I

It is common for owner-operators to be in compliance with safety standards from FAT/SAT up to plant startup and commissioning. That's an exemplary beginning, but the ultimate goal should be to exceed the minimum safety requirement specifications by being able to prove compliance throughout the entire operating lifecycle of the plant.

By working with their automation and safety system suppliers, end users can benefit from a value-adding workflow that could help them prove compliance over time, even as plant production assets and automation systems evolve.

Most end users comply with international standards that require safety lifecycle management. However, they may find it challenging

While end users may have compiled a great deal of recent proof test data, those data are likely stored in an isolated location and not integrated or shared either with their computerized maintenance management system (CMMS) or with the enterprise-level production and work process management systems.

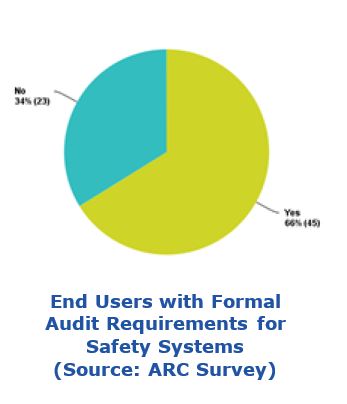

ARC Advisory Group has been speaking with end users as part of our research into safety lifecycle management practices and compliance. When asked about this subject, most users focused on compliance, compliance assessments, and their ability to prove compliance.

The safety integrator and end user communities alike have been focused on defining safety requirements, determining safety integrity levels (SIL), and layer of protection analysis (LOPA)-driven designs. In the past, ARC highlighted that many automation and safety system suppliers do not provide end users with a comprehensive solution set for safety lifecycle management. We believe that this represents an opportunity for technology suppliers and end users alike.

From an operations and safety point of view, end users should be asking themselves about their safety lifecycle management current practices:

With help from their automation and safety system suppliers, end users can benefit from a workflow that, previously, they may just have regarded as a compliance exercise. This presents an opportunity for the suppliers to provide value-adding functionality. Unfortunately, many automation companies have not provided a full solution for safety lifecycle management. Instead, some attempted to adapt their limited offerings to be able to meet the end users’ more comprehensive needs. ARC has observed that those needs change as process safety expertise has matured and new technologies have transformed the global economy.

Most of the emphasis so far has come from the “definition and implementation” side of safety lifecycle management. As previously mentioned, the vast majority of industrial organizations are in compliance with safety standards up to the time of startup. While that’s good, it’s not the ultimate goal.

That goal, according to the standards, is to go beyond the minimum safety requirements specification and past the FAT/SAT through startup. ARC research shows that the majority of owner-operators comply with both IEC 61511 and ISA-84.00.04…up to a point. We have observed that different plants display different behaviors following startup that relate to essential elements for maintaining compliance with SIL requirements and protective or mitigative requirements.

Ostensibly, all is well until the equipment is started up. Most end users perform proof tests at calculated intervals and store the results (ideally, in electronic format). But this does not go far enough and ARC believes it points to an unmet need within the user community.

Automation and safety system suppliers typically offer tools to help determine required SIL levels. These may include some rudimentary utilities that enable them to show some level of traceability for changes to the logic solver programming. While many suppliers do not offer a full suite of software that provide traceability of safety instrumentation maintenance activities, ARC has observed a shift over the last several years away from custom safety lifecycle management approaches toward offerings that promise and deliver a full solution. These can deliver and/or support:

Standards organizations are collaborating and have developed recommendations for end users that cover both SIL determination and best practices for safety lifecycle management. Those organizations are taking a broader view of production operations that highlight for end users that being in compliance with safety lifecycle management requirements involves proving compliance beyond their site acceptance tests and the production commissioning of their equipment, controllers, and process.

If end users were able to meet this expectation with an integrated end-to-end electronic method, they would also have a solid foundation upon which to build a full process safety management program.

So, the question is whether end users can operate both more safely and more profitably, or are the two mutually exclusive. The answer to that question depends on the answers that end users can provide for the following questions:

You may have documented proof that you started up with particular settings, but everything degrades over time. Equipment ages and wears, procedures become blurred, and people become complacent and believe the results of their basic safety KPIs. They get lulled into a false sense of safety. History has shown that this is usually when a big incident happens.

It is necessary to ensure that your automation suppliers give you enduring, secure, non-customized data integrations between your safety software applications and the other systems that comprise your complete operation.

Safe behaviors and practices touch all aspects of your operations. SIL determinations, hazard mitigations, and SIF maintenance issues endure long past the time you start up your units.

Based on ARC research and analysis, we recommend the following actions for owner-operators and other technology users:

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Safety Instrumented System (SIS), Safety Lifecycle Management (SLM), Safety Instrumented Function (SIF), Safety Requirements Specification (SRS), Process Safety Management (PSM), Factory Acceptance Test (FAT), Site Acceptance Test (SAT), ARC Advisory Group.