The term “digital transformation” has become a buzzword lacking clear meaning. This blog post offers clarification for industrial organizations in an asset performance management (APM) context. Digital transformation is segmented into three categories with case examples of each to provide strategic guidance as to where organizations can focus their programs. These also help provide clarity for communications and avoid obfuscation. The three categories are:

* Business process re-engineering for operations

* New services for existing products

* New business aligned with current domain expertise

A Google search on the term “digital transformation” (with the quotes) gets 12 million hits. The definitions found contain grandiose terms that lack a useful interpretation for industrial enterprises. Wikipedia, which usually has very instructive encyclopedic definitions, also has this difficulty, and ends with a vague statement about “going paperless.” As the Industrial Internet of Things (IIoT) and digital transformation evolved, the term obtained broad meaning and use.

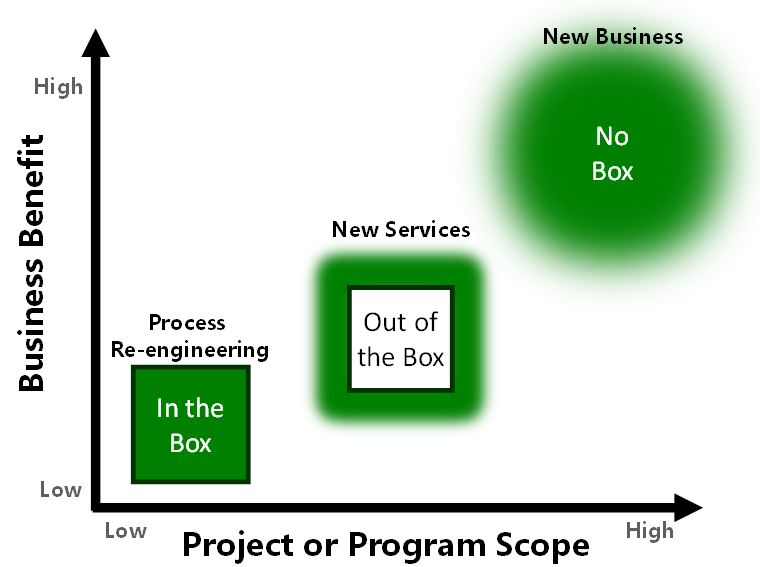

In the diagram positioning the three digital transformation categories shown on this page, the “box” is an analogy for the existing business processes already in place among the people and systems in plants, facilities, or supply chains. The project scope refers to the relative impact on the organization and the degree of executive attention needed.

A few internal departments often work together to re-engineer an “in-the-box” business process, typically with little involvement from senior executives. Here, IIoT is applied to improve and/or augment an existing business process.

Supply chain projects in which IIoT is employed to improve product tracking often fall into this category. Cold chain is an example. Here, a data logger is used to record temperature in the refrigerated trailer. When the shipment arrives, the data logger is checked. If it shows an unacceptably elevated temperature, the shipment may be scrapped, typically leading to a dispute over which group incurs the loss. With IoT and telematics, the temperature can be tracked in real time. When it starts to approach the high limit, action can be taken before damage occurs. Here, IIoT improves an existing (in-the-box) business process by preventing issues, rather than reacting to them “after the fact.”

Unplanned downtime nearly always occurs while an asset is being used. The timing of this type of equipment failure is disruptive to operations, and typically results in lost revenue, missed shipments, and scrapped work-in-process materials. Minimizing this disruption by repairing and bringing the equipment back on-line as quickly as possible is the key reason manufacturers have on-site maintenance technicians.

Industrial equipment OEMs have identified unplanned downtime as an opportunity to employ IIoT to offer new post-sales services. The equipment manufacturer monitors the health of its machine remotely via the internet. The OEM that designed the equipment is in the best position to develop analytics to predict a failure far enough in advance that a repair can be made during a planned outage and prior to failure. When a problem is identified, depending on the type of service agreement, the OEM either sends an alert or a technician. These new, IIoT-enabled services can be added to an existing line of business. The program scope involves the business leaders for the associated product line including product development, marketing, sales, and services.

The “no box” implies a new source of revenue for a supplier beyond the scope of the current business. Typically, the new business is a separate set of services aligned with the supplier’s existing product lines and corresponding domain knowledge. The program’s scope can extend across multiple business units serving a common vertical industry.

John Deere’s Agriculture Technology Solutions provides a case example. The company is well known for its agricultural equipment designed to automate various farming tasks. These include tilling, planting, weed control, harvesting, and processing. Traditionally, John Deere focused on designing, manufacturing, and servicing mechanical equipment used for agriculture. It has added the health monitoring and predictive maintenance services mentioned previously under “new services.”

Taking this one step further, John Deere examined the farmer’s business activities and processes throughout the year, including crop planning, planting, cultivation, harvesting, selling, and financing. The company developed and deployed applications that help the farmer manage these activities and processes. Its deep understanding of the business of farming uncovered other commercial opportunities that are independent of any specific supplier’s farming equipment. To exploit these opportunities, the company developed a new software business for agriculture process management using cloud applications sold as software-as-a service (SaaS).

The wide adoption of technologies for IIoT and analytics has enabled digital transformation for the three categories defined in this blog post. Those considering transformative business changes should focus their efforts along one of these three dimensions.

Plant owner-operators should examine existing business processes and look for opportunities for optimization with IIoT and analytics. The lean manufacturing process of kaizen events and value stream mapping provides a methodology for this kind of review and targeting.

Unplanned downtime disrupts production causing lost revenue, safety incidents, and more. OEMs should consider predictive maintenance services for their equipment using IIoT and analytics to help owner operators avoid these problems and improve customer satisfaction.

For a particular vertical industry, examine your customers’ business processes and look for opportunities to offer applications to improve their business process management. Develop and extend this software business to include owner-operators using your products and those of your competitors.

Digital transformation has many interpretations. If you have categories beyond those in this blog post, the author would like to hear from you.

To learn what your peer organizations are doing in this area and participate in the discussion about digital transformation; asset performance management; and other IIoT-enabled solutions for industry, infrastructure, and smart cities, ARC invites you to join us at our upcoming ARC Industry Forum in Orlando, Florida, Feb. 11-15, 2018.