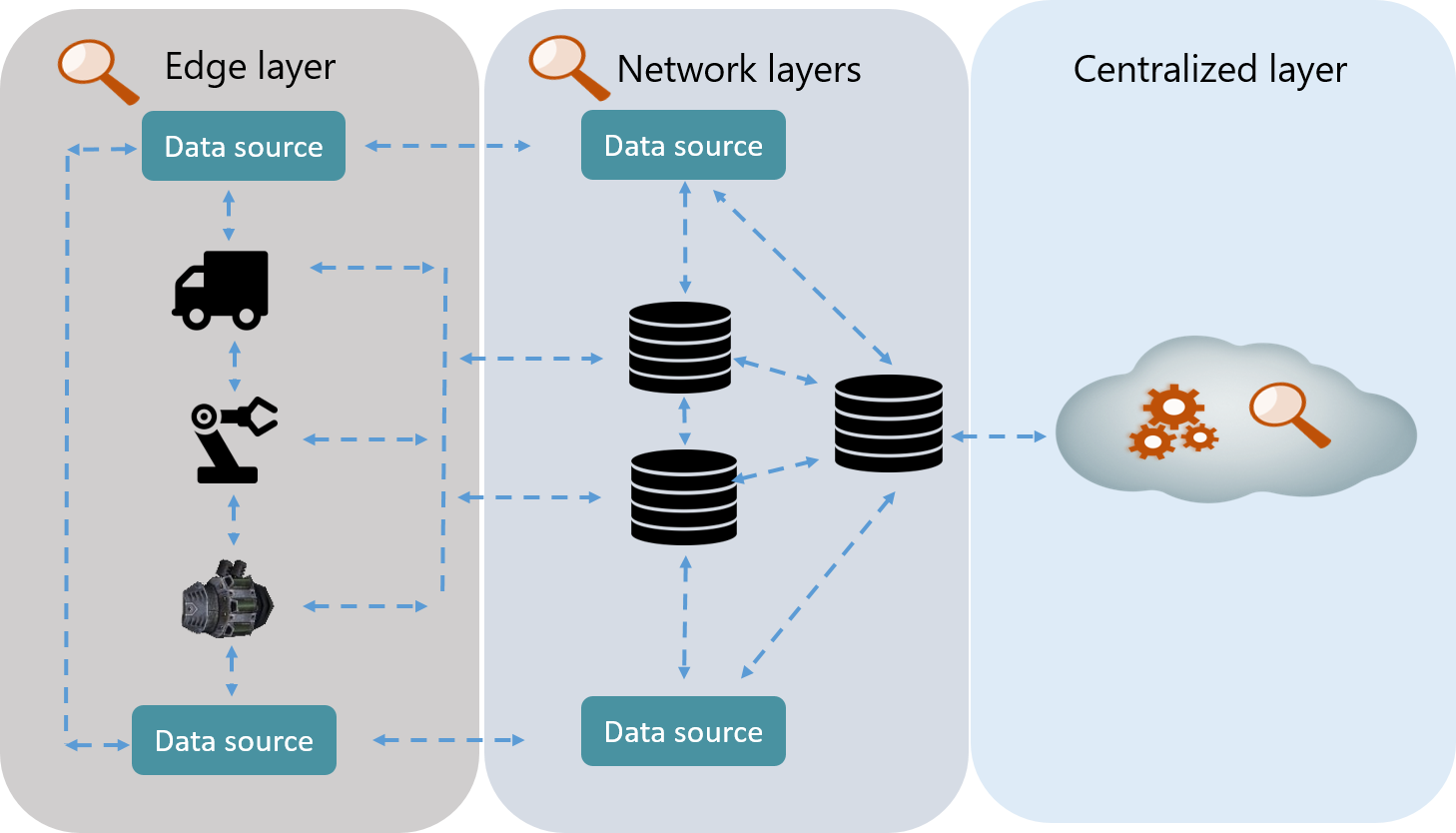

In some instances, data needs to be processed centrally, such as in a cloud, to drive strategic decisions. In other situations, decisions will need to be instantaneous, meaning that centralized solutions cannot be used. Ultimately, industrial organizations will move beyond arguments for edge or cloud analytics by embracing edge and cloud and analytics layers in between.