Rockwell Automation participated as a Gold Sponsor at the 2021 online ARC Industry Forum Asia titled Accelerating Digital Transformation in a Post-COVID World.

Samrat Datta, Information Solutions Business Lead, Rockwell Automation, spoke about how the company’s transformation to the Connected Enterprise is helping its customers become more resilient and agile too. He

This blog captures the highlights of Mr. Datta’s presentation. His presentation video (Day 2, Session4) will be available at the vFairs platform for the next three months: ARC Asia Forum 2021 (vfairs.com). The documents and video link are also available at the Rockwell Automation booth.

The disruptions we are seeing today:

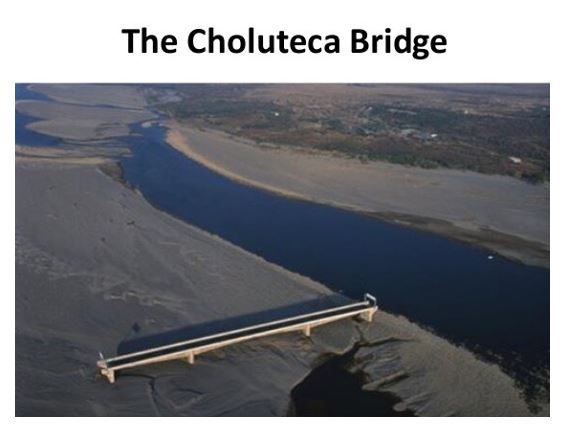

All these requirements lead to greater focus on digitalization and its financial impact. Research done by the World Economic Forum (WEF) shows that double digit improvements are seen when manufacturers deploy digital transformation at scale. However, 75 percent of these projects fail, because they are unable to scale (pilot purgatory).

From a strategic perspective, one of the most prevalent issues is that these pilots are typically technology led rather than value led. As a result, there is a lack of clarity to financial impact and ROI from these pilots, but, there is also an execution perspective. The environments that most companies are working with are complex and heterogenous, which can create implementation complexity for cross site initiatives. Lack of standardization in combination with the above complexity results in varied data connection methods, making information difficult to access and contextualize. Finally, the historical approach to digital transformation initiatives has relied heavily on bespoke implementation. This custom, DIY development slows time-to-value, doesn’t scale and doesn’t upgrade.

Rockwell Automation is a 100-year-old manufacturing entity, with 19 plants across the world. It has multiple product types with 387,000 SKUs (stock keeping units); an average order that Rockwell processes consists of 200 SKUs. Products are sold in highly regulated markets, like pharma and food and beverage, so different production strategies are followed.

Mr. Datta showed the different kinds of products that are manufactured under components, control & visualization platforms, and solutions/ETO (efforts to outcomes) that have different manufacturing complexity and lead times. Hence, when the company started its digital transformation journey it realized that technological bottlenecks had to be addressed, and what was needed was one connected system to take the right data and turn it into value. To get a single version of the truth all systems had to be connected, and this led to the Connected Enterprise. The four major interlinked vectors of value in the Connected Enterprise are: work order control, operator control, process control, and data & system integration.

After the solution was put in place it took two years for Rockwell Automation to scale across all its facilities. Overall productivity increased by 5 percent annually; inventory reduced from 120 to 82 days and lead times by 50 percent; 60 percent reduction in quality rejects; 30 percent reduction in capital avoidance; and time-to-delivery improved from 82 percent to 96 percent. Achieving this kind of outcome required huge amount of change management across three different pillars – people, process and technology.

On the people front Rockwell Automation is continuously upskilling, so every site has digital champions, and every process area has a digital super user. At Rockwell Automation, digital is not a piece of technology, it is a way of thinking, and building it into the organization’s culture. Secondly, business processes were standardized and aligned to Rockwell Automation’s enterprise digital vision. And finally, on the technology front, Rockwell Automation’s platform, FactoryTalk Innovation Suite powered by PTC, helped bring the complete solution to life.

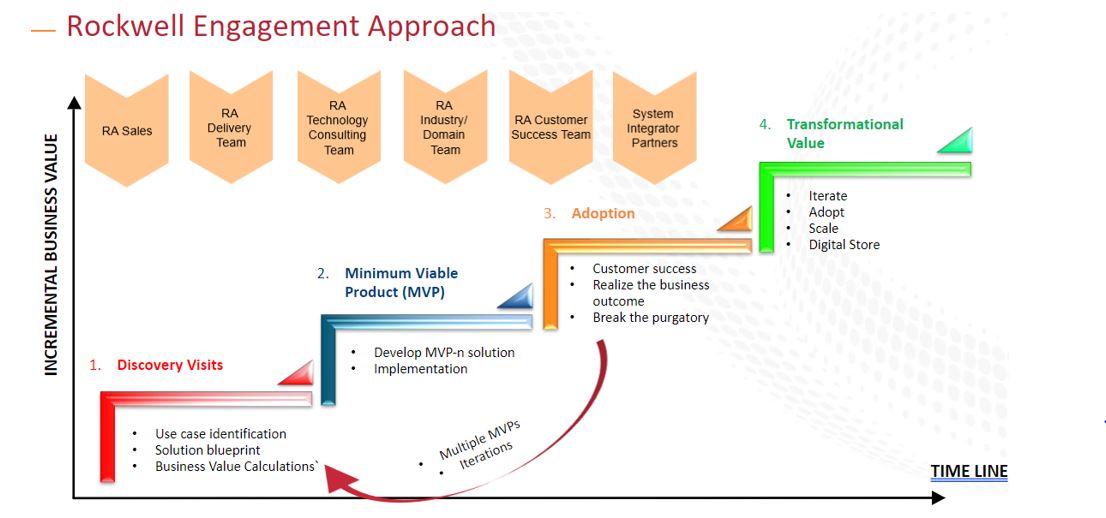

To help customers overcome their business challenges, Rockwell provides incremental business value through four important steps - value workshops, minimum value product (MVP), scale and adopt, and transformational value. This is possible, because inhouse domain experts, partners, and system integrators are walking on this digital transformation journey together. This unique collaborative approach helps customers achieve operational excellence.

National Engineering Industries (NEC), part of the CK Birla Group is India’s leading bearing manufacturer and exporter.

Objective: To convert a brownfield factory into a smart, connected plant using the latest digital technologies.

Outcome: Rockwell Automation’s solutions (FactoryTalk and ThingWorx APM) improved overall equipment effectiveness by 2-3 percent. This solution is being scaled across 3 more sites.

The link to the case study.

Aluminum major in India wanted to break down the silos and democratize data.

Objectives: Improving asset utilization and throughput. Reducing sales return and quality costs.

Outcomes: Reduction in sales rejects – 20-30 percent; improvement in asset utilization – 2-3 percent; and improvement in throughput – 1-2 percent. The solution was scaled across 6 sites. Rockwell is also assisting them to build a command-and-control center.