Yokogawa participated as a Platinum Sponsor at ARC Advisory Group’s 21st India Forum titled Driving Sustainability, Energy Transition, and Performance through Digitalization on July 12th and 13th, 2023. The 300+ delegates at the Forum networked, shared best practices, and got an overall view of market trends and requirements. In the Forum session on Digital Transformation and Sustainability Initiatives (Part 1), Nitin Soni, Certified Smart Industry Assessor, DX Solutions Consultant, Yokogawa spoke about digital transformation consulting for industries. Yokogawa’s Digital Solution Center located in Bangalore focuses on providing technologies and IT/OT solutions to its customers throughout their digital transformation journey. At the end of the session, Sumit Srivastava, Vice President & Head of Digital Solutions, Yokogawa joined the panel discussion.

This blog captures the salient points of Nitin’s presentation and Sumit’s views; the entire presentation is available right here.

Defining Yokogawa’s goals, Nitin explained that broadly it is about well-being, circular economy, and net zero emissions, and the contribution areas are achieved by IT/OT solutions and technologies that support its customers. Companies that are more advanced in their digital journeys are already integrating sustainability and energy transition initiatives, together with competitive excellence, resilience and agility, and workforce goals into a comprehensive strategy driving towards becoming a focused, integrated, digital organization.

The key pillars for climate change, resilience, and sustainability that lead to smart manufacturing are energy transition, sustainability, and stakeholder engagement. Yokogawa’s solutions help customers tackle climate change in the following ways:

Improve efficiency levels in society and industry.

Optimize plant lifecycle and protect the environment.

Improve health and safety.

Create a resource recycling ecosystem.

Create workplaces where people can fulfil their potential.

Achieve carbon neutrality.

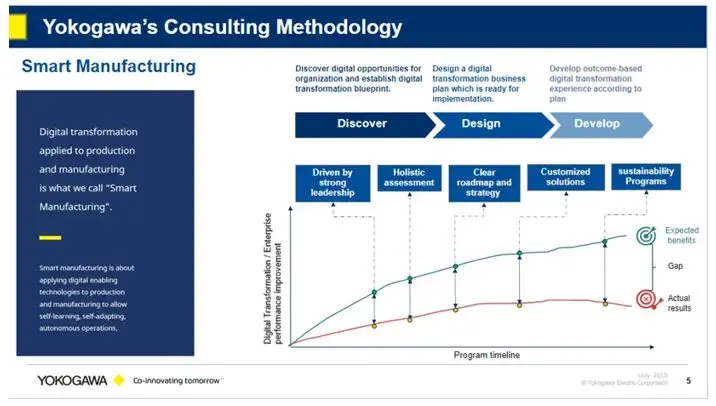

Digital transformation has moved beyond the hype and some industries have realized immense benefits of deploying new technologies and processes. However, industry experience and research reveal that the digital transformation results/benefits are uneven, and the ROIs (return on investments) are below expectation levels. Surveys show that lack of a clear vision, strategy, and a systematic roadmap are the biggest hurdles hindering digital transformation adoption.

Further, Nitin spoke about Yokogawa’s consulting methodology. Digital transformation applied to production and manufacturing is Smart Manufacturing. Yokogawa’s three-phase methodology: discover, design, develop ensures that the gap between the actual versus the expected benefits is reduced and sustainable value is delivered to the customer. Yokogawa’s value proposition:

End-to-end solutions covering the entire value chain.

Integrating best-in-class domain knowledge with over 100 years of industry expertise and production automation solutions.

SIRI (Smart Industry Readiness Index), launched by the Singapore Economic Development Board (EDB) in 2017, comprises a suite of frameworks and tools to help manufacturers to start, scale, and sustain their manufacturing transformation journeys. Nitin explained the assessment matrix that comprises of 16 core elements, prioritization matrix, and performance evaluation and showed a sample assessment report.

Supply Chain Improvement by Horizontal Integration

Challenges: No clear blueprint for transformation to improve supply chain; unable to achieve benefits from siloed digitalization initiative in horizontal integration; and sub-optimal production.

Solution: After detailed assessment and designed implementation plan and deploy solutions (IT/OT convergence and automated workflows) to deliver improved value.

Benefits: Holistic assessment, detailed designed improvement plan, and improved value and visibility.

In today's world, everything is increasingly interconnected in complex ways. According to the system of systems (SoS) concept, multiple independently operating and managed systems coordinate together to achieve a purpose that lies beyond the capabilities of any single system. In such a world, Yokogawa will promote effective connections and create value through overall optimization driven by integration, autonomy, and digitalization. Yokogawa will achieve this through IA2IA (Industrial Automation to Industrial Autonomy) and smart manufacturing and aspire to lead the way forward as an integrator in a world where entire societies function as an SoS.

How can SMEs leverage smart manufacturing technologies and overcome implementation challenges?

Sumit: One of the most important factors is the reason behind implementing smart manufacturing technologies. You have to ask yourself why it needs to be implemented. Various aspects need to be considered. There is the holy trinity of profitability, circularity, and for the wellbeing of society. Profitability provides the impetus to drive this transformation and gain organization-wide acceptance; and when there are regulatory requirements you need to be circular to improve efficiency. Acceptance and ownership is important, so that it is culture driven and sustainable. In a nutshell. be clear about the purpose, select the appropriate technology, orient the plant configuration, and have measurable goals.

How do you see digital transformation consulting?

Sumit: Digital transformation is a very wide subject and can touch all areas of the plant and operations – manufacturing, supply chain, planning, scheduling or sustainability objectives. It covers a wide gamut of aspects and the customers have to prioritize implementation based on the cost and time factors, and implementation benefits. The implementation will require integration, automation, and transformation at the digital level. So there is wide ranging applicability, not just a software layer on top; it is an ecosystem evolution.

Expectation setting and benchmarking.

Sumit: This is crucial and an important aspect of the digital transformation project. There is no perfect way to go about this, it has to be jointly evolved by the customer and supplier. Benchmarking has to be done to establish the current state and expected ROI. There has to be a good measurable mechanism for the benefits to be accrued. Establishment and achievement of the objectives have to be documented, understood, and accepted. Usually the sustainability part of the benefits are missing; this is not a one-time activity, it’s a continuously evolving exercise.