On October 30th, Phoenix Contact hosted a private discussion in Houston with ExxonMobil and ARC Advisory Group. This discussion coincided with the US release of Phoenix Contact’s PLCnext product, an open PLC that supports virtually any software development environment and programming language. ExxonMobil has chosen to integrate PLCnext as one controller in the prototype phase of its own internal open process

Participating from ExxonMobil were Don Bartusiak, Chief Engineer for Process Control; and David DeBari, who had led the company’s OPA proof-of-concept work (conducted under a contract with Lockheed Martin, which served as a system integrator). From Phoenix Contact, the participants were Jack Nehlig, President of US operations; and Ira Sharp, Product Marketing Director for automation. ARC’s Harry Forbes moderated the discussion.

Don Bartusiak related ExxonMobil’s quest to move beyond the customary DCS update process and change the nature of process automation systems by making them far more standards-based, open, secure, and interoperable. This led ExxonMobil to work with The Open Group to form the Open Process Automation Forum (OPAF), which now has 91 member companies. OPAF plans to release version 2 of its specifications in January 2020. For its own proof-of-concept and prototype work, ExxonMobil was attracted to use PLCnext Technology as a “distributed control node” (DCN) – a small-footprint component supporting a combination of sensor I/O, compute, and storage capabilities. Phoenix Contact and ExxonMobil eventually agreed to support the second (prototype) phase of the initiative and provide PLCnext as one DCN platform.

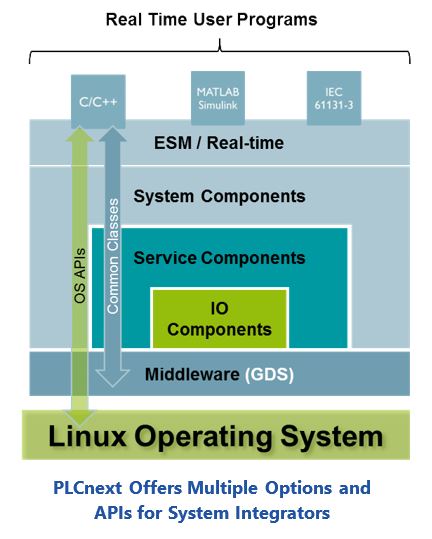

From a hardware standpoint, PLCnext is a typical Phoenix Contact product – compact, rugged, and fully industrial. In the software realm, however, it represents a complete departure. Phoenix Contact provides its

One proof-point of the extreme openness of the platform is that Codesys (a leading independent IEC 61131 software supplier) already supports PLCnext hardware, giving end users a choice of two different software suppliers, even if they limit their software development tools to IEC 61131.

Realizing the completely different nature of PLCnext software compared to conventional industrial controllers, Phoenix Contact explained that it is working to catalyze a developer community for the product. The Yocto kernel code and many other development projects are available on GitHub, facilitating developers who want to use existing code. In addition, Phoenix Contact has created a PLCnext Store website from which both free and commercial software applications can be downloaded.

As the discussion progressed, what struck ARC was that PLCnext very much represents the type of product and business model that the OPAF envisions for the future of industrial automation. Phoenix Contact’s own software competes directly with other commercial products and with “home grown” applications written by

Yet that capability for hardware/software unbundling is exactly what attracts ExxonMobil to employ PLCnext as a small footprint controller in its open automation test lab. PLCnext offers a platform on which system integrators can freely install OPAF-compliant software in addition to other applications. At the same time PLCnext provides high performance interfaces to process I/O. This is exactly the kind of device ExxonMobil envisions as a future distributed control node (DCN).

By working to catalyze a developer community and a software “app store,” Phoenix Contact has launched a product with a business model similar to what OPAF envisions for its members. Contributions to the ecosystem already come from firms that compete directly with some Phoenix Contact products. With both ExxonMobil and Phoenix Contact customers using this new product, PLCnext offers a concrete step on the road to open automation systems. ARC believes the work that system integrators and engineers do with this now-released PLCnext product will be well worth watching.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: ExxonMobil, Linux, Open Process Automation, Phoenix Contact, PLCnext, ARC Advisory Group.