The

power of connected is evident everywhere. It is not just about connecting devices and sending data to the Cloud; it is about connecting the right ideas/people; resolving issues before they occur (predictive analytics); safety/cybersecurity – and improving the return on investment (ROI). I believe that this connectivity seamlessly links technologies, processes and skilled people, driving businesses globally. This was the core theme of Honeywell’s first India Technology Summit

Honeywell ITS in New Delhi, which G. Ganapathiraman, Country Manager ARC Advisory Group India recently attended. Honeywell is working towards a connected world by linking the physical and virtual to transform industrial operations – this is the Industrial Internet of Things (IIoT). Through interactions with the attendees (close to 150) and organizers, ARC learned how IIoT is revolutionizing business operations the world over. HCP’s solutions enable manufacturers and process industries leverage data and insights to improve the efficiency and profitability of their operations. The presentations at this event revolved around the core theme of the

power of connected, which is also Honeywell’s tagline, focusing on the key technological trends - Cloud, mobility, Big Data, Analytics, 3D visualization, high fidelity simulation, and cybersecurity.

India is at the cusp of a digital revolution and it is imperative for industry to adopt world-class technologies that improve safety, reliability, and efficiency in an increasingly competitive global environment. According to Steve Gimre, Managing Director, Honeywell UOP India, IIoT is the industrial revolution of the 21

st century and

Make in India is at the heart of Honeywell’s business strategy. The HCP proposition focuses on technologies and industrial solutions to help organizations harness the power of IIoT. For example, to improve operator effectiveness in a refinery, the solutions deployed were: remote operations support, competency building, mobility tools, and alarm management. This improved output by 0.25 percent; in monetary value this translates into $4.8 million.

Other interesting solutions and their implementation were also focal points. The audience were keen on knowing how to reduce CapEx, streamline processes, and improve safety levels. With reference to these the concept of LEAP (Lean Execution of Automation Projects) – a paradigm shift in the way automation projects are executed - was explained in detail. This covers: Universal input/output modules; virtualization; and Cloud engineering. The topic of skills scarcity in every industry always garners my attention. To combat this Honeywell came up with suggestions such as training and practice; industry-academia partnership and so on, which are fundamental to gain skills.

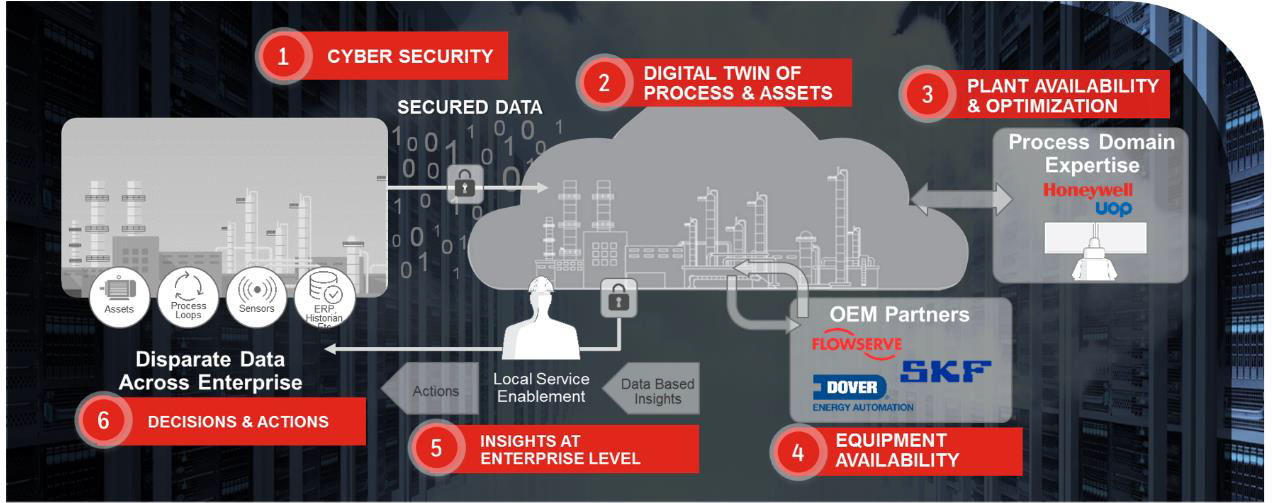

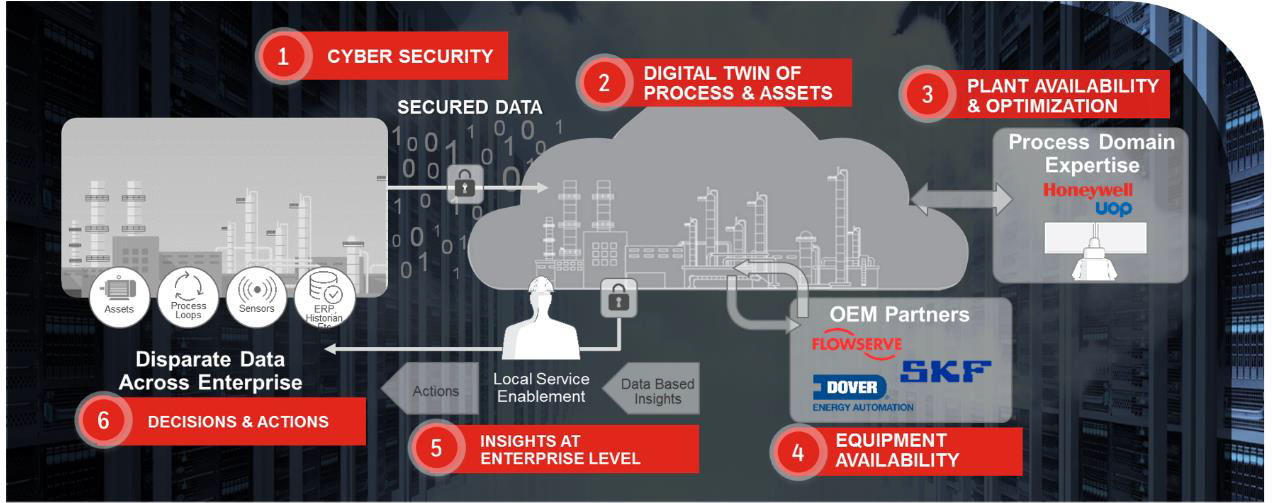

As a natural fallout in a connected world, there was a discussion on the Connected Plant.

The Connected Plant (Honeywell)

Through case studies it was shown how a connected plant reduces total cost of ownership as it provides higher operational flexibility, reduces IT infrastructure cost, and improves uptime. Digital twins occur at the intersection of physical engineering and data science, and their value is measurable: reduced asset downtime, lower maintenance costs, improved plant and factory efficiency, reduced cycle times, and increased productivity.

I believe that technologies that increase connectivity simultaneously increase the risk of cyber-attacks. HPS has a connected Industrial Cybersecurity Risk Manager, which proactively monitors, manages, measures, and reduces the complexity of cybersecurity risk – this has been installed in industries, such as specialty chemicals and refineries. During the panel discussion it was opined that cybersecurity certification must be made mandatory before adoption of IIoT.

Events such as this one reiterate the fact that IIoT is altering traditional ways of doing business and restructuring the landscape. No one asks “should we?” Because they know that they have to. Companies, such as Honeywell are ready to ride the IIoT wave – because they know that the future is already here.