February 6-9, 2017 - Orlando, Florida

Digital Enterprise Comes into Sharper Focus at 2017 ARC Industry Forum

The 2017 ARC Industry Forum represented the 21st edition of this annual event. The Orlando Forum seems to attract more and more quality speakers, participants, and sponsors every year. It provides an opportunity for thought leaders from technology end user organizations, technology suppliers, academia, and government to convene to discuss emerging technologies and trends and share use cases. This event also often serves as a catalyst for important industrywide initiatives. This year was no exception.

Following the Sunday night, pre-Forum Super Bowl Party that has become a tradition in recent years (and what a Super Bowl it was!); a full day of interactive workshops, press announcements, and a welcome reception on Monday; the 21st Annual ARC Industry Forum officially kicked off with a series of thought-provoking keynotes at the Tuesday morning general session. The three General Session keynotes covered industrial cybersecurity, the Open Process Automation initiative, and the digital enterprise, respectively. Not surprisingly, many common themes resonated through all three presentations, not the least of which is that while connectivity is good, it must be implemented with rigorous, ongoing attention to cybersecurity. Following the General Session, the close to 800 registered Forum participants had the opportunity to attend topical sessions in five dedicated tracks. These ranged from automation and cybersecurity, to IIoT-enabled asset management, digital platforms, and analytics.

Cybersecurity: “Marty Unplugged,” or “Find That Red Button”

Marty Edwards, the lead-off keynote speaker at this year’s Forum, is the Director of Industrial Control Systems, Cyber Emergency Response Team (ICS-CERT) at the US Department of Homeland Security. Significantly, Mr. Edwards brings a strong industrial control system background to this important position, both at Idaho National Labs and in the private sector.

Marty Edwards, the lead-off keynote speaker at this year’s Forum, is the Director of Industrial Control Systems, Cyber Emergency Response Team (ICS-CERT) at the US Department of Homeland Security. Significantly, Mr. Edwards brings a strong industrial control system background to this important position, both at Idaho National Labs and in the private sector.

Mr. Edwards began his talk by throwing out the hypothetical question: “We’re all going digital, but what is digital?” He went on to explain, that the definition of “digital” has changed since the old “3 to 15 psi days.” This referred to the pre-digital (and, in fact, largely pre-electronic) days when field devices in industrial plants often communicated their measurements to dedicated, single-loop pneumatic controllers via compressed air signals.

Back then, controllers weren’t connected to a network and “digital” literally referred to bits and bytes. Today, in contrast, “digital” often means “connected,” he explained. He provided one thought-provoking example of how connectivity has ramifications across multiple dimensions. In this case, a police department in the US had used data transmitted from a suspected arsonist’s pacemaker to monitor the suspect.

“Now that we’re connected, we have to start talking about security – because connectivity and security often don’t work well together, and an ‘air gap’ approach to security is no longer enough. Ten years ago, we would have been preaching that you absolutely should not use IT security in a control system, because you’d be likely to break it. Today, there’s great potential for IoT-type security, many instances of which contain security from the ground up and products that are hardened ‘right out of the box.’”

“We still see companies that don’t perform due diligence, with the number one challenge being lack of adequate perimeter security.” Even worse, security breaches are often not adequately logged, so when management asks “what happened?” the answers are not readily available. “At the end of the day, a determined nation state could breach any system.”

This led Mr. Edwards into a discussion on the concept of “cyber-informed engineering.” The concept is simple: “In your facility, find the most critical of functions. Once you’ve identified that basic function, take it offline.”

He explained that in years gone by every industrial facility had big, red dedicated buttons mounted in strategic areas around the plant that employees could use to shut down a critical function in case of a mishap. Today, however, these “red button” types of safety shutdown functions have been digitized and connected. “Those one or two critical functions need to be taken offline by creating specialty circuits for them. It’s important to apply the correct level of technology – but no more than is really needed.”

Mr. Edwards summarized his presentation in this manner: “It’s important to perform a proper risk assessment to identify the one or two critical functions in the plant,” and then apply particular protection to those functions via separation, redundancy, etc. “In other words, find that red button!” With that in mind, “Marty Unplugged,” is what he told us he really would like to call his talk.

Open Process Automation: “Looking Outside the Box”

For the second consecutive year, Don Bartusiak, Steve Bitar, and other ExxonMobil executives participated in the ARC Industry Forum to present and garner additional support for the important Open Process Automation initiative that ExxonMobil has initiated. Mr. Bartusiak, Chief Process Control Engineer at ExxonMobil Research and Engineering, began his keynote presentation at this year’s Forum by outlining the business problem:

- With many of the company’s large installed base of distributed control systems (DCS) at or rapidly approaching obsolescence, there’s a driving need to replace those systems.

- It’s critical to lower both the replacement and ongoing lifecycle costs for DCSs and derive more value from automation investments in general.

- Current available DCSs do not solve the above problem and the root causes are both technical and commercial.

According to Mr. Bartusiak, “Our goal is a standards-based, open, secure, and interoperable system. We need security that is built into the system and not bolted on. And we’d like to see commercial systems by 2021.” He then went on to explain the background.

According to Mr. Bartusiak, “Our goal is a standards-based, open, secure, and interoperable system. We need security that is built into the system and not bolted on. And we’d like to see commercial systems by 2021.” He then went on to explain the background.

“In 2010, when we began the R&D for replacing the fleet of control systems in our downstream refineries and chemical plants, we tried to look outside the box and found good solutions in the aviation, telecommunications, and IT worlds.”

In avionics, the work of Future Airborne Capability Environment consortium (FACE) has resulted in open modular systems. The telecommunications industry has developed cell tower-based systems with network function virtualization and software-defined networking. And the IT world has developed cybersecurity innovations that could be applied to OT. Bartusiak also mentioned that the emergence of IIoT, wireless, and cloud services drive expectations for change.

In 2014, Bartusiak’s team developed the functional characteristics needed to engage industry. In 2015, the company contracted Lockheed Martin to define the requirements and integrate the prototype system. In 2016, ExxonMobil and The Open Group formed the Open Process Automation Forum to develop standards. The vision developed by this largely end user-driven group includes the following system characteristics:

- Best-in-class components; with leading-edge performance

- Conformant components integrated for systems that are fit-for-purpose for end user’s needs

- Adaptive intrinsic security

- Commercially available and applicable across multiple industry sectors

- Protect suppliers’ intellectual property

- Portable end user software

- Simplify replacements; reduce lifecycle cost

- Expanded markets for suppliers and system integrators for components and services

- Innovation and value creation

Bartusiak explained that the Open Process Automation Forum of The Open Group “opened for business” in September 2016 and held its inaugural meeting for member companies on November 16 and 17. As of January 20, 2017, there were 20 member organizations. These include end user companies spanning a variety of industries: Aramco Services, BASF, Chevron, Dow Chemical, ExxonMobil, Koch Industries, Merck, Praxair, and Shell. DCS vendors include ABB, Emerson, Honeywell, Schneider Electric, and Yokogawa. “DCS-adjacent” companies include GE, netControl, and Siemens. A number of well-known hardware, software, and SI companies are also members.

He pointed out that four Open Group members were participating in this ARC Forum and gave credit to the various trade journals as well as to ARC Advisory Group for their respective support. Based on the interest we heard expressed in Orlando this week, ARC believes that it is likely that at least one or two additional large end user organizations will soon sign up as members.

Next, Bartusiak discussed the likely impact on traditional automation suppliers. For obvious reasons related to their installed bases, suppliers have been closely monitoring the progress of the initiative, which is also likely to seriously disrupt their supply chains. He believes that, despite some obvious challenges for suppliers, those that can adapt to the new environment will ultimately benefit from reduced systematic costs, increased margins by focusing on differentiating advantages, and revenue growth from the expanded market size and opportunities.

“In one respect, we’re almost at the same point right now where we were when each railroad company used its own rail gauge,” so trains from one company couldn’t operate on another company’s rail system.

“We’re on a 20-year technology refresh era with DCS – we just have to change. Based on the lessons from our history in standardization activities, end users need to get actively involved here and “help make the sausages,” concluded Bartusiak.

Andy Chatha: Let’s Work Together and “Go Digital”

Andy Chatha, ARC Advisory Group’s president and founder, once again focused his own keynote address on where he believes industry is headed. Always the visionary, Andy focused on the need for open systems, digital transformation, and how cybersecurity is key for both.

According to Andy, “Going digital can make companies more agile and responsive. Companies look to increase their revenue and make smarter products that can provide both new opportunities to increase their services business, and opportunities for technology users to improve their operating performance and agility. But of course, how you go digital will depend on your particular company and business processes.”

According to Andy, “Going digital can make companies more agile and responsive. Companies look to increase their revenue and make smarter products that can provide both new opportunities to increase their services business, and opportunities for technology users to improve their operating performance and agility. But of course, how you go digital will depend on your particular company and business processes.”

“We need open systems all the way to the top; it’s critical for all your systems to work together, but to do so in a manner that does not increase cybersecurity risk. The latest move in analytics is to start embedding analytics into your systems.” Andy believes that this offers many opportunities to improve operating performance and return on assets. “Soon, companies will start adding applications on top of their platforms, as well as start turning their applications into platforms.

The most important point is how to get the many different platforms and applications available today to work together and be interoperable. “Make sure that the platforms you bring into your plants work together.” He then discussed some of the many potential opportunities that digitization could bring across a variety of process, discrete, and utility industries.

Next, Andy discussed ARC’s expanded Asset Performance Management (APM) Maturity Model, which now includes a fifth level of maturity -- prescriptive maintenance -- made possible through IIoT-enabled connectivity, advanced analytics and machine learning, and advanced modeling techniques. With prescriptive APM, the model and knowledge base not only identify an issue, they provide specific guidance for how to best respond to that issue.

According to Andy, “The digital enterprise will be a game changer and it all starts with smarter machines and other connected assets.” To this end, “Cloud makes it less expensive to connect sensors, devices, and systems to enable you to run more predictive/prescriptive analytics on appropriate assets and selectively share plant data with suppliers.” Andy believes that this journey will take years; but will be worth it.

The old paradigm, “Make your product and they will come,” no longer applies. Increasingly, customers will demand products that are customized to their needs and preferences. We need new blood and new companies to help us in this transformation.

“Change is hard, no one likes change. But this is also an opportunity to leapfrog to the newer technology in our plants. However, in the end, it always comes down to execution.”

Client Testimonials

Attendee Perspectives

At the ARC Forum, I recognized challenges I face and learned how they are being solved by many companies across multiple industries using really innovative approaches. I walked away with ideas of how I could do things tomorrow in new and better ways. As well, I also had a chance to help others work through some of their challenges that I had already faced and overcome. That two-way dialogue with my peers, especially those in other industries, was eye opening for me as a utility professional dealing with significant industry transformation.

Dwayne Bradley

Technology Development Manager, Emerging Technology Office

![]()

Attending an ARC conference delivered lots of value for me. It’s a great learning experience with great networking opportunities. Very enlightening. The conference was an excellent source of the latest information on IoT, supply chain, and manufacturing techniques and practices. But even more important, was the opportunity to learn about future technologies and opportunities to help us strengthen our business model. This included some good, hands-on information. I thoroughly enjoyed the conference and look forward to attending next year.

Jan Thiessen

Director, Strategy & Methods, Global Purchasing & Materials Management

![]()

Featured Keynote Speakers

The following executives will give the Forum's Keynote Presentations.

Marty Edwards

Director, Industrial Control Systems Cyber Emergency Response Team (ICS-CERT)

Director, Industrial Control Systems Cyber Emergency Response Team (ICS-CERT)

U.S. Department of Homeland Security

Marty is the Director of ICS-CERT, an operational division of NCCIC (National Cybersecurity and Communications Integration Center) and the DHS Office of Cybersecurity and Communications. ICS-CERT works to reduce industrial control system risks within and across all critical infrastructure sectors by coordinating efforts among federal, state, local, and tribal governments, as well as industrial control systems owners, operators, and vendors. ICS-CERT responds to and analyzes control systems related incidents, conducts vulnerability and malware analysis, and shares and coordinates vulnerability information and threat analysis through products and alerts. Marty has over 25 years of experience and brings a strong industrial control system industry focus to DHS.

See information on ARC's Cybersecurity Program at the Forum.

Don Bartusiak

Chief Engineer, Process Control

Chief Engineer, Process Control

ExxonMobil Research & Engineering

Don is responsible for setting technology strategy for instrumentation, process analytics, control systems, and applications for ExxonMobil, including interactions with other ExxonMobil companies regarding process control. He assists line management with career development of about 900 process control staff globally. He has 29 years of experience in ExxonMobil as an individual contributor (real-time artificial intelligence, regulatory control, real-time optimization, and non-linear model predictive control) and in management positions. He has authored 4 patents and 9 articles.

See information on ARC's Open Automation Program at the Forum.

Partial List of Executive Speakers

The following executives will also be among those presenting at the Forum. For more information, please visit our speaker section on cvent.

Michael Carroll

VP, Innovation and Operations Excellence

Georgia-Pacific

Liu Qiao

Technical Director, Software Electronics Mechanical Systems Lab

3M

Laura Sheets

Tritium Process Control Lead Engineer

Savannah River Nuclear Solutions

Steve Bitar

R&D Program Manager

ExxonMobil Research & Engineering

Justin Fishkin

Chief Strategy Officer

Local Motors

Jeff Russell

Southeast Regional Engineering Manager

Pepsi Beverages

Kevin Wilhelm

Senior Consultant

Eli Lilly

Tyler Williams

Global Technology Leader

Shell Global Solutions

William Prusha

Corporate Architect

Eastman Chemical

Julie Smith

Global Automation & Process Control Leader

DuPont

Glen Mutscher

Global Director, Manufacturing & Engineering

Dow Chemical

Doug Lutz

Principal Process Automation Engineer

NOVA Chemicals

Devavrat Bapat

Sr. Director, Supply Chain Transformation and Analytics

Johnson & Johnson

Adam Sedgewick

Senior Information Technology Policy Advisor

National Institute of Standards and Technology

Helen Dotson

Global Process Automation Technology Leader

Dow Chemical

David Hoeppner

Control Systems/Electrical Department Manager

Fluor

David Lawrence

Technology Development Manager, Emerging Technology Office

Duke Energy

Gene Tung

Director of IT

Merck

Scott Harmeier

Process Optimization Manager

Archer Daniels Midland

Christian Klettner

Automation Manager

BASF

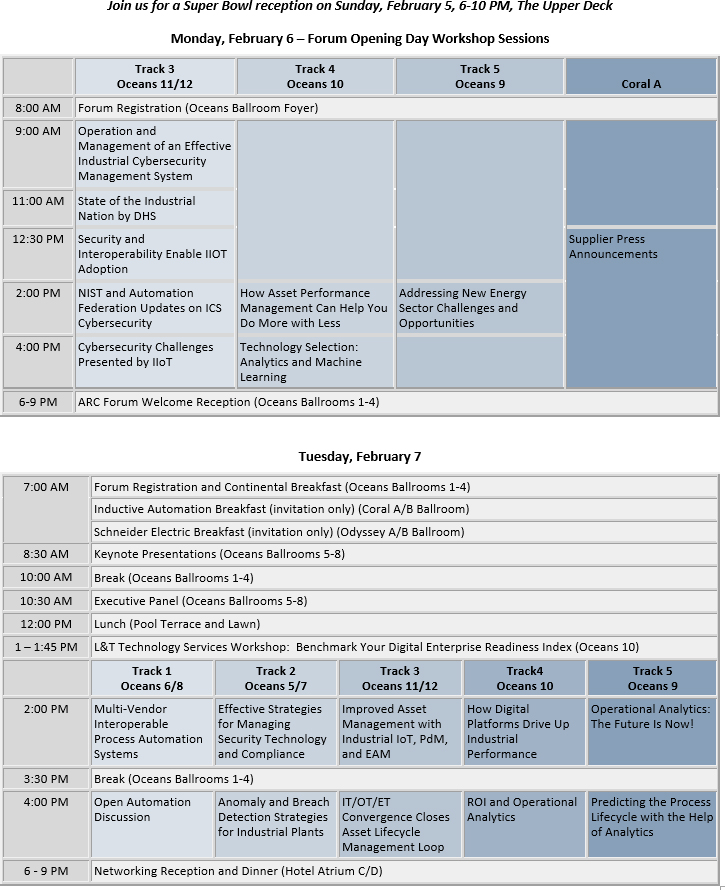

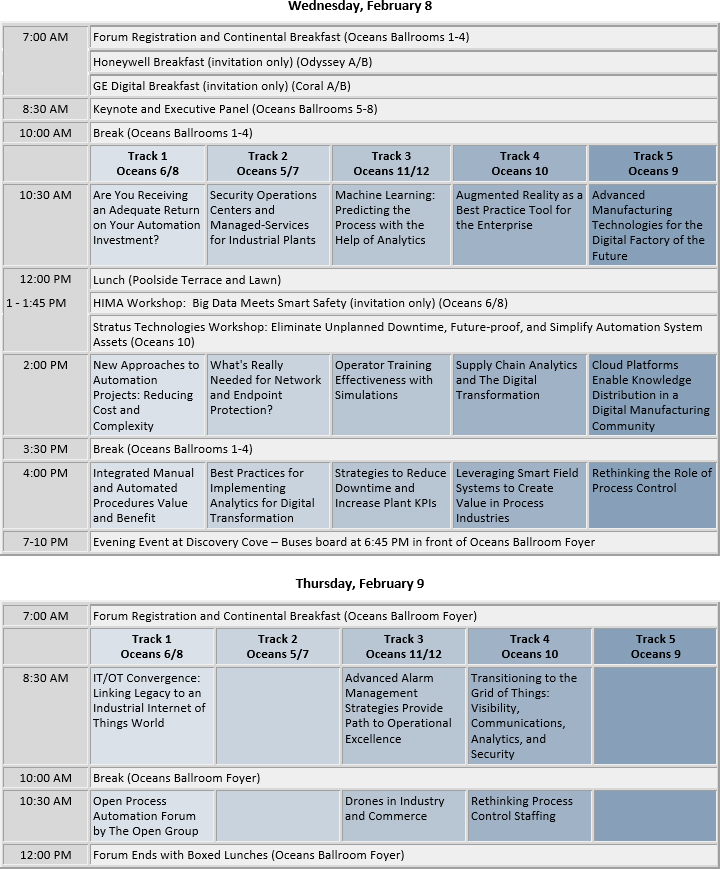

Agenda

For the agenda and session descriptions, please view our agenda on cvent (click on session name for description).

Agenda at a Glance:

Innovations Showcase

New industry solutions are on display at the Innovations Showcase. The Showcase provides an excellent opportunity for executives to assess the potential for emerging applications in production management, interoperability, virtual manufacturing, process improvement, asset management, operations management, supply chain synchronization, and more. Exhibits have application scenarios for attendees to see how emerging technologies are applied to help solve issues across all industries.

The Showcase is open during the Monday Evening Reception and during breakfasts, breaks, and lunches. It is held adjacent to the forum where refreshments are served.

Location

The Forum is held at the Renaissance Orlando Hotel in Orlando, Florida.

The Forum is held at the Renaissance Orlando Hotel in Orlando, Florida.

Renaissance Orlando at SeaWorld

6677 Sea Harbor Drive

Orlando, Florida 32821

renaissanceseaworldorlando.com

Orlando Visiting Information

Please contact Orlando's Visitor Information Center at 407-363-5874, www.visitorlando.com, for information regarding current events in Orlando. For discounted attractions in Orlando, please visit Orlando Convention Aid website. Their on-line travel guide offers discounts to restaurants, golf, attractions, nightlife, shopping, and more, including making dinner reservations for you.

Previous Attendees

The following companies have attended recent ARC forums:

Aerotech

aeSolutions

Agilent Technologies

Air Liquide

Akzo Nobel

Alliance Pipeline

AMEC Natural Resources

Anglo American

Archer Daniels Midland

Areva

Axiall

Azbil

Baker Hughes

Beckhoff Automation

BHP Billiton

Blackrock

BorgWarner

Bosch Rexroth

Brady

C-Labs

Cal-Amp

Cambell Soup

Cenovus Energy

CF Industries

China Yangzte Power

Church & Dwight

Comau

Connacher Oil and Gas

Consumers Energy

Cummins

Danaher

Dell

Descartes Systems Group

Dominion Virginia Power

Dow Kokam

DTE Energy

Duke Energy

Eaton

Electro-Matic Products

Elkay Manufacturing

EMC

EQUATE Petrochemical

Festo

Flint Hills Resources

Freeport McMoran

GE Aviation

Genpact

Goodrich Petroleum

Goss International

Greater Cincinnati Water Works

Hirschmann Automation & Contro

HubHead

Independen Belgian Refinery

Inductive Automation

Industrial Defender

Industrial Evolution

Infosys

Innominate Security Technologies

Intergraph

International Paper

Iscar Metals

JHP Pharmaceuticals

John Deere

Joy Mining Machinery

KapStone

Kollmorgen

Kongsberg Oil & Gas Technologies

KUKA

L&T Infotech

Lafarge

Lakeland Electric

LifeCare Services

Lockheed Martin

Lopez Foods

LyondellBasell

M+W Automation

Manufacturing Connection

Marathon Electric

Mark Andy

Maverick Technologies

MaxGrip

Mentor Graphics

MESA

Mettler Toledo

MillerCoors

Momentive Specialty Chemicals

Morgan Stanley

Mori Seiki

Nalco Champiion

NAMUR

NEMA

North West Redwater Partnership

Northwest Analytics

NovaTech

ODVA

Okuma America

OLDI

Pacific Northwest National Lab

Palmer Foundry

Panasonic

Panduit

Paper Converting Machine

Parker Hannifin

Patti Engineering

PCN Technology

Petro Rabigh

Petrobras

Phoenix Contact

PLCopen

POSC Caesar

Profibus & Profinet International

ProSys

PTC

Public Service Co. of New Mexico

Quiet Logistics

Rackspace Hosting

Red Arrow Logistics

Rich Products

Rolls-Royce

Rotork

Ryder System

Sabic

Sabisu

SAIC

Sans Institute

Sekuworks

Shaw Power Group

Shell Exploration & Production

Skkynet Cloud Systems

Smurfit-Stone Container

Sony Electronics

Telecom Industry Assoc.

Tetra Pak

TOTAL

Toyota Motor Manufacturing

Trend Micro

U.S. Department of Energy

Universal Parks & Resorts

Vale

Valero Energy

Vallourec & Mannesmann do Brasil

VIA Information Tools

Walt Disney World

Wells Enterprises

Whirlpool

Wipro Technologies

Wurldtech Security Technologies

Xerox

Yanbu National Petrochemical

Yaskawa