ARC Advisory Group has identified a strong trend for owner-operators to engage with a Main Automation Contractor (MAC) to supply, coordinate, and/or manage all automation-related aspects of a major capital project. This is largely because most owner-operators no longer have large in-house automation departments to manage the extensive network of automation contractors and subcontractors needed for the increasingly more ambitious and complex projects we’ve seen emerge in the recent past. In this environment, MACs can and do provide significant value.

The scope of automation is also expanding. In today’s information-driven manufacturing environment, it’s essential for more information processing to be performed close to the plant floor and for appropriate production and business data to flow smoothly between production and business systems. Plant instrumentation and automation systems play a key role in information-driven manufacturing since, in addition to helping ensure safe and secure operations, they also generate the vast majority of real-time operational and asset data consumed by higher level systems.

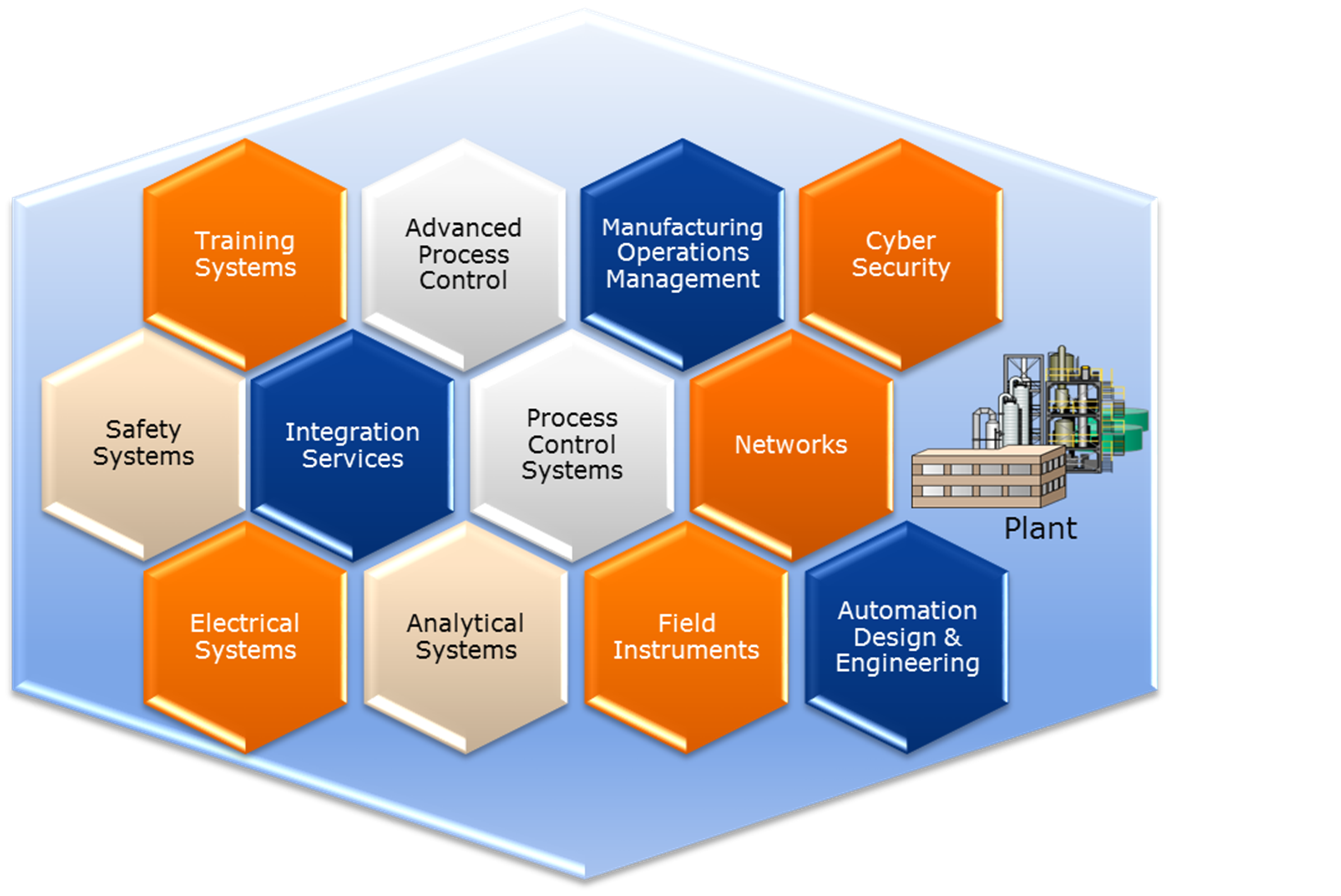

Typically, the Main Automation Contractor’s role is not only to design, engineer, and deliver all automation-related equipment and systems (field instrumentation, control systems, safety systems, etc.); but also to ensure that these systems are integrated safely and securely and supported by the appropriate services. Increasingly, MACs are also being asked to integrate the plant automation systems with the plant electrical and other systems.

While this clearly is no small task, new IT-enabled tools and technologies such as virtualization and cloud computing have emerged that serve MACs well, particularly to enable more design and testing to be performed before committing configurations to equipment. The Industrial Internet of Things (IIoT) is also playing an important role as more OEMs provide equipment with intelligence that can be accessed through the internet and more IIoT-enabled applications are implemented at the edge of the network (e.g. edge computing, analytics, etc.) to support new solutions and business models.

Additionally, the Open Process Automation Forum (OPAF) is likely to impact how MACs work in the future. This initiative began a few years ago when ExxonMobil partnered with Lockheed Martin to develop a next-generation open and secure process automation system, who suggested the Open Group be used to lead the effort. The standardized, interoperable modules envisioned by this initiative could make a MACs job much easier by workflow improvements such as, eliminating repetitive tasks and multiple ways to perform the same tasks. It is in a MACs best interest to closely follow and/or actively participate in the initiative to best learn how it could maximize value for end users.

The dramatic drop in energy prices in recent years has significantly slowed the number of new mega projects in the upstream oil & gas industry and delayed or cancelled many that were already on the books. At some point though, it’s likely that this activity will pick up again to some degree. What is certain though, is that any new projects that do emerge will be subjected to unprecedented scrutiny. No longer will project delays or cost overruns be acceptable. The handover of a well-engineered and well-integrated automation system on time, on budget, and ready for flawless operation is arguably the single most important factor of a main automation contractor’s value proposition.

Main automation contractors (MACs) typically provide a central point of coordination and responsibility for all aspects of an automation project. Many owner-operators no longer have the considerable automation departments they once had and managing the large network of automation contractors and subcontractors for a given project, particularly the large, complex and groundbreaking projects of the past decade, can be overwhelming.

In earlier days, the large, full-line automation suppliers or major system suppliers often served as MACs. More recently, however, engineering, procurement, and construction (EPC) contractors and some larger systems integrators (SIs) have also found that their clients may be looking for them to also serve as the MAC. Some system integrators and automation engineering firms have even formalized their MAC services offerings. This provides end users with more choices as to how best to implement an automation project.

One of the nagging issues surrounding major automation projects is coordinating schedules between all the participants: automation suppliers, the MAC, and EPCs. If the MAC is not the EPC contractor, often the EPC is brought into the loop only after the owner-operator and MAC have agreed upon the scope. This can lead to many problems later in the project, especially when the EPCs are unable to provide hardware or software data required in the timeframe set by the MAC. The owner-operator, MAC, EPC contractor and other parties involved must agree upon and understand the objectives, responsibilities, and commitments expected from each party.

A plan must also be in place to account for the inevitable project changes. Many MACs have either developed or acquired change management tools deployed with their EPC packages and integrated into their scheduling functions. Change management tools help mitigate the risk of falling behind schedule, as changes are well documented and incorporated into the schedule and all parties are fully aware of the changes and their impact and implications on the project.

Even though the MAC is the single point of responsibility for all automation-related issues, the owner-operator must maintain oversight, audit the process continuously, and be prepared to intervene if differences should arise between the MAC and an EPC contractor. The owner-operator should encourage and foster the idea that the collective relationship between user, MAC, and EPC is a mutually beneficial partnership and teamwork is not only encouraged but also expected.