In today’s energy-intensive environment, pipelines provide a relatively safe and reliable way to transport the world’s most vital resources. Approximately 70 percent of all petroleum and crude products are moved via pipeline, according to the Manhattan Institute. Pipelines have proven to be the safest mode to transport oil and gas due in part to enhanced construction and welding techniques, combined with continuous advancements in leak detection technologies. However, a 1 percent leak in a 20-inch line can rapidly translate into a loss of 450,000 barrels a year and, if left undetected, could contaminate 10 square kilometers within 24 hours. Detecting pipeline leaks is a critical function for midstream companies to maintain operational performance and regulatory compliance. Additionally, with millions of miles of auxiliary oil and gas pipelines and pipe networks spanning throughout the U.S., leak detection systems (LDS) are a crucial component of ensuring all products are delivered safely, on time, and in an environmentally responsible manner.

Previous methods of detecting leaks relied heavily on human intervention and calculating pressure drops to determine if and where a pipeline may be leaking. While these methods offer valuable detection techniques, pipeline operators today are moving toward digitized processes that involve wireless electronic systems coupled with complete integrity management systems to provide a higher level of pipeline safety and leak prevention.

These systems generally fall into two categories: Non-continuous and continuous.

Inspecting pipelines by helicopter, smart pigging, and even tracking dogs fall in the non-continuous category.

Continuous systems are further divided into external- and internal- based systems. External continuous systems include: fiber optic cable, acoustic systems, hydrogen sensing cables and infrared. Internal systems include: negative pressure wave, mass/volume balance method, statistical analysis, real-time transient model (RTTM)-based systems, and extended RTTM (E-RTTM). In practice, non-continuous systems are often used in conjunction with continuous systems.

End users have been pressuring suppliers to develop even more effective and accurate leak detection system that don’t require them to pay for unneeded functionality. In response, suppliers are developing more modular solutions that can function as components within a comprehensive pipeline integrity and monitoring system.

ARC recommended that operators and users consider several different technical and commercial factors before making a purchase decision. Factors to consider include: age of pipeline, pressure requirements, composition of medium (liquid, gas, multiphase), Accuracy of system (i.e. localization, volume detection, etc.), responsiveness of system, ease of use, training requirements, overall system reliability requirements, and the ability of a given system to mitigate false alarms, among others.

With a real-time leak detection monitoring solution, the user will be immediately alerted if there is a leak, which allows fast response to minimize the impact on safety, the environment, operational performance, and profitability. ARC research indicates that the latest cloud-based leak detection systems are easy to operate and can reduce labor requirements. However, initial acceptance of these solutions is expected to remain relatively low due to the sensitive and proprietary nature of the data. Private cloud-based solutions provide a possible solution, but the costs involved and the need for in-house IT expertise will likely prohibit some companies from undertaking this course of action.

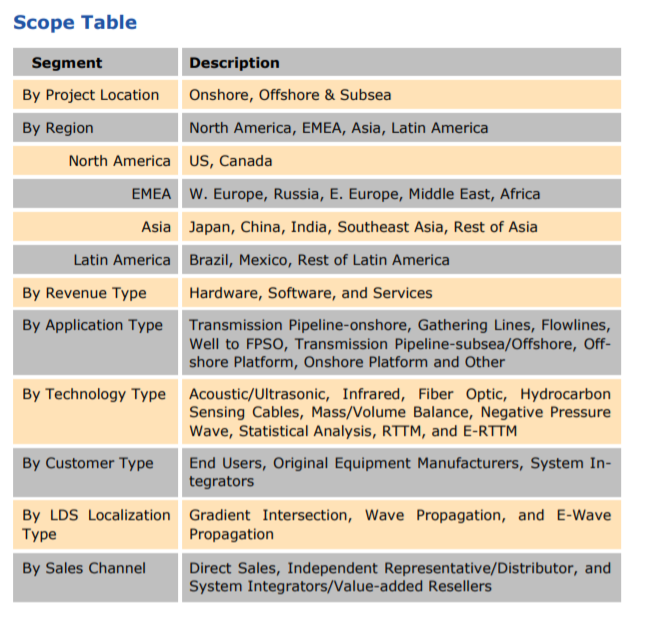

ARC’s new research report, “Leak Detection Systems explains how modern leak detection system can help maintain pipeline integrity, reveals which technology for leak detection technologies currently enjoy the largest market shares, provides and overview of the leading suppliers to this market space, and provides a detailed forecast on which regions will see the fastest growth.

For more information on this and other available ARC market research, please visit our Market Research and Studies section.