The General Motion Control (GMC) Selection guide is designed to help organizations select the best general motion control technologies and supplier for their unique business requirements.

Choosing the right general motion control supplier and technologies to operate your plant can be one of the most important decisions you will make for your business operations for years to come. If you are unsure about any of the key trends in the market or are in need of purchasing criteria, then you need the assistance that ARC Advisory Group has to offer.

ARC is the industry leading provider of market knowledge, trends, and supplier information for general motion control worldwide. Our products and services integrate hands-on experience with global market research to deliver the intelligence you need.

The general motion control market remains fragmented, with a broad and geographically diverse range of suppliers, and a plethora of possible applications affecting dozens of industries. There are a multitude of suppliers offering general-purpose solutions that are focused on a single application or specific industries; however, this characteristic of the market is more a function of the limited human resources capable of addressing specific knowledge. General motion control systems cannot be characterized as a product, but rather as a complex integration of technologies combined with application know-how to achieve the goal of automating complete machines.

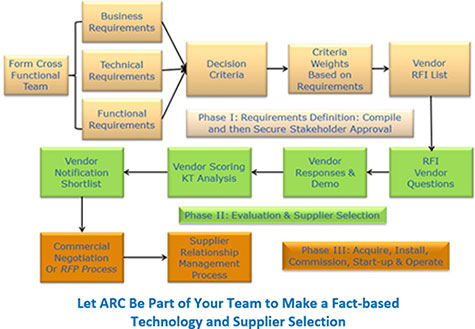

The selection process begins with a definition of the scope of the project, including production processes, number of plants, and integration with other systems. With this understanding, an organization can make the appropriate team member assignments. Reviewing and editing the ARC-provided selection criteria to ensure that the list fits your needs requires a team effort. ARC recommends that once the list is complete, you develop the appropriate questions for suppliers. This organized and logical list of criteria can provide the basis for a Request for Information (RFI) that you send to suppliers you wish to consider. Evaluating supplier responses and developing a final ranking of RFI results is also a team effort. This process helps ensure inclusive, fact-based, impartial supplier evaluations and selections, while avoiding bias issues that typically hamper these activities. Incorporating the ARC selection criteria helps reduce effort and timespan for a supplier selection process, providing faster time to benefit.

The following are a few of the supplier and technology selection issues that end users should consider:

The selection of components and final integration into production machinery are relatively complex processes. As machine builders continue to improve both mechanical and electrical designs, it is ever more critical to develop a strategic plan that embraces the latest trends in technology. Developing a strategic roadmap is essential as it provides a vision for your organization to embrace as well as communicate to your customers that you are forward-thinking.

Global megatrends are rapidly transforming the industrial operations of end users. Suppliers now must embrace smart technologies and have deep application knowledge to offer valued solutions to end users. To this end, digitalization presents a huge opportunity for end users and suppliers. While digital transformation is picking up speed and is a catalyst for long-term competitive advantage for end users, this digital technology also creates new business opportunities and better services for suppliers. Digitalization helps create a path for the transition toward more connected and smarter systems to drive increased end user value.

Users need to evaluate a supplier for not only its product portfolio, but also its solution capabilities for automation solutions. End users need to evaluate suppliers for the important aspects of application. These aspects include:

General motion control products are being updated with new features to fulfill many market demands and increase their value proposition, such as the growing demand for smart connected products based on, for example, the Industrial Internet of Things (IIoT) or Industrie 4.0. Smart connected products provide opportunities to increase operational efficiency from the plant floor to the supply chain by optimizing data, information, and analytics ranging.

ARC has been researching the general motion control market for many years, and we understand the challenge companies have in selecting and implementing a solution that will meet their simple unit, machine, or plant-wide requirement. These include:

To be able to make an informed choice, you need to know who the major suppliers servicing this market are. These guides will provide you with the names and links to information about them.

For more information on this technology guide or to discuss how we can help you, please contact us.