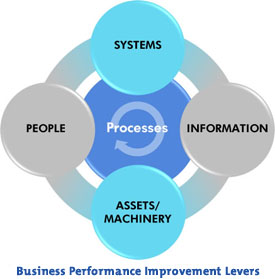

Manufacturing executives must carefully balance and optimize the performance of all plant processes and systems using all Business Performance Improvement Levers .

The pace of change in the industrial space continues to accelerate, driven by global competition, regulatory and security needs, and potentially disruptive information technology. In order to respond effectively, companies should focus on the five 'productivity levers,' or categories of things that can be acted upon in order to bring about desired changes: People, Processes, Systems, Information, and Assets (Things).

People

The people dimension, with its social and cultural opportunities and complications, is an obvious place to start, because many positive changes can be brought about through good management. But there are also opportunities to leverage new technologies to foster collaboration, provide easy access to remote experts, speed communications, and improve team and project performance.

The people dimension, with its social and cultural opportunities and complications, is an obvious place to start, because many positive changes can be brought about through good management. But there are also opportunities to leverage new technologies to foster collaboration, provide easy access to remote experts, speed communications, and improve team and project performance.

Processes

Plant IT systems leveraging advances in cloud, social, connectivity, software and analytics enable companies to adopt new and more efficient business models, improve asset performance and reliability, improve customer relationships, reduce energy consumption, and pursue new opportunities.

Systems

Virtualization, cloud computing, in-memory, and enhanced network connectivity are among the IT technologies that companies are increasingly deploying in their quest to improve performance and flexibility and reduce costs. Keeping these systems secure is a top priority.

Information

Big Data and analytics tools can help companies make better decisions and optimize performance based on data, deeper understanding, and better business insights.

Assets

Industrial assets are getting smart, and becoming equipped to communicate with analytics, the cloud, and applications. The Industrial Internet of Things (IIoT) starts with connected assets and analytics, but extends to connected workers, connected services, connected supply chain, connected enterprise, and connected products.

Improving Business Performance with IIoT

IIoT and Industrie 4.0 offer examples of new technologies that provide an opportunity to improve business performance for both owner-operators and OEMs:

- Plant owner-operators: Operational and business process improvements through removing waste and/or better work flow

- Original Equipment Manufacturers: New sources of revenue by extending the company’s business model into aftermarket services

With IIoT, equipment-related data is combined with analytics to help assess an asset’s health for early detection of a fault before failure and unplanned downtime occur. Detecting and repairing a fault before it cascades into extensive destruction of other parts and equipment significantly reduces the costs for repair and avoids costly unplanned downtime.

See a YouTube video recording of the author’s presentation of this topic with additional information during a recent ARC Forum.