Summary

Several trends – in technologies, user expectations, and improving business benefits – are converging to drive adoption of mobility for asset management. Research indicates that paper-based work order management with manual data entry often leads to a 10 percent error rate for transactions. The resulting data integrity issues negatively impact the ability of the associated system to serve as a useful work management and planning tool. Improved data integrity with a mobility solution for work order management can form the basis for asset management programs that improve the financial measures of a business and its shareholder value. End users should examine their asset management business processes and work flows for the application of mobility solutions.

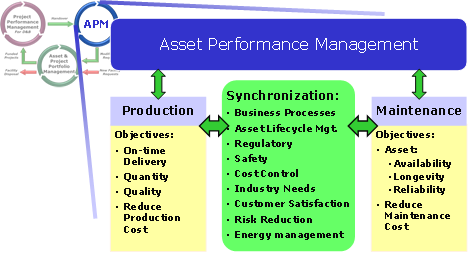

Asset Performance Management

Asset performance management (APM) applies to the long, "operate and maintain" phase of an asset's lifecycle during which revenue, margins, and profits are achieved. An APM strategy involves integrating production management (making the product) with maintenance (ensuring the capability to produce). This enables both production and maintenance management to align and meet objectives with higher productivity, reduced risk, and improved return on assets (ROA).

Optimize Across the Silos

APM includes sharing asset management information with process management applications. This collaboration provides visibility for new opportunities to optimize asset availability. It includes an improved understanding of risk, with fact-based risk assessment. Also, APM enables organizations to uncover opportunities to balance operational constraints and improve ROA.

A range of silos come together in the APM domain, some have traditionally been associated with asset management. These include enterprise asset management (EAM), reliability, condition monitoring, and predictive maintenance (PdM). Others come from production management, including collaborative production management (CPM), laboratory information management systems (LIMS), and control systems (PLC, DCS, HMI). This can extend to include historians and environmental, health & safety (EH&S).

APM Synchronizes Silos across Operations and Maintenance

Visibility

Visibility provides information to improve judgment in real time, when decision-making is most effective. Business activity continues to be increasingly dynamic with changing customer needs, business issues, and priorities – including asset management. To keep up and respond appropriately, managers and technicians need access to current information to maximize the effectiveness of their decisions and speed to results. In ARC Advisory Group's annual user survey on asset management, visibility emerged as an increasingly important need for managing maintenance.

Data Integrity

A key foundation for visibility for faster and better decisions involves dependable data. Data integrity refers to maintaining and assuring the accuracy and consistency of data over its lifecycle. People must trust what the systems tell them so they can use the information with confidence. Since APM involves operations with specific objectives and competitive pressure for high performance, the participants typically have a low tolerance for data quality issues like data inconsistency, incompleteness, ambiguities, duplication, and latency. Poor data results in a loss of confidence in the system, manual workarounds, delays, and lower business performance. Data integrity improves when data is collected in real time as part of the work process.

Business Impact

Good asset management improves the financial measures of a business. High asset performance supports successful financial performance by improving:

Systems – particularly EAM and reliability - are required for managing assets and delivering the desired financial benefits. Effective use of these systems requires data integrity.

Paper Input Equals Errors

Paper-based systems tend to create delay and data entry errors that negatively impact system integrity. When people don't trust the system, they have to do more things manually and create unnecessary workarounds, hampering productivity and increasing waste.

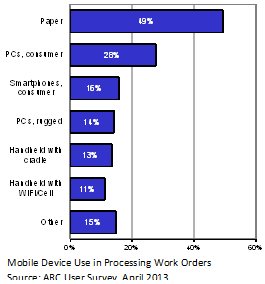

Unfortunately, paper-based manual processes are the most common method for processing work orders. Back when barcode systems were being introduced, a study examined the relationship between handwritten transactions and data entry. It examined the process of filling in a typical handwritten form containing 80 characters and keypunch data entry. The study showed that 10 percent of the transactions contained errors. The sources of error included wrong entries, poor handwriting, and misinterpretation of abbreviations. In companies that use paper for work order processing, the associated systems will have data integrity issues, leading to mistrust of the results. These systems have probably devolved into historical record-keeping system, rather than an effective, proactive planning and management tool.

Unfortunately, paper-based manual processes are the most common method for processing work orders. Back when barcode systems were being introduced, a study examined the relationship between handwritten transactions and data entry. It examined the process of filling in a typical handwritten form containing 80 characters and keypunch data entry. The study showed that 10 percent of the transactions contained errors. The sources of error included wrong entries, poor handwriting, and misinterpretation of abbreviations. In companies that use paper for work order processing, the associated systems will have data integrity issues, leading to mistrust of the results. These systems have probably devolved into historical record-keeping system, rather than an effective, proactive planning and management tool.

Asset Management Needs Mobility

Several asset management applications can benefit from mobility solutions. These include EAM, fleet maintenance, plant asset management (PAM), preventive maintenance, PdM, field service management, and EH&S.

Most Asset Management Personnel Are Mobile

Mobility for asset management applies to maintenance and field service workers whose daily workflow involves going to the equipment's location to perform their assignments. Each assignment has a new location, making stationary workstations impractical. These mobile workers include technicians, craftspeople, dispatchers, maintenance, and other personnel who physically move about the facility or among customers.

Application | Mobility’s Impact |

Plant Equipment Maintenance | Work order execution and equipment uptime for production |

Field Service Management | Routing optimization, customer satisfaction, and up selling |

Fleet Maintenance | Vehicle longevity and availability for on-time deliveries |

PAM and Condition Monitoring | Data collection, accuracy, and display |

Environmental, Health & Safety (EH&S) | Execution and compliance enforcement |

Applications Using Mobility for Asset Management

Mobility solutions provide bi-directional data exchange, including information display, data entry, automated data collection, and access to documentation for work orders while the technician is located at the asset. While mobility software continues to become more functional and easier to use, mobile applications have also grown in capability and now provide value-added utilities that assist a technician during their workflow. The mobile device allows a technician to enter information and process the work order while he or she performs the needed work. This assures automated error checking and improves both data integrity and compliance.

Schneider Electric Wonderware IntelaTrac Solution

As ARC learned during recent briefings, the Schneider Electric Asset Performance Management solutions, Avantis EAM and Avantis Condition Manager, are often deployed with Wonderware IntelaTrac for a mobility solution. According to the company, Wonderware IntelaTrac is the industry-leading mobile workforce and decision support system. IntelaTrac includes configurable software and ruggedized mobile hardware solutions that enable workflow, data collection, and general task management for plant operations, maintenance management, production tracking, and compliance applications. IntelaTrac is platform-independent, enabling it to work with a variety of EAM, inspection, and process control systems.

Conclusion

Nearly all asset management personnel are mobile. With mobility solutions, technicians become more empowered with access to work order information, asset history, spare parts inventory, repair instructions, location, travel directions, maps, and more. In addition, many high-value assets are mobile, including inventory, instruments, custom tools, or even a valve (or other major automation component) that has been removed to be refurbished. Mobility extends asset management business processes to the point of action, creating enormous opportunities to optimize business performance.

End users should examine their asset management business processes and workflows for potential application of mobility solutions. Projects that were not approved in the past should be re-visited. The maturing of mobility solutions has lowered project costs and improved the business benefits.

All signed-in ARC Advisory Group clients can view this report in pdf format at this Link

If you would like to buy this report or obtain information about how to become a client, please Request ARC Info

Keywords: Asset Performance Management, APM, Mobility, Enterprise Asset Management, EAM, Field Service Management, FSM, Plant Asset Management, PAM, Predictive Maintenance, PdM, Environmental Health & Safety, EH&S.