At our ARC European Industry Forum 2018, Chris Hazlewood, Senior Manager at MITSUBISHI ELECTRIC, gave an important Key Note speech about two key technologies forming the digital enterprise; Edge Computing and Artificial Intelligence (AI) but it seems the company has been working in the background on a third: 3D printing.

Recently the company announced that it will introduce a new 3D metal printing technology which they will be showing on the JIMTOF 2018 show in Japan for the first time worldwide.

Even though we were already aware that Mitsubishi Electric is pushing Edge and AI technologies, I was surprised hearing this development. On the one hand Mitsubishi is an automation supplier, with many machinery builders as customers; on the other Mitsubishi itself is a machinery builder, competing with potential automation customers. According to the company, there are three main things that makes this technology special:

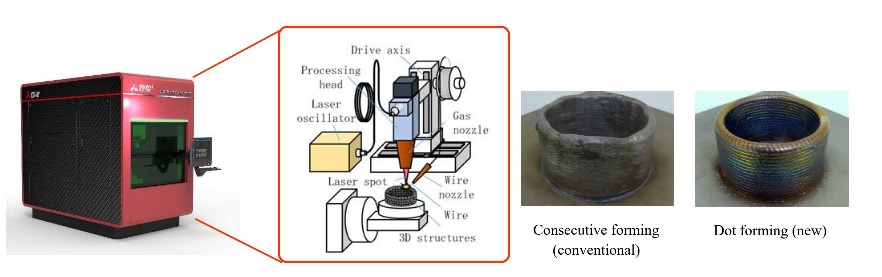

• The "finish" of the final result looks good on the released picture. According to ME the advantages are, that there are few voids in the structure wall and so the amount of secondary processing would be minimal if at all.

• It uses a wire depositing technique rather than a fused metal particle (granular material fused in to form).

• It is almost possible to say that the 3D printers are a small digital factory in themselves with a flow through the processes of structure building and finishing - interesting from the viewpoint of the application of robots, servo motors, CNC and laser.

According to Mitsubishi Electric the technology produces high-quality three-dimensional (3D) parts with few voids at high speed, employing a laser wire directed-energy deposition (DED) method. This additive-manufacturing process uses focused thermal energy to fuse materials as they are deposited. Mitsubishi Electric believes that its new technology will raise productivity in a wide range of applications, such as the “near-net” (near-final) shaping of aircraft and automobile parts and build-up repairs. Mitsubishi Electric expects to launch a commercial version within the fiscal year ending in March 2021.

We here at ARC are curious to see the first machines in real life, maybe at the Hannover fair. Unfortunately it will not be shown at this year’s important trade show on Additive Manufacturing (AM) in November, formnext 2018 in Frankfurt. There we will hopefully see other highlights. ARC will track the fast growing and inter-esting industrial AM market. Look out for more to come on this topic.