A major agricultural, food and animal feed company uses artificial intelligence enabled predictive data analytics and a robust data infrastructure to predict the process end for its fermentation products based on sensor and analyzer information, batch conditions, and other process data available in its data infrastructure. The production company believes it will obtain significant value from the pilot by applying the technologies to other applications throughout the enterprise. Because there are many different types of analytics and tools available today, the agricultural company’s technology group reviewed what types of analytics they should be applying and where to apply it.

Previously, the company had been using the more traditional method of model predictive control (MPC) to determine the behavior of their fermentation processes. MPC is the more traditional methodology used in the process industries, and is based on predictions for a fixed time horizon using linear models. This method is iterative, time-consuming and tedious, and is generally performed by expert(s) with strong process knowledge and mathematics skills. Often the data drifts or something in the process changes, requiring an updated model to accommodate new constraints.

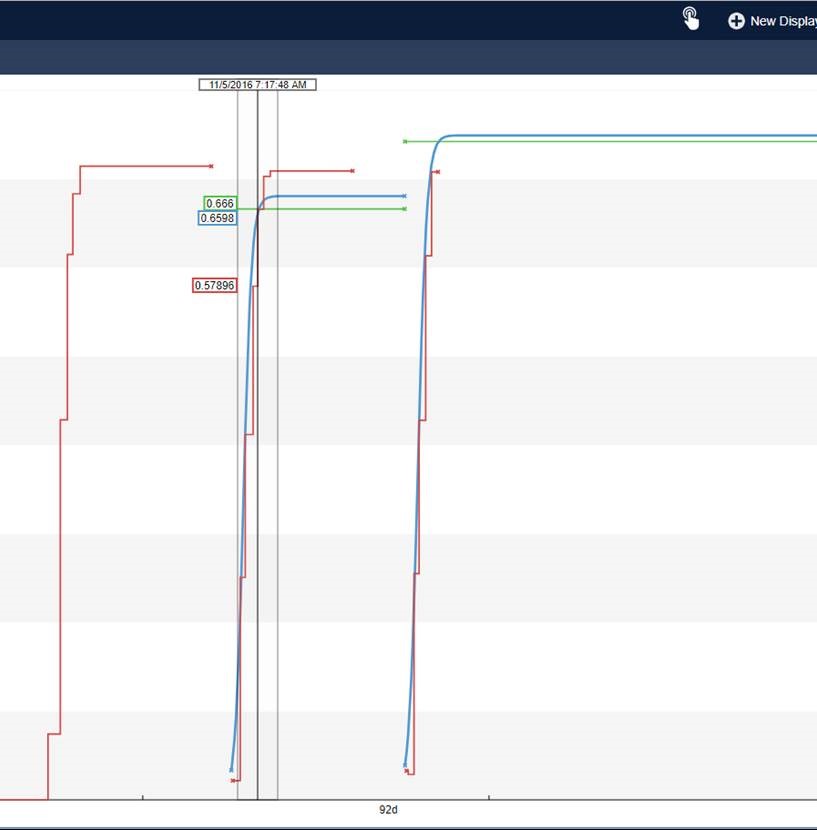

Using automated analytics with artificial intelligence – the predictions are based on the actual data collected in the data infrastructure directly from the process. The tool enables the ability to utilize non-linear models and the ability to update the models automatically based on new data and process changes. The predictive model learns and becomes smarter with each new data input, enabling a much higher level of accuracy in the process predictions.

The latest ARC insight on this topic (link goes to client portal) illustrates how automated analytics were used on a fermentation process to accurately predict the end point and increase productivity and asset utilization by 5 percent.

In this case, the company desired analytics that were applied to real time manufacturing operations. The company used analytics powered by artificial intelligence to optimize its lysine production process to reduce the time required for the fermentation.

Due, in part to advances in data infrastructures and predictive analytics, the use of artificial intelligence and advanced analytic technologies is growing rapidly. The right data infrastructure in place for managing, contextualizing, and connecting the data, combined with the right AI-enabled analytics technology, can provide an industrial organization with a competitive advantage. But only if that organization can also support a data science culture from the top down starting with the data infrastructure.

ARC recommends that companies with complex and/or dynamic processes explore the potential benefits of utilizing predictive (or other) analytics to improve production. believes that the technology can be applied to many other processes, particularly other inherently dynamic biological processes used in the pharmaceutical, biotech, and brewing industries.