February 8-11, 2021 - Online

ARC Advisory Group’s annual Industry Forums, typically held in Orlando, Florida, always provide an excellent opportunity for the industrial world to come together to network and share learnings. This year’s Forum, held in hyperspace, continued that tradition.

Recent Forums have focused on the digital transformation of industry and infrastructure. According to at least one executive from a leading manufacturing company, these events have provided a “guidebook” for digital transformation. The online presentations at the 2021 ARC Industry Forum, Feb. 8-11th have revealed that targeted and effective application of digital technologies continue to lead to tangible business improvements at leading companies around the world. As we’re learning, digital technologies have also shown to be critically important for companies to function effectively with reduced staffs during the current global COVID-19 pandemic.

While the venue changed for this year’s Forum and everyone certainly missed the face-to-face contact and hospitality aspects of the previous events in Orlando, the Forum content has been as solid and informative as ever. The virtual, online environment – which eliminated many time, cost, and logistics hurdles - also enabled a record-breaking number of people to participate, both as presenters and attendees.

To kick off this year’s Forum, Accelerating Digital Transformation in a Post-COVID World, Andy Chatha, ARC’s President and CEO, stressed that this theme is particularly relevant for the time. He also mentioned that thanks to the virtual format, this year’s Forum features more global executive speakers and end user participation than ever before.

Lessons from the Past Year

Lessons from the Past Year

Before introducing the keynote speakers, Andy briefly shared some lessons learned collectively over the past year. These include:

- Disruption can happen faster than we can imagine

- Necessity is the mother of invention; we’ve all had to learn many new tricks at home and at work

- No one is immune, but impact can be uneven - from family to family, company to company, and country to country

- Our priorities can change quickly

- Resets are possible and can be galvanizing

- We, the people, can rebound quickly

- We need highly engaged employees for faster innovation and higher customer satisfaction

Digital Transformation at ExxonMobil

Nick Clausi, Vice President of Engineering at ExxonMobil Research and Engineering, provided the first keynote presentation from his office in Spring, Texas. Mr. Clausi explained that his engineering organization has two primary missions: provide technical support for day-to-day operations; and develop and ultimately deploy advanced new technologies that advance the company’s competitiveness. “To that end, our company has been on a digital transformation journey, probably not unlike many of the other companies here today. That journey has been focused on leveraging the rapidly advancing digital capabilities, data analytics, and innovation to improve the performance of our people and our facilities.”

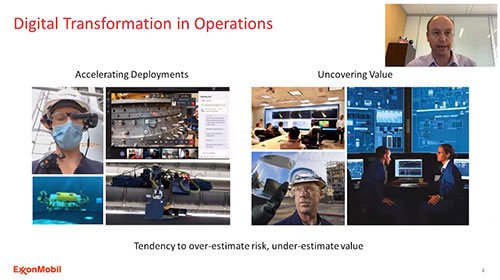

He shared some perspectives on what the past year has taught ExxonMobil about digital deployments and linked those perspectives to some of the company’s more aggressive digital transformation efforts: autonomous operations to help reduce complexity for the company’s process control operators, and open process automation (OPA), the industry-wide initiative that ExxonMobil executives first announced at the ARC Industry Forum several years ago.

Remote Connectivity

Mr. Clausi revealed that the COVID pandemic accelerated the rate at which the company deployed digital technology and revealed some previously unrecognized value from those technologies. Examples of the former include deploying remote connectivity tools to support factory acceptance testing (FAT). The pandemic also accelerated the company’s deployment of robotics for inspections.

Mr. Clausi revealed that the COVID pandemic accelerated the rate at which the company deployed digital technology and revealed some previously unrecognized value from those technologies. Examples of the former include deploying remote connectivity tools to support factory acceptance testing (FAT). The pandemic also accelerated the company’s deployment of robotics for inspections.

As an example of how the pandemic helped the company uncover previously unrecognized value from digital technology, he mentioned the company’s facility in Baton Rouge, LA, which has the world’s largest isopropyl unit. Isopropyl alcohol (IPA) is a key ingredient in hand sanitizers and disinfectant sprays, which both immediately became in short supply when the pandemic hit. Here, the company was able to leverage its remote connectivity tools with its advanced dynamic matrix control technology to rapidly and remotely update control modifications to go along with physical modification of the unit. This enabled the company to rapidly expand the IPA unit’s production capability to help meet the unprecedented and previously unanticipated increase in demand.

Another example relates to deploying a remote machinery monitoring capability developed by the company’s technical center in Malaysia. While working through an orderly shutdown at the company’s Beaumont, TX facility in preparation for Hurricane Laura, there were a reduced number of engineers onsite due to the pandemic. However, machinery experts located remotely in Malaysia had full visibility into the real-time data, enabling them to guide the site through the shutdown. In the process, those remote experts uncovered vulnerabilities that could have compromised an orderly restart.

According to Mr. Clausi, reflecting back on 2020, the key takeaway here is that, when it comes to digital technologies, “there’s a tendency to overestimate the risk, and underestimate the value. That’s a really important lesson for us to keep in mind as we pursue some of those more challenging digital technologies and applications.”

Digital Transformation at ADNOC

The next speaker, Alan Nelson, Chief Technology Officer at the Abu Dhabi National Oil Company (ADNOC), then discussed that company’s approach to and progress with digital transformation in the current pandemic-constrained environment. Mr. Nelson spoke to us from his office in Abu Dhabi, where it was still very early in the morning hours.

“Good morning, good afternoon, and good evening to our colleagues around the world,” he began. “There is no question that, today, we’re facing unprecedented challenges and opportunities at a pace that is unparalleled in recent memory. And the role of technology has never been more important to navigate the near-term challenges and future proof our long-term strategies.”

While based in Abu Dhabi, the ADNOC Group has operations around the world. As we learned, the company’s comprehensive digital transformation journey encompasses both its upstream and downstream operations. To this end, it is exploring opportunities to employ artificial intelligence and other advanced digital technologies to develop both the digital oilfield of the future and the digital refinery of the future. These efforts extend across the entire oil & gas value chain, including:

- Unlocking new opportunities in subsurface operations

- Optimizing production capacity

- Comparing historical and real-time data to enhance drilling performance

- Monitoring delivery against production targets

- Linking subsurface and surface operations

- Matching processing and refining output with customer demand

- Managing inventories, procurement, and product delivery

- Tracking cargo deliveries around the world

- Visualizing manpower planning and tracking and monitoring health, safety & environment (HSE) performance

Gateway to Digital Transformation

Mr. Nelson then introduced what the company refers to as its “gateway” to digital transformation – the Panorama digital command center. This immense video wall provides a single source of accurate and timely operations and business information across ADNOC’s entire value chain from a secure physical center. If needed, it can also serve as an effective central crisis response center. During the current COVID pandemic, he explained how Panorama has emerged as the backbone for the company’s business continuity efforts.

According to Mr. Nelson, “Panorama puts Big Data at the fingertips of the company’s sharpest minds.” It provides unique visibility across ADNOC’s entire business to enhance decision support and is a key enabler to ensure business continuity during the pandemic by providing real-time COVID tracking and reporting. This helps protect the company’s employees and contractors alike. Using AI, it also helps ADNOC predict COVID impacts and further minimize transmission of the virus across the company.

Lessons from the Pandemic

Commenting on the importance of digital transformation today, Mr. Nelson said, “COVID-19 has taught the industry important lessons. To enable the massive step change in global development, our industry must think differently, embrace disruption, and harness the power of digital and AI solutions.” To this end, ADNOC is bringing together people, data, and technology to help deliver the company’s strategy. Mr. Nelson concluded his Forum keynote presentation by sharing some of his personal observations for a post-COVID world:

- Technology strategy cannot be considered in isolation. It must be developed alongside global strategic partners.

- Companies should support and encourage R&D with partners and ecosystems that have the capability to innovate at scale to reduce the risk of technology commercialization.

- Focus technology strategy and investments on a few impactful platforms. Examples include new energy technologies and manufacturing processes and materials of the future.

- Develop skills that help move science from the lab environment into manufacturing and support the free movement of highly qualified talent.

- Design a procurement and trade policy that not only supports technology but provides a mechanism to support industrial and governmental partners.

These observations line up will with those of ARC’s own analysts.

Q&A Follows

Q&A Follows

In the brief Q&A session that followed these Forum keynotes, Mr. Clausi responded to questions submitted by Forum attendees about open process automation, and Mr. Nelson responded to questions about ADNOC’s implementation of its data-driven digital command center. Craig Hayman, CEO of AVEVA, which has worked with both ExxonMobil and ADNOC in the past and has grown into what is arguably the world’s largest independent software company, also shared some relevant insights from the technology suppliers’ perspective.

Most industrial companies still tend to make decisions based on habitual ways of doing things, tribal knowledge, rules-of-thumb, and the opinions of in-house experts. But leading companies are moving to an information-driven culture and business model in which all decisions are made based on analysis of operations and business process data. Throughout the organization, these companies employ software to collect, contextualize, visualize, and analyze data to gain new insights. The common question is, “What does the data tell us?” Armed with new insights, organizations can anticipate changes and drive better business results.

It is clear that the use of analytics in industrial companies is growing rapidly. With the industrial space becoming much more dynamic, manufacturers are turning to advanced analytics and machine learning to support predictive and prescriptive solutions. More companies are pursuing analytics solutions and more employees throughout the enterprise want more and better decision tools. And the increasing focus on Smart Manufacturing, Industrie 4.0 (I4.0), and Industrial Internet of Things (IIoT) is driving demand for predictive maintenance and operating performance improvement solutions, which rely on advanced analytics.

This program will:

- Cut through the confusion surrounding 'analytics' in the industrial space

- Provide a useful conceptual framework for differentiating modern analytics platforms from previous approaches

- Highlight new technologies, platforms, architectures, and processes

- Present case studies and examples from early adopters of new analytics systems

- Provide industrial companies the information they need to begin their own analytics journey

Most industrial companies still tend to make decisions based on habitual ways of doing things, tribal knowledge, rules-of-thumb, and the opinions of in-house experts. But leading companies are moving to an information-driven culture and business model in which all decisions are made based on analysis of operations and business process data. Throughout the organization, these companies employ software to collect, contextualize, visualize, and analyze data to gain new insights. The common question is, “What does the data tell us?” Armed with new insights, organizations can anticipate changes and drive better business results.

It is clear that the use of analytics in industrial companies is growing rapidly. With the industrial space becoming much more dynamic, manufacturers are turning to advanced analytics and machine learning to support predictive and prescriptive solutions. More companies are pursuing analytics solutions and more employees throughout the enterprise want more and better decision tools. And the increasing focus on Smart Manufacturing, Industrie 4.0 (I4.0), and Industrial Internet of Things (IIoT) is driving demand for predictive maintenance and operating performance improvement solutions, which rely on advanced analytics.

This program will:

- Cut through the confusion surrounding 'analytics' in the industrial space

- Provide a useful conceptual framework for differentiating modern analytics platforms from previous approaches

- Highlight new technologies, platforms, architectures, and processes

- Present case studies and examples from early adopters of new analytics systems

- Provide industrial companies the information they need to begin their own analytics journey

Asset Performance Management incorporates Industrial IoT (IIoT) and new analytics solutions like machine learning. It uses information from production management, control systems, and asset management applications to provide new opportunities to optimize asset availability and operational performance. This optimization goes beyond functional silos and occurs between silos where significant inefficiency, waste, and sometimes dysfunction often reside.

Balancing the objectives of operations for on-time delivery, volume, and quality with those of maintenance for asset availability, longevity, and reliability requires sharing information and harmonizing these objectives with the goals of the enterprise. New information technologies provide functionality to intensify cross-functional collaboration, business process improvements, and higher levels of performance to achieve asset performance management excellence.

The ability to interact with equipment – like a variety of devices on a single site, or widely dispersed machines – presents new opportunities for industrial companies, utilities, and equipment suppliers. These networks provide a new “connected ecosystem” of equipment manufacturers, systems integrators, and end users. Some manufacturers and utilities have begun adopting these technologies.

Those attending this Asset Performance Management program will learn what was successful, and gain insights into what is next. The objective is to make fact-based decisions using reliable information that aligns with the organization’s objectives. An APM strategy helps ensure the best possible returns on capital investments over the lifecycle of the asset. If you are involved in operations, maintenance, or industrial IT, you will want to attend these program sessions.

We have entered a period of intense innovation in industrial automation. In the areas of high value-added manufacturing there is growing global competition. Countries with developed economies want to maintain and grow their existing competitive advantages and support their exporting industries. Countries with developing economies want to improve their competitiveness as well.

This competition is, in part, taking the form of national initiatives to improve manufacturing competitiveness. These initiatives are found in Germany, the US, Japan, Korea, and China. In the US the Industrial Internet Consortium has formed. Platform Industrie 4.0 is the German initiative; the “4.0” referring to a 4th industrial revolution (following steam, mass production, and IT). This can be thought of as a set of new technologies that are fusing the physical, digital, and biological worlds, and impacting all disciplines, economies and industries.

Some of the topics that will be covered in the sessions for this program include:

Devices that will use the future 2‐wire Ethernet standard now in development by the IEEE 802.3cg committee. This 2019 standard will enable high speed communication to process field devices over distances as long as 1 kM.

The Open Process Automation Forum: The Latest Update

The Open Group’s Open Process Automation Forum is noteworthy for several reasons. First, because of its genesis within ExxonMobil, a leading international oil company with a long reputation for operational excellence. Second, because the products of this program will be technologically quite different from the process automation systems used today. Third, because the value chain envisioned for this program is also quite different from the way the process automation market works today. The latest developments in this initiative will be presented and discussed.

Industrial Automation and the Industrie 4.0/Industrial Internet Initiatives

What will be the impact on manufacturing and automation of these major national initiatives? How will the process industries, discrete manufacturers, and automation suppliers adapt and change their products in response to these programs? What are thought leaders in Europe and North America doing now and planning for the next few years? End users will present the current programs for rapid integration of skid-mounted process systems, based on the Module Type Package (MTP) initiative of the NAMUR group in Europe. Also, European end users will discuss their pilot work with the future 2‐wire “single pair Ethernet” standard now in development by the IEEE 802.3cg committee. This 2019 standard will enable high speed communication to process field devices over distances as long as 1 kM.

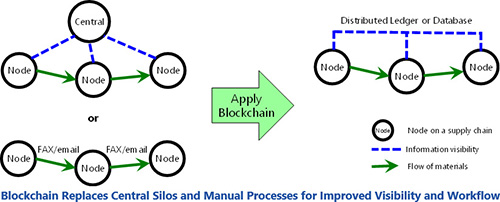

Industrial applications for blockchain technology have emerged for sharing immutable data to reduce costs and grow revenue. ARC Advisory Group has identified and reviewed 28 different industrial applications globally involving proof of concept trials and pilot consortia. The primary objective and the associated portion of the consortia focused on that objective are:

- Automated document sharing to replace email, fax, and phone calls with fewer errors and increased speed and lower cost of trade transactions – 29%

- Improving supply chain visibility particularly for recalls in food & beverage or reverse logistics in pharmaceutical to reduce costs and avoid the negative impact on revenue – 25%

- Trust selling that verifies the commodity’s origin for increased price, margin, and revenue – 25%

A new type of blockchain – private and permissioned – has recently been developed to overcome the transaction delays encountered with the version used for Bitcoin and other cryptocurrencies. This relatively new development has enabled applications in industry.

Blockchain technology has proven to provide clear business benefits for organizations involved in:

- Trade transactions

- Supply chain execution

- Ethically sourced minerals

- Counterfeit parts identification and prevention

Those involved in the aerospace, automotive, chemical, food & beverage, logistics, mining, oil & gas, pharmaceutical, and power industries will find this blockchain program insightful and beneficial.

Industrial cybersecurity is in a state of flux. Ransomware and sophisticated nation-state attacks are undermining confidence in conventional cybersecurity programs. Developments like remote workers, cloud apps, edge computing, and digital transformation are transforming the very nature of industrial IT and OT. Lack of comprehensive, end-to-end security strategies are overwhelming defenders with whack-a-mole efforts to address the growing number of threats. This situation is jeopardizing worker safety and the delivery of critical services in industrial plants, infrastructure systems, and smart cities.

Segregating cybersecurity responsibilities by technology, like IT and OT, is untenable in today’s world. Different people, processes, and technologies create opportunities for attackers to compromise perimeters and enter connected systems. Organizations need programs that monitor, control, and coordinate the security of every corporate device, application, system, and network connection regardless of where it is located — in the IT data center, OT system, Cloud, Mobile, or IoT device. Developing an effective, integrated, comprehensive cybersecurity strategy has never been more urgent.

The Cybersecurity program at the ARC Forum addresses these issues with informative workshops, panel discussions, and case study presentations. It is the ideal venue to learn what others are doing, how they are doing it, and the benefits they are achieving. Attendees will also have opportunities to discuss their unique challenges with peers, researchers, educators, service providers, and solution providers.

The Cybersecurity program at the ARC Forum addresses these issues with informative workshops, panel discussions, and case study presentations. It is the ideal venue to learn what others are doing, how they are doing it, and the benefits they are achieving. Attendees will also have opportunities to discuss their unique challenges with peers, researchers, educators, service providers, and solution providers.

ARC's Cybersecurity program is unique. Other cybersecurity conferences focus exclusively on the issues and technical concerns that frustrate security practitioners. This is important and is addressed in the ARC program, but it lacks context managers’ need to develop strategies for emerging challenges, like digital transformation. Embedded within a conference that discusses the full spectrum of changes occurring in industry, infrastructure, and smart cities, ARC’s Cybersecurity program provides attendees the chance to learn about the emerging business strategies and technologies that are fueling the new normal and creating tomorrow’s cybersecurity challenges. This information is essential for every manager with responsibility for critical decisions about their organization’s current and future cybersecurity programs.

Leaders and decisionmakers in IT, automation, operations, product development, business improvement, and city planning can all benefit from this program. They will gain a solid understanding of the challenges they will be facing, and the actions they can take to avoid crippling cybersecurity incidents.

Autonomy and intelligence embedded pervasively in automation equipment is one of the key attributes to realization of connected smart machinery. Connected smart machinery is important in virtually every application imaginable, but is even more valuable in cases where there is limited communications. Machinery that analyzes and compresses large data sets are essential to ensuring that the data traffic on the Internet does not overwhelm the system or data can be analyzed local to the device. The connected smart machine will require not just more sensors, but also more intelligent sensors. Sensors must perform more sophisticated signal processing “at the edge” to provide accurate signals that filter out the noise before it gets to the automation system.

In this program, machine builders employing intelligent sensors into the machinery to perform complex condition monitoring algorithms into automation systems will be highlighted. Key topics for discussion include:

- Creating new maintenance service revenue streams for machine builders

- Development of equipment protection algorithms that increase resilience of machinery to stay operational for much longer periods of time.

- Adaptive control algorithms allowing systems to operate over a wider range.

- Predictive condition monitoring systems that use real-time control algorithms to provide a new level of maintenance information.

- Exploring the potential of the Industrial Internet of Things (IIoT) to combine the benefits of multivariate analysis, predictive modeling, and inferential information to preempt abnormal situations.

The digital transformation of industry, infrastructure, and cities is under way, with new business processes, services, and models being pursued. This energy and investment is a rational response by organizations to digital economies that present new and very real opportunities. When combined appropriately, data and technology can provide competitive advantage, that – in some cases – enables organizations to leapfrog their peers.

Yet, when planning or executing this transformation, what is often missing is a focus on the human element of digital transformation. Where do people fit in? The changes that digital transformation will have on the workforce are likely to be the most far-reaching and sustained effects. Not only will digital transformation change the number of people needed to do work, it will rewrite how that work gets. Those going through digital transformation quickly realize that managing the human element can be the most difficult aspect. However, as they work through their journey, people begin to better understand the human-centric benefits of digital transformation. Enabled by technology, the workforce will become more empowered to identify challenges, adapt to circumstances, and find new ways to solve problems.

This program will:

- Discuss digital transformation through the lens of people, examining the changes in the workforce as organizations become increasingly data-enabled and service-based.

- Identify the common human-centered challenges to successful digital transformation.

- Provide a framework for creating an organizational strategy and culture for digital change

- Present case studies of how companies organized people and work cultures around digital-first thinking

- Outline how to evolve customer relationships and engagement for a digital world

Industrial Internet platforms are emerging as pivotal, value-added components of the Industrial Internet of Things (IIoT) architecture. These platforms add incremental value by functioning not only as the glue linking connected industrial devices to higher level performance-enhancing applications, but also as the execution environment for the applications themselves.

Industrial Internet platforms play an integral role in analytics, big data, remote asset monitoring, performance management, decision support, universal visualization, and the value chains for connected products and products-as-a-service. The ability of these applications to access, analyze, and process industrial data is central to the IIoT value proposition.

Industrial Internet platforms play an integral role in analytics, big data, remote asset monitoring, performance management, decision support, universal visualization, and the value chains for connected products and products-as-a-service. The ability of these applications to access, analyze, and process industrial data is central to the IIoT value proposition.

Industrial Internet platforms architecturally reside between intelligent devices and higher levels of the enterprise architecture. Device connectivity platforms monitor, collect, process, and transmit data from a variety of intelligent sensors, devices, machines, products, and other assets to higher levels of the architecture, while analytics, big data, machine learning, and numerous other applications that deliver incremental process improvements typically reside in enterprise-level platforms.

The IoT network edge has emerged as a primary vehicle for delivering incremental business value via internet-enabled business strategies such as the Industrial Internet of Things (IIoT), Industrie 4.0 (I4.0), and Smart Cities and Infrastructure.

Escalating demands to feed information from data-rich intelligent edge devices to the cloud is one of the most pressing issues facing OT and IT professionals in the era of internet-enabled business strategies. Standard options include support of common API or protocols, but cloud-based agents themselves are migrating into network edge devices. These agents are increasingly viewed as not only vehicles for closer edge-to-cloud integration, but also as platforms for edge computing applications that execute locally, offloading processing from the cloud and providing enhanced security and closer to real time performance.

This program will highlight current and prospective demands on both network edge infrastructure, such as gateways, routers, and switches, as well as smart end devices that function as edge nodes in the IoT architecture. In addition, this program will look at the central role of Industrial Internet platforms in the emerging Industrial Internet of Things and how to use them to achieve incremental business benefit.

Agenda at a Glance

All times are Eastern Time. For complete session details, please view the Forum Agenda.

Monday, February 8 - Pre-Forum Workshops

| 10:00 AM | Workshop Sessions |

| 12:00 PM | Workshop Sessions |

| 3:00 PM | Workshop Sessions |

Tuesday, February 9

| 10:00 AM | Keynote Presentation |

| 12:00 PM | Keynote Presentation |

| 3:00 PM | Concurrent Track Sessions |

Wednesday, February 10

| 10:00 AM | Keynote Presentation |

| 12:00 PM | Concurrent Track Sessions |

| 3:00 PM | Concurrent Track Sessions |

Thursday, February 11

| 10:00 AM | Concurrent Track Sessions |

| 12:00 PM | Concurrent Track Sessions |

| 3:00 PM | Concurrent Track Sessions |

Featured Speakers

The following executives are featured speakers at the Forum.

Alan Nelson

Chief Technology Officer

Abu Dhabi National Oil Company (ADNOC)

As a member of The Executive Office, Alan is responsible for leading the Company’s Innovation strategy, Digital and Artificial Intelligence development and deployment, and Corporate Sustainability across the ADNOC group of companies. Prior to joining ADNOC, Alan was the Chief Technology Officer and Chief Executive of New Markets for Johnson Matthey plc. As CTO he was responsible for establishing the Company’s innovation portfolio, leading corporate sustainability and directing global research efforts to develop market-facing solutions. Alan was also an integral member of the Executive Committee, providing leadership to define the Company’s strategic direction, development and future growth. Prior to joining Johnson Matthey, Alan served as Global Engineering Director for semiconductor technologies for The Dow Chemical Company. He also previously served as Global R&D Director for Performance Monomers, Plastics Additives, Dow Energy Materials and Engineering and Process Sciences in Corporate Research and Development.

As a member of The Executive Office, Alan is responsible for leading the Company’s Innovation strategy, Digital and Artificial Intelligence development and deployment, and Corporate Sustainability across the ADNOC group of companies. Prior to joining ADNOC, Alan was the Chief Technology Officer and Chief Executive of New Markets for Johnson Matthey plc. As CTO he was responsible for establishing the Company’s innovation portfolio, leading corporate sustainability and directing global research efforts to develop market-facing solutions. Alan was also an integral member of the Executive Committee, providing leadership to define the Company’s strategic direction, development and future growth. Prior to joining Johnson Matthey, Alan served as Global Engineering Director for semiconductor technologies for The Dow Chemical Company. He also previously served as Global R&D Director for Performance Monomers, Plastics Additives, Dow Energy Materials and Engineering and Process Sciences in Corporate Research and Development.

Dominic Clausi

Vice President of Engineering

Exxonmobil Research and Engineering

Dominic (Nick) oversees a global engineering organization – with offices in Texas, Singapore, Malaysia, Canada, the United Kingdom – that provide engineering support for ExxonMobil refineries and chemical plants worldwide. Nick began his career as a Research Engineer with Exxon Chemical Company in Intermediates Technology at the Baton Rouge Chemical Plant. In 2002, he transferred to Chemicals Headquarters where he held various marketing and supply chain roles in the Intermediates and Basic Chemicals businesses. In 2008, Nick began a series of manufacturing assignments in Chemicals and Refining that included Technical Manager of Beaumont Polyethylene Plant, Operations Department Head at the Baton Rouge Refinery, and Plant Manager of the Baton Rouge Plastics Plant. In 2013 he returned to Houston, where he served as the Global Synergy Engineering Manager in ExxonMobil Research and Engineering, Chemicals New Product Platforms Manager, Vice President of Global Chemical Technology and Senior Vice President of Performance Derivatives before assuming his current position in October of 2019.

Dominic (Nick) oversees a global engineering organization – with offices in Texas, Singapore, Malaysia, Canada, the United Kingdom – that provide engineering support for ExxonMobil refineries and chemical plants worldwide. Nick began his career as a Research Engineer with Exxon Chemical Company in Intermediates Technology at the Baton Rouge Chemical Plant. In 2002, he transferred to Chemicals Headquarters where he held various marketing and supply chain roles in the Intermediates and Basic Chemicals businesses. In 2008, Nick began a series of manufacturing assignments in Chemicals and Refining that included Technical Manager of Beaumont Polyethylene Plant, Operations Department Head at the Baton Rouge Refinery, and Plant Manager of the Baton Rouge Plastics Plant. In 2013 he returned to Houston, where he served as the Global Synergy Engineering Manager in ExxonMobil Research and Engineering, Chemicals New Product Platforms Manager, Vice President of Global Chemical Technology and Senior Vice President of Performance Derivatives before assuming his current position in October of 2019.

Herbert Vander Elst

Sr. Director and Head of Tech, Manufacturing & Supply Chain

GSK Vaccines

Herbert (Bert) currently leads Global IT for GSK Vaccines Manufacturing & Supply and is based in Belgium. His team of product owners, designers and engineers outline the IT strategy, engage with the client teams, help reengineering processes, do solution delivery leveraging various competency centers, and monitor support performance. Prior to this, Bert was leading IT for GSK Vaccines R&D, driving forward solutions around human biological sample management and clinical trial supply, e-Labs, Veeva Vault regulatory and clinical replatforming, infrastructure and data pipelines for next gen sequencing across R&D, QbD digital twin, and PLM to address the IDMP data opportunity. Before joining GSK in 2008, Bert was with IBM-PwC focusing on pharma clients, IT strategy, process engineering, and system implementations.

Herbert (Bert) currently leads Global IT for GSK Vaccines Manufacturing & Supply and is based in Belgium. His team of product owners, designers and engineers outline the IT strategy, engage with the client teams, help reengineering processes, do solution delivery leveraging various competency centers, and monitor support performance. Prior to this, Bert was leading IT for GSK Vaccines R&D, driving forward solutions around human biological sample management and clinical trial supply, e-Labs, Veeva Vault regulatory and clinical replatforming, infrastructure and data pipelines for next gen sequencing across R&D, QbD digital twin, and PLM to address the IDMP data opportunity. Before joining GSK in 2008, Bert was with IBM-PwC focusing on pharma clients, IT strategy, process engineering, and system implementations.

Michael Carroll

Vice President of Innovation

Georgia-Pacific

With dog-years of experience as an industry executive, Mike’s background includes pulp and paper with Mead and Georgia-Pacific (GP), robotics and software as Deputy Chairman and CEO of UK based Shepard Ltd., and construction and building products as co-owner of Atlanta based McTech Group, a company serving fortune 500 companies including Walmart, Lowes, Home Depot, Kroger, and others. In 2010, Mike left retirement to join GP as VP Innovation, where the MBM® philosophy and Mike’s mindset of innovation were in alignment. In 2019, he was named Innovator of the Year by ASPI, the Association of Suppliers to the Paper Industry. He also received the 2020 Visionary of the Year award from Smart Industry Magazine. He is involved in numerous innovations and transformations across GP and Koch Industries, and continues to be a frequent featured keynote speaker at industrial and manufacturing events around the world. He is recognized for his knowledge and experience in leadership, innovation, organizational transformation, and intellectual honesty.

With dog-years of experience as an industry executive, Mike’s background includes pulp and paper with Mead and Georgia-Pacific (GP), robotics and software as Deputy Chairman and CEO of UK based Shepard Ltd., and construction and building products as co-owner of Atlanta based McTech Group, a company serving fortune 500 companies including Walmart, Lowes, Home Depot, Kroger, and others. In 2010, Mike left retirement to join GP as VP Innovation, where the MBM® philosophy and Mike’s mindset of innovation were in alignment. In 2019, he was named Innovator of the Year by ASPI, the Association of Suppliers to the Paper Industry. He also received the 2020 Visionary of the Year award from Smart Industry Magazine. He is involved in numerous innovations and transformations across GP and Koch Industries, and continues to be a frequent featured keynote speaker at industrial and manufacturing events around the world. He is recognized for his knowledge and experience in leadership, innovation, organizational transformation, and intellectual honesty.

Andrew Obin

Managing Director

Bank of America Merrill Lynch Equity Research

Andrew is a Managing Director covering the Multi Industry sector. Prior to assuming the Multi Industry coverage in 2012, he covered the Machinery and E&C sectors. Before joining Merrill Lynch in 2002, Andrew worked at Lehman Brothers following the Aerospace and Defense sector. Andrew has consistently been among top ranked analysts in II survey for the electrical equipment and multi-industry sectors as well as his past coverage of machinery and E&C sectors. He has been recognized for the quality of his stock picking and estimates by various industry surveys including Forbes, Financial Times, and the Wall Street Journal.

Andrew is a Managing Director covering the Multi Industry sector. Prior to assuming the Multi Industry coverage in 2012, he covered the Machinery and E&C sectors. Before joining Merrill Lynch in 2002, Andrew worked at Lehman Brothers following the Aerospace and Defense sector. Andrew has consistently been among top ranked analysts in II survey for the electrical equipment and multi-industry sectors as well as his past coverage of machinery and E&C sectors. He has been recognized for the quality of his stock picking and estimates by various industry surveys including Forbes, Financial Times, and the Wall Street Journal.

Adam Peters

Vice President, Electronics World Business Line

Air Liquide

Adam is responsible for business strategy, key customers, product development, and marketing for Air Liquide’s global Electronics business. Additionally, he serves as Chairman of Air Liquide’s Advanced Materials business. Adam began his career with Air Liquide in 1996. He spent nearly 10 years in the Group’s Electronics business, holding various commercial and engineering roles before being appointed Global Account Manager of a major client. In 2006, Adam joined Air Liquide Large Industries U.S. and was appointed Director, On- sites. He was then promoted to Vice President, Large Projects for the same affiliate where he managed the execution of a portfolio of major capital investments. In 2010, he was promoted to Vice President, Operations Control, Americas Zone, overseeing the operations control and strategic planning functions for Air Liquide’s businesses in the Western Hemisphere. Peters relocated to Montreal in 2012 where he was appointed President and Chief Executive Officer of Air Liquide Canada. He served in this capacity prior to rejoining the Electronics team in January 2018.

Adam is responsible for business strategy, key customers, product development, and marketing for Air Liquide’s global Electronics business. Additionally, he serves as Chairman of Air Liquide’s Advanced Materials business. Adam began his career with Air Liquide in 1996. He spent nearly 10 years in the Group’s Electronics business, holding various commercial and engineering roles before being appointed Global Account Manager of a major client. In 2006, Adam joined Air Liquide Large Industries U.S. and was appointed Director, On- sites. He was then promoted to Vice President, Large Projects for the same affiliate where he managed the execution of a portfolio of major capital investments. In 2010, he was promoted to Vice President, Operations Control, Americas Zone, overseeing the operations control and strategic planning functions for Air Liquide’s businesses in the Western Hemisphere. Peters relocated to Montreal in 2012 where he was appointed President and Chief Executive Officer of Air Liquide Canada. He served in this capacity prior to rejoining the Electronics team in January 2018.

Craig Hayman

Chief Executive Officer

AVEVA

Craig joined AVEVA in February 2018 as Chief Executive Officer. Previously he was Chief Operating Officer at PTC where he had responsibility for engineering, marketing, and sales. He also served as President of the Solutions Group. At PTC, he returned the digital engineering business to growth, revitalized the partner network, and successfully introduced a new generation of Industry 4.0 connected manufacturing applications. Prior to joining PTC, he was president of eBay's enterprise business and served more than 15 years in senior leadership positions at IBM.

Craig joined AVEVA in February 2018 as Chief Executive Officer. Previously he was Chief Operating Officer at PTC where he had responsibility for engineering, marketing, and sales. He also served as President of the Solutions Group. At PTC, he returned the digital engineering business to growth, revitalized the partner network, and successfully introduced a new generation of Industry 4.0 connected manufacturing applications. Prior to joining PTC, he was president of eBay's enterprise business and served more than 15 years in senior leadership positions at IBM.

Greg Vigil

Director, Industry Solutions Team

Microsoft

Greg is responsible for Microsoft’s US Manufacturing Industry Executive team where he leads a team focused on engaging with Senior Business Executives to help envision and deliver on digital transformation strategies. The team works with executives to drive digital transformation by re-imaging products in a cloud connected world as well as helping leverage new technologies to transform product development, manufacturing operations, sales and service, with focus on emerging capabilities including the cloud computing, Industrial Internet of Things (IIoT), predictive analytics, AI, machine learning and augmented reality. Prior to joining Microsoft, Greg spent 14 years in a variety of marketing, operations and strategy roles at Gates Corp., the leading manufacturer of belt, hose, and hydraulic products.

Greg is responsible for Microsoft’s US Manufacturing Industry Executive team where he leads a team focused on engaging with Senior Business Executives to help envision and deliver on digital transformation strategies. The team works with executives to drive digital transformation by re-imaging products in a cloud connected world as well as helping leverage new technologies to transform product development, manufacturing operations, sales and service, with focus on emerging capabilities including the cloud computing, Industrial Internet of Things (IIoT), predictive analytics, AI, machine learning and augmented reality. Prior to joining Microsoft, Greg spent 14 years in a variety of marketing, operations and strategy roles at Gates Corp., the leading manufacturer of belt, hose, and hydraulic products.

Eckard Eberle

CEO Process Automation

Siemens

Eckard has been CEO of Process Automation at Siemens AG since October 2014. Previous positions include CEO of Industrial Automation Systems, Head of the Control Components Business Segment, Head of Low Voltage Transformer Business, and Siemens Management Consulting. He began his career at Siemens in 1992 where he was Project Manager for Power Plant Automation, and he established Sales and Engineering in the power plant automation division in Nanjing China.

Eckard has been CEO of Process Automation at Siemens AG since October 2014. Previous positions include CEO of Industrial Automation Systems, Head of the Control Components Business Segment, Head of Low Voltage Transformer Business, and Siemens Management Consulting. He began his career at Siemens in 1992 where he was Project Manager for Power Plant Automation, and he established Sales and Engineering in the power plant automation division in Nanjing China.

Laura Tibodeau

Chief Information Officer

AmSty

Laura was appointed as CIO in July of 2013. Prior to joining AmSty, she worked at Tracor Aerospace, IBM, Texas Instruments, and then Compaq/HP. Laura currently serves as the chairman of the American Chemistry Council (ACC) ChemITC CIO organization, honorary CIO Chairman of the ACC Cyber Security Committee, and Co-Chairman of the governing body of the Houston Evanta CIO forum. She is also on the Board of Directors for Junior Achievement of SouthEast Texas and the Americas SAP Users Group (ASUG) Association. Laura is a licensed professional engineer within the state of Texas and a U.S. patent holder.

Laura was appointed as CIO in July of 2013. Prior to joining AmSty, she worked at Tracor Aerospace, IBM, Texas Instruments, and then Compaq/HP. Laura currently serves as the chairman of the American Chemistry Council (ACC) ChemITC CIO organization, honorary CIO Chairman of the ACC Cyber Security Committee, and Co-Chairman of the governing body of the Houston Evanta CIO forum. She is also on the Board of Directors for Junior Achievement of SouthEast Texas and the Americas SAP Users Group (ASUG) Association. Laura is a licensed professional engineer within the state of Texas and a U.S. patent holder.

It was an honor and pleasure to be invited to speak at the ARC event. I was impressed with the level of knowledge I was exposed to at this conference; this will become an annual event for me. A sincere thank you to ARC for organizing a "WOW" event.

Marty Martin

Director, Process Control Technology

ARC Advisory Group industry events are extremely valuable (to Saudi Aramco). ARC is the barometer for our industry.

Abdullah Al-Khalifah

Senior Engineering Consultant

For me, since I’m from the pharma industry, coming to the ARC forum gives me a chance to interact with folks in like roles from different industries. It’s been very valuable for me to bring ideas and new connections back to my company and apply them to our business.

Kevin Fulton

Director of Engineering

It was a high honor for me to participate [at ARC's Forum] on behalf of the City of Orlando!

Charles Ramdatt

Director, Smart Cities and Special Projects

Previous Attendees

The following companies have attended recent ARC forums:

Air Liquide

Akzo Nobel

Alliance Pipeline

AMEC Natural Resources

Anglo American

Archer Daniels Midland

Axiall

Bahrain Petroleum

BHP Billiton

Blackrock

BorgWarner

Bosch Rexroth

Brady

Cambell Soup

Cenovus Energy

CF Industries

Church & Dwight

Comau

Connacher Oil and Gas

Consumers Energy

CORYS

Cummins

Danaher

Dell

Dominion Energy

DTE Energy

Duke Energy

Eaton

Elkay Manufacturing

EQUATE Petrochemical

Flint Hills Resources

Freeport McMoran

GE

Goodrich Petroleum

Goss International

Greater Cincinnati Water Works

Hirschmann Automation & Control

Independent Belgian Refinery

Inductive Automation

Infosys

International Paper

Iscar Metals

JHP Pharmaceuticals

John Deere

Joy Mining Machinery

Kollmorgen

Kongsberg

KUKA

L&T Infotech

Lafarge

Lockheed Martin

Lopez Foods

LyondellBasell

MESA

MillerCoors

Momentive Specialty Chemicals

Morgan Stanley

Mori Seiki

NAMUR

North West Redwater Partnership

Okuma America

Pacific Northwest National Lab

Palmer Foundry

Panasonic

Panduit

Paper Converting Machine

Parker Hannifin

Patti Engineering

Petro Rabigh

Petrobras

Phoenix Contact

PTC

Public Service Co. of New Mexico

Quiet Logistics

Red Arrow Logistics

Rolls-Royce

Ryder System

Sabic

Sandia National Laboratories

Sekuworks

Shell

Smurfit-Stone Container

Sony Electronics

TetraPak

TOTAL

Toyota Motor Manufacturing

U.S. Department of Energy

Universal Parks & Resorts

Vale

Valero Energy

Vallourec & Mannesmann do Brasil

Walt Disney World

Whirlpool

Wipro Technologies

Xerox

Yanbu National Petrochemical

Yaskawa