In a recent two-day session at its headquarters, Dassault Systèmes executives provided ARC Advisory Group with new insights into the company's strategy, products, and business dynamics.

Many people associate Dassault Systèmes with designing industrial machines and products. However, it

Companies in these industries face daunting challenges. Increasing environmental awareness and newly available technologies are disrupting traditional business models. Trade wars increase market complexity and price volatility and put downward pressure on profits. Companies must adapt to the dynamic new demands by continuously innovating and by putting systems in place that allow them to change quickly yet still execute effectively and efficiently.

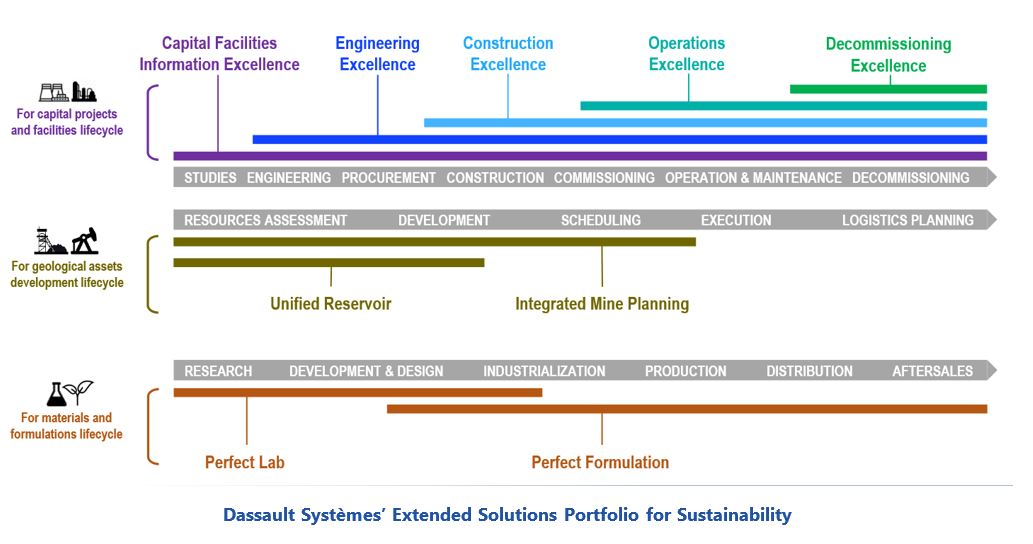

Large capital projects in the power, oil & gas, and chemical industries are inherently complex, involving multiple stages and entities and engendering potentially large risks. According to the company, integrating all associated information using the 3DEXPERIENCE platform can improve results while reducing risks. By integrating the requirements, engineering, and resource and process management functions in the same platform with the required simulation, change management, issue management, and project/program work breakdown structures and task management, continuity can be maintained as the project transitions from study to engineering to construction and commissioning, then to operation and maintenance and eventually decommissioning. Dassault Systèmes has become a recognized player in this space in the last few years.

Geological assets are the beginning of the energy and materials value chain, the source of raw materials that will be used as fuel to power vehicles and cities and as inputs into chemicals and manufactured products. Dassault Systèmes solutions are designed to enable its customers to model, produce, and optimize the value chain execution of mining and oil and gas commodities. To help mitigate economic and safety risks during extraction of geological resources, it also provides the ability to simulate the stability of oil and gas reservoirs and mining locations.

As we learned, the 3DEXPERIENCE Platform and its associated solutions are designed to equip the mining or oil & gas industries for business transformation at the project and asset levels and across the entire ecosystem from extraction to customer delivery, and across the asset lifecycle from exploration to eventual closure and rehabilitation (mining) or decommissioning (oil & gas). With the large degree of uncertainty at the early stages of asset lifecycle and complexity of deposits, market vagaries, macroeconomic and political/geographical considerations to be factored in, the extent to which data integration is managed is one key to optimization and value realization.

Dassault Systèmes’ experience with manufacturing and other industrial applications of both the 3DEXPERIENCE Platform and associated technologies has been well received in industries that have typically been close followers, rather than early adopters.

In the industrial goods sector, customers increasingly demand better performing, more targeted products. To respond, specialty chemicals companies must develop new products rapidly and effectively. To meet customer product performance needs, it is important to integrate virtual simulation into laboratory management systems. Predictive science can be used to custom design better-performing products while reducing physical testing. Modeling and simulation of materials combined with streamlined laboratory operations can improve innovation without increasing overhead. Research teams can work more efficiently, and customer service teams can also respond more nimbly to customer needs.

BIOVIA combines a wide array of capabilities in product design and simulation with a comprehensive digital laboratory management system built on an innovation platform that integrates with portfolio and product lifecycle management solutions. These solutions allow scientists to run complex virtual simulations generating many simulated product configurations. They can model chemical behavior to select products for desired characteristics and use product simulations to minimize or eliminate testing and prototyping.

Dassault Systèmes has a growing footprint in the power, oil & gas, mining, metals & minerals, and chemicals sectors. The company’s focus on nature manifests itself in the breadth of solutions that leverage simulation, design & engineering, and collaboration tools to support capital projects and facilities throughout their lifecycle, geological assets through their development lifecycle, and materials and formulations throughout their lifecycle.

Dassault Systèmes energy and materials customers already use the 3DEXPERIENCE platform for execution transparency of capital projects across multiple offices. They use it to improve the performance and competitiveness of plant engineering projects and for nuclear power. They use it to support engineering data aggregation in upstream, midstream, and downstream facilities. Many customers also use it to optimize all operations, from planning to production.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Dassault Systèmes, 3DEXPERIENCE Platform, Manufacturing, ARC Advisory Group.