ABB participated as a Global Sponsor at ARC Advisory Group’s 21st India Forum titled "Driving Sustainability, Energy Transition, and Performance through Digitalization" on July 12th and 13th, 2023. The 300+ delegates at the Forum networked, shared best practices, and got an overall view of market trends and requirements. In the Forum session on Industrial AI and Analytics, Rajesh Ramachandran, Global Chief Digital Officer, Process Automation, ABB spoke about how to derive business benefits by applying industrial Artificial Intelligence (AI) at scale.

Giving an overview of the company, Rajesh said that ABB has been a leader for more than 100 years in the area of industrial automation electrification and for over a decade on digitalization. His presentation lucidly covered four aspects:

Industrial AI and its role

Applying industrial AI at scale

Proven use cases and case studies

Generative AI in industrial applications

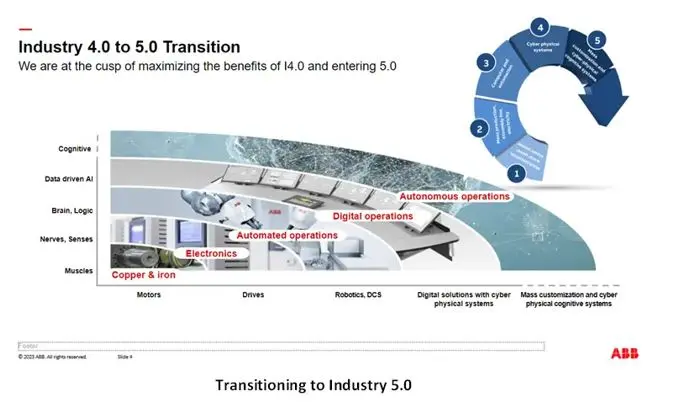

The three major shifts that we are witnessing today: sustainability and energy transition, automation and digital transformation, and the changes that globalization brings. “Those in the room are very fortunate as we’ve been through the three industry revolutions, which neither our ancestors nor followers will be able to,” said Rajesh. We’ve seen the transition to Industry 3.0 – 4.0 and now entering 5.0. We are at the cusp of maximizing the benefits of Industry 4.0, which is a data-driven way of creating a digital model with a cyber physical system for remote operations. Organizations are at different stages of reaping the benefits of digitalization, and those that have already adopted this have seen significant value. We are heading toward mass customization and personalization.

Industry 5.0 deeply connects the cognitive (human centricity) to artificial intelligence. It combines the creativity of human experts with efficient, intelligent, and precise machines to produce user-preferred manufacturing solutions. Cognitive cyber-physical technology will enable Industry 5.0 to boost productivity and deliver spontaneously customized products.

Five years ago, AI was just seen as another technology; but today industrial AI is mainstream and has to be applied at scale to deliver value. The business and technology priorities and objectives have driven the adoption of Industrial IoT and AI. The business angle covers the gamut from digital value applications, remote digital operations, holistic asset performance management, and the connected worker; the technology priorities to meet these objectives include rapid convergence of industrial IoT and industrial AI, extended automation and OT transformation, Edge AI optimizers, and digital twins. The clear value is authenticated by hundreds of customers across industries that are going beyond proof-of-concepts and are engaged in global rollouts of industrial AI and IoT applications.

“It all begins with the data,” said Rajesh. When that is combined with a component – IoT, domain, AI it leads to digitalization; this needs to be scaled with the three elements – value engineering (data contextualization/readiness), business model (self-funding, not a CapEx), and change management to derive value. This is digital transformation and brings a real value at scale of driving business outcomes. The final value could be energy saving or increasing the safety/sustainability/asset life.

Further, Rajesh spoke about industrial AI, which is an ensembled approach (data-driven AI model + domain model) for safer, smarter, more sustainable operations.

The AI paradigm is shifting and now there are two different AIs – Analytical AI and Generative AI. While Analytical AI includes machine learning, deep learning, reinforcement learning, digital twins etc., Generative AI is more about text/code/image/voice/video generation, smarter virtual assistants and so on.

Speaking about applying industrial AI at scale, Rajesh gave the example of the eight capabilities of ABB Ability Genix Industrial IoT and AI Suite that ensures that the contextualized data for implementing the AI is available all the time. This enables the six key digital value pillars – sustainability, operational excellence, process performance management, asset performance management, cybersecurity, and extended automation and OT transformation. Thousands of Genix pre-built industrial AI models are available. “Adoption of digital twins can be accelerated by AI,” explained Rajesh. Ultimately, AI unlocks the value of data, and industrial value pillar applications drive business outcomes.

Applying industrial AI at scale across industries effectively demonstrates the business benefits. The following use cases were highlighted.

Industrial AI at scale in a fleet of industrial analyzers: AI enabled continuous emission monitoring and optimization.

Remote operations for a marine fleet operating center: Real-time industrial AI powered remote operations, asset performance, and sustainability.

Holistic asset management: End-to-end asset performance management across industries. AI-based predictive maintenance, asset reliability and integrity, and digital twins.

Energy optimization: Edge AI MPC cooling system optimizes energy and reduces cooling load.

Anomaly detection in system/asset process: Industrial AI at scale increases availability, performance, quality, and avoids process upset conditions.

Process performance management and optimization: Industrial AI minimizes process quality deviations and ensures continuous improvements in operational performance.

Generative AI can help in continuously optimizing both at the enterprise and unit levels. In this context, Rajesh spoke about the collaboration with Microsoft to bring Generative AI to industrial applications for operational excellence. Soon to be launched Genix Co-Pilot will make a dramatic difference to the user experience by enhancing the value of contextualized data and accelerating digital value creation.

ABB is making significant investment in Generative AI to ensure that its industrial customers manage and optimize sustainability, operational excellence and asset reliability. While sustainability is important, it has to go hand in hand with operational profitability and asset performance. Industrial AI at scale delivers tangible business value by streamlining processes, improving operational efficiency, and enabling predictive maintenance.

From August 1st – 31st the video of this presentation will be available here.