Siemens PLM, a business unit of the Siemens Digital Factory group, recently held their annual analyst conference. There was a very noticeable and very significant difference between the 2018 analyst event and those in past years. Up until now, these industry analyst events provided Siemens PLM an opportunity to present the analyst community with a look at new features, improvements, and new products added to their overall PLM solution portfolio that were developed and released during the last year. In addition, we were presented with a look at new products, solutions, and strategies around the various industries that they served with their technology and products.

What we saw at this recent conference was a complete departure from previous agendas. Siemens PLM, and moreover, Siemens Digital Factory group wanted to show the analysts just how well they had executed on a single theme and present a vision for the future based on this single theme: The Digital Twin. In previous analyst conferences Siemens PLM and its parent business unit focused on the concept of Digitalization, or the notion of the enterprise lifecycle of product design, manufacture, and support. This was the beginning of the overall concept of the digital enterprise connected by the digital thread of virtual engineering design, virtual manufacturing, extending across the virtual supply chain. What we are seeing now with the next generation Siemens PLM solution sets is the realization of the digital enterprise with a new set of transformational solutions that truly define this evolution of the digital enterprise. The concept of the digital twin from Siemens perspective is the complete integration of technologies and solutions that enable this implementation across the entire digital enterprise.

Tony Hemmelgarn, CEO of Siemens PLM characterized all of this as the age of ubiquitous innovation where the traditional boundaries between systems is disappearing, and new solutions are forming that re-define the more transformational and digital relationships between product design, manufacturing, and the virtual simulation that captures and emulates the physical world. Hemmelgarn pointed out how the traditional systems of CAD, CAM, CAE, MES, HMI, EDA, and even PLM, and the boundaries that separated them are dissolving away into the integration of these systems into the digital thread. These new digital systems are represented by emerging technologies and transformative solutions like generative engineering design, additive manufacturing, closed-loop digital twin, electronic/electric integration, the digital factory, autonomous transportation electrification, IIoT and the intelligent edge, and the ubiquitous cloud.

Hemmelgarn focused on some of the key transformational initiatives that Siemens regards as game changers and will have the greatest impact to manufacturing in terms of business value. The relationship between generative engineering design and additive manufacturing processes are having a very significant impact on product design and parts fabrication across industries like automotive and aerospace, and eventually, all industries. Siemens PLM appears to be at the forefront of this transformational process. One example of the industrialization of additive manufacturing was how Siemens Power and Gas 3D prints turbine blades that withstand 1250 degrees, 1000 mph, and 11 tons of force. Another area that Siemens is pursuing aggressively is simulation-based learning for autonomous vehicles and the electrification of transportation in general. Siemens is providing technology and solutions to accelerate the development of autonomous electric cars and is developing an entirely new line of powerful and lightweight electric motors to power a new generation of electric aircraft.

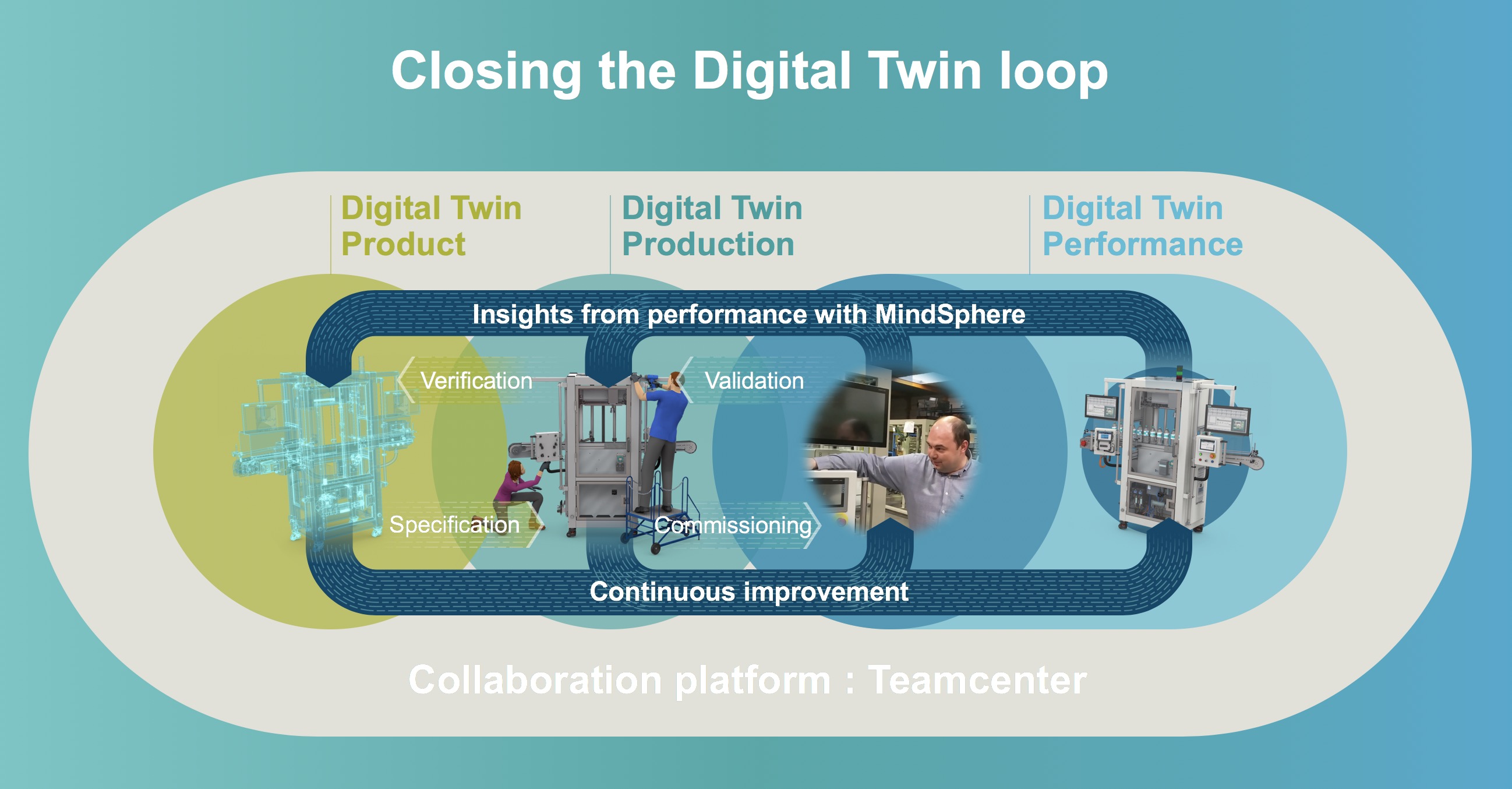

The Digital Factory is one of Siemens strongest initiatives, and one that combines many of Siemens technologies and solutions. Zvi Feuer, SVP for Manufacturing Engineering Software, presented an interesting update on Siemens’ Digital Factory. Feuer pointed out that the top 5 percent of global companies are dominating the economy by exploiting digital competencies. Siemens wants to bring digitalization to manufacturing and democratize innovation to bring the digital factory to all companies. To realize the full value of digitalization Siemens has developed a collaborative platform to implement the digital twin across the design/build/operate/maintain/optimize lifecycle. This platform merges the virtual product design and virtual production process with the real production systems and automation to produce the real product and to deliver it. This platform would include integrated product design and simulation to validate and verify the product prior to production. Virtual production simulation commissions and validates the physical production systems and automation. This extends the use of the digital twin of the virtual and physical domains from product design via production to performance of the systems in a continuous process improvement environment. Siemens Digital Factory involves multiple advanced technologies such as physics-based modeling and simulation, AI and machine learning, virtual and augmented reality (VR/AR), IIoT and intelligent edge sensors, additive manufacturing, and advanced robotics.

Siemens’ Mindsphere, a cloud-based, open, IoT operating system is the platform and backbone that will connect all aspects of the Digital Factory together. However, Mindsphere, as a platform, will support far more than just the Digital Factory. Mindsphere is the IoT and connectivity platform for a range of industries that include Smart Cities and infrastructure, power generation for fossil and alternative energy, process industries, healthcare, mobility, building technologies, energy management, and more. Siemens is building an expansive and global Mindsphere ecosystem of consulting, application developers, connectivity, and technology partners.

Clearly, Siemens PLM will provide the technology and solutions that will drive the overall Siemens Digital Transformation initiative and strategy and will function as the epicenter for all the transformational technologies that will enable their users to realize and implement the concept of the digital twin.