Organizations in today’s asset-intensive industries continue to seek new and novel ways to increase efficiency, productivity, and worker safety, which are top priorities for maintenance and operations teams. To better meet today’s increasingly demanding expectations, industrial organizations seek better ways to connect and communicate, both within and across plants and factories and remotely from the field or from workers’ homes.

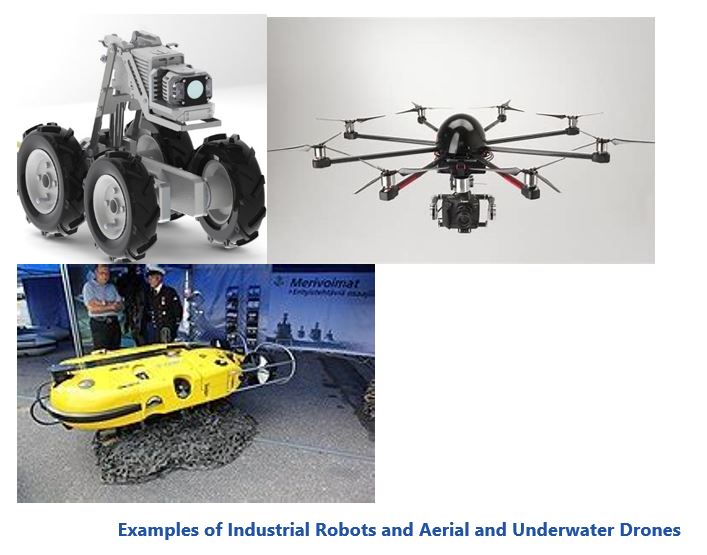

Increasingly, this is being accomplished utilizing Industrial IoT-connected sensor data, and applications along with connected industrial robots, and drones.

In addition to responding to ever-increasing customer needs, responding to global competition, and – now - managing through a global pandemic, maintenance and operations teams must do more with less. Not only must they often be available 24/7, these often resource-strapped teams must manage in challenging, and often harsh environments.

Industrial IoT is at the center of a revolution in maintenance and operations and these teams must now consider how best to incorporate such capabilities as autonomous or semi-autonomous operations in plants and other industrial facilities.

End user interest is growing in response to increased demand for innovative, efficient, and safer ways to inspect, clean, monitor, adjust, and move various asset-related components.

In addition to delivering efficiency and productivity benefits, emerging technologies can make life easier – and safer – for frontline personnel. Industrial robots and drones, for example, excel at tasks that are repetitive, tedious, undesirable, not easily accessible, or dangerous, to hu-mans. Robots and drones can relieve humans from having to work in hazardous environments, as well as perform some tasks humans are not willing or able to do for extended periods of time.

Robots, drones, and other emerging technologies, however, tend to be highly specialized and some can be quite expensive. But technology advances are addressing these and other issues. In many cases, consulting services from suppliers and systems integrators are needed to ensure proper implementation, calibration, and operation.

Industrial robots and drones are particularly well-suited for performing inspections (especially inspections that require awareness of specific equipment characteristics), rounds, surveying, and remote scanning and cleaning.

Robots and drones are also well-suited for performing tasks in dangerous environments, such as:

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Industrial IoT, Robotics, Drones, Robots, Predictive Analytics, Enterprise Asset Management (EAM), Maintenance, IT, OT, COVID-19, ARC Advisory Group.