ARC held its third virtual European Industry Forum on May 17th and 18th. The manufacturing operations  management session at the ARC European Industry Forum 2022 demonstrated once more that the topic is alive and evolving and that users, technology and service providers keep adding depth and experience to the body of knowledge on operations management design, build, deployment, maintenance, and value creation. As part of the Forum, this traditional session on manufacturing operations management was held in cooperation with MESA International.

management session at the ARC European Industry Forum 2022 demonstrated once more that the topic is alive and evolving and that users, technology and service providers keep adding depth and experience to the body of knowledge on operations management design, build, deployment, maintenance, and value creation. As part of the Forum, this traditional session on manufacturing operations management was held in cooperation with MESA International.

MESA gave a keynote about the new MESA Smart Manufacturing Model, linking digital threads of long business processes with those of support processes, asset lifecycles and enabling technologies. Chairman of MESA Europe Uwe Kueppers explained that the model can help companies to implement manufacturing operations management by providing a generally applicable structure so that stakeholders can exchange effectively. It helps them to evaluate solutions, technologies, and offerings, to ultimately determine how well they fit their businesses.

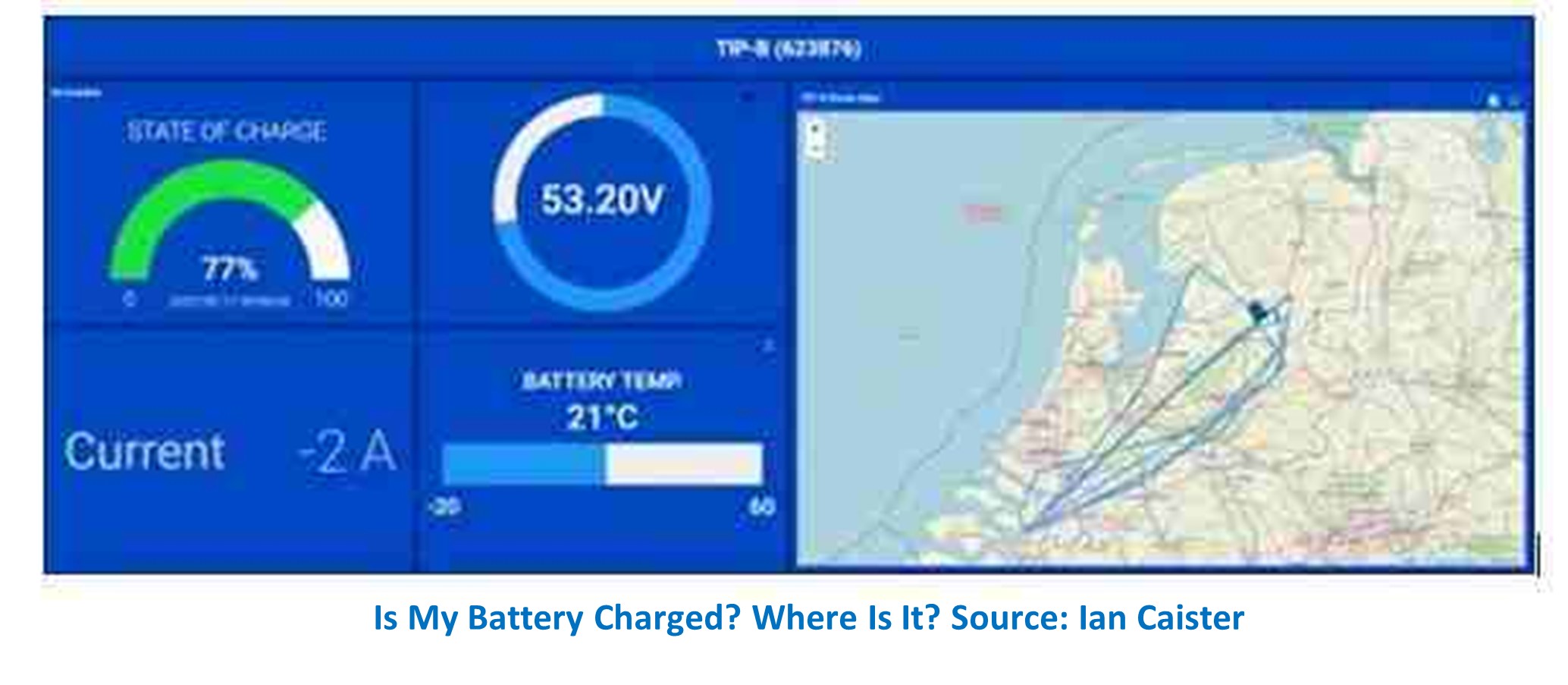

Ian Caister, MESA member and representing his own company, explained how he designs and implements bespoke IIoT solutions for a wide variety of needs combining serverless cloud services with custom edge devices based on proven modular hardware architectures. He proposed some real-world solutions for SMEs, often constrained by budget, IT infrastructure and application knowledge on one hand, and by limited bandwidth, intermittent connectivity, remote or moving assets on the other.

The devices used are combinations of proven components and designs and have a level of standardization at the module level, which explains the controlled cost, scalability of production and device reliability, comparable with mass customization of consumer products. Combined with ThyssenKrupp Material IoT’s solutions for small, poorly instrumented and automated industrial sites, this makes for a full smart manufacturing strategy for SMEs

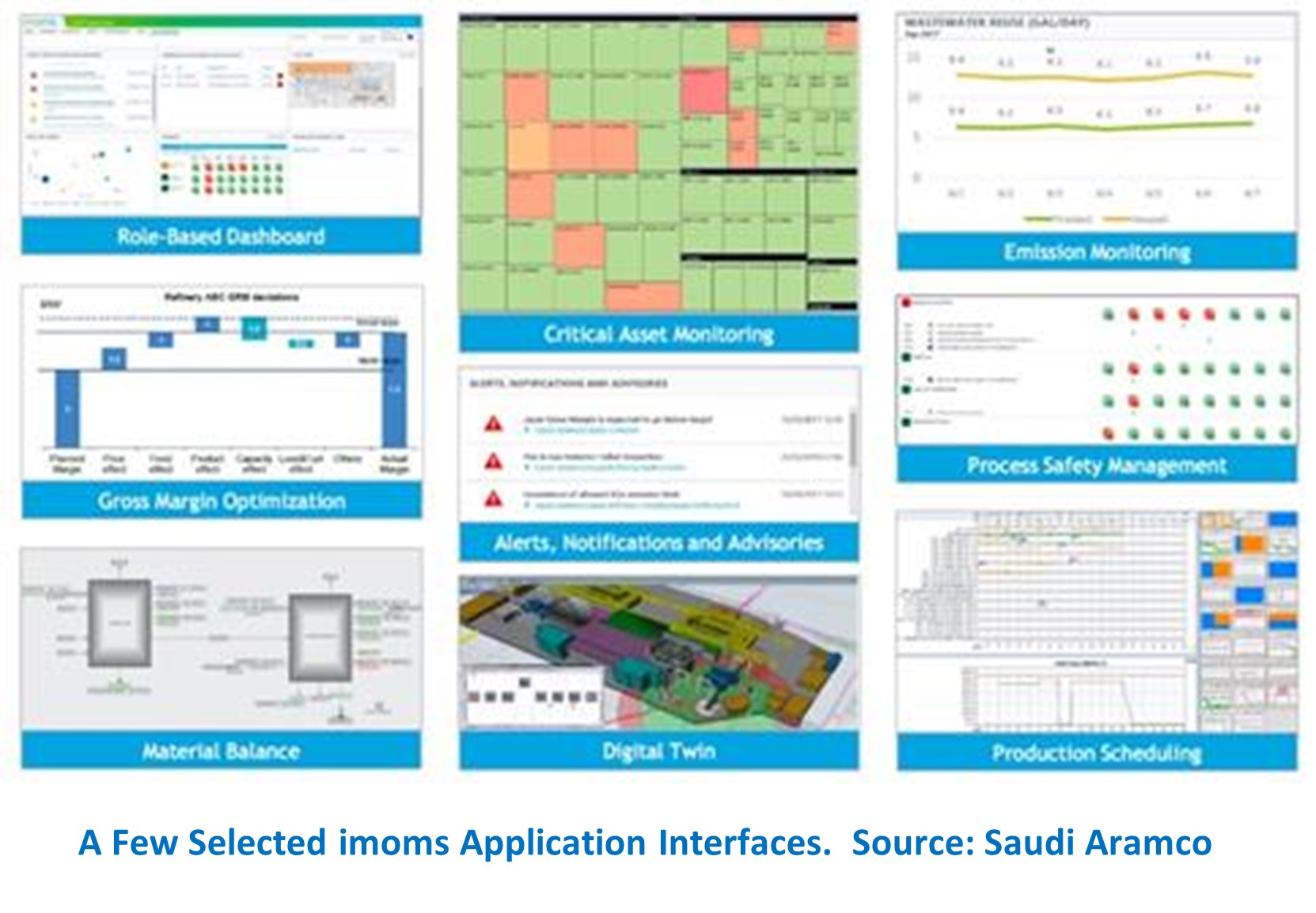

Solution architect Shashikant Ramsangar spoke about Saudi Aramco’s digital transformation (DT) journey in the company’s global manufacturing activities. A corporate team aligned employees’ input with business objectives and the ISA-95 standard, to come up with a refreshed version of the “integrated manufacturing operations management system” or “imoms”, containing five solution domains, each with existing, improved or new applications: Production Operations Management, Inventory Operations Management, Quality Operations Management, Reliability and Integrity Management and Regulatory Compliance Management.

The applications in these domains are fed with data from Operations Technology- and IT-type sources, and have common visualization, KPI and dashboarding tools. The team has enriched the data sources and visualization modes, with e.g. augmented and virtual reality, smart wearables, robots and drones, AI, and social collaboration tools.

The result are innovative solutions that are being extended across the company’s downstream business line including refineries, gas plants and joint ventures. The company expects benefits in the areas of emissions, energy costs, asset uptime and utilization, maintenance cost, spare part inventory, asset life and margins.

The recordings of the all the forum sessions will be available until the 18th of June 2022. The recording of the MESA session will be available for a longer time. There is no fee for ARC Advisory Service clients, Digital Transformation Council (DTC) for users, speakers and panelists of this Forum. An insight covering the session in depth is available through ARC’s website.