Representative End User Clients

Representative Automation Clients

Representative Software Clients

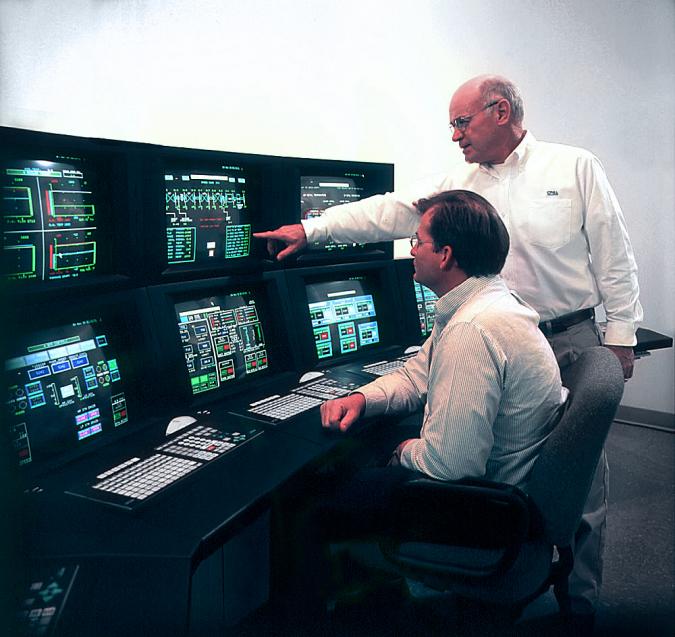

simulators better? Console operators learn best with simulators because the operator remembers best with hands on the mouse and keyboard to address a specific situation. Like learning to ride a bike you just need to get out and feel how it works with some risk of crashing. On-the-job training cannot easily present the operator with all the situations that need to be dealt with. Console or control room operators can regulate very complex and dangerous processes and may have 80 to 150 control loops to keep track of. A visit to a control room with normal plant operation may look rather tranquil. Advanced controls may keep production stable and efficient. That calm can transition to near pandemonium when things go wrong and critical decisions need to be made. Operators will be stressed when they encounter situations they have not seen before. Simulator training should make sure the operator knows how to start all equipment, switch to backup equipment, shutdown equipment, and deal with a number of abnormal situations that have been selected for the training program. Not every accident situation can be trained for, but we know accidents occur often during maintenance, start-ups, and shutdowns. Training for power failures and other critical equipment failures may be a part of the simulation training program. The engineers who design controls, displays, and configure alarms often make complex behaviors and operators do not always know how they work. Having visited many control rooms ARC has observed that operators often have a partial understanding of the control system and tend to use functions they are sure of and are hesitant to explore functions they don't use often. This is where an operator training system proves it's worth. Operators can learn the whole control system, including functions they use infrequently. The additional benefit of simulator training is the operator tests the control system function in realistic situations and often finds errors that were not uncovered during the control system testing. With control system suppliers providing virtual controllers it is easier than ever to build training simulators for both greenfield and brownfield facilities. ARC suggests you take a look at what is available for training simulators with the recent release of the Operator Training Simulation Market Study or the associated Technology and Supplier Selection Guide. In the next blog post we'll explore how virtual reality technology is finding a place in training field operators.

simulators better? Console operators learn best with simulators because the operator remembers best with hands on the mouse and keyboard to address a specific situation. Like learning to ride a bike you just need to get out and feel how it works with some risk of crashing. On-the-job training cannot easily present the operator with all the situations that need to be dealt with. Console or control room operators can regulate very complex and dangerous processes and may have 80 to 150 control loops to keep track of. A visit to a control room with normal plant operation may look rather tranquil. Advanced controls may keep production stable and efficient. That calm can transition to near pandemonium when things go wrong and critical decisions need to be made. Operators will be stressed when they encounter situations they have not seen before. Simulator training should make sure the operator knows how to start all equipment, switch to backup equipment, shutdown equipment, and deal with a number of abnormal situations that have been selected for the training program. Not every accident situation can be trained for, but we know accidents occur often during maintenance, start-ups, and shutdowns. Training for power failures and other critical equipment failures may be a part of the simulation training program. The engineers who design controls, displays, and configure alarms often make complex behaviors and operators do not always know how they work. Having visited many control rooms ARC has observed that operators often have a partial understanding of the control system and tend to use functions they are sure of and are hesitant to explore functions they don't use often. This is where an operator training system proves it's worth. Operators can learn the whole control system, including functions they use infrequently. The additional benefit of simulator training is the operator tests the control system function in realistic situations and often finds errors that were not uncovered during the control system testing. With control system suppliers providing virtual controllers it is easier than ever to build training simulators for both greenfield and brownfield facilities. ARC suggests you take a look at what is available for training simulators with the recent release of the Operator Training Simulation Market Study or the associated Technology and Supplier Selection Guide. In the next blog post we'll explore how virtual reality technology is finding a place in training field operators.