Operators need to maintain asset integrity to avoid unplanned downtime and the associated safety and environmental incidents. Asset integrity management (AIM) focuses on pressure containing vessels like pipes and tanks to ensure that these assets deliver the required functions and performance in a sustainable manner. These systems have been proven to drive down inspection, maintenance and repair costs while improving plant reliability and operational safety. AIM manages and mitigates deterioration caused by corrosion and fatigue cracks.

The principal industry sector served by AIM suppliers is upstream oil and gas. The AIM market is primarily driven by increasing investment in the oil and gas sector to meet the escalating global demand. Other leading industries for AIM include refining, electrical power generation (like steam), and chemical.

AIM are used manage the capability of an asset to perform its required function throughout the asset’s lifecycle. The systems help ensure that the people, systems, processes, and resources that deliver integrity are in place, in use and will perform when required.

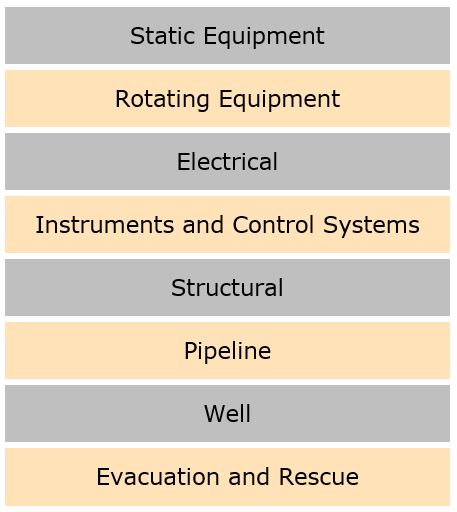

Asset integrity is managed at each stage of the asset lifecycle, including project design, asset operation and decommissioning. Inspections, auditing/assurance and overall quality processes are just some of the means to execute an effective integrity management program. A program can include:

The AIM is used to maintain the asset in a fit-for-service condition while extending its remaining life span in a reliable, safe and cost-effective manner. In the US, AIM programs are deployed to meet API-580, API-581, and PAS 55 requirements.

An asset integrity management system does not exist in isolation. To successfully implement an asset integrity management system in a dynamic operating environment, it is essential that all stakeholders have a consistent and a unified understanding of what the essentials of asset integrity are and how they can be applied in their day-to-day operations, yet this is often cited as among the most significant challenges in achieving an integrity culture within an organization.

Industrial IoT (IIoT) offers the potential for more automated collection of data which would reduce the labor intensive aspects of inspections for asset integrity management.

This market research study provides current market analysis plus a five-year market and technology forecast. ARC derives market size and share from its extensive in-house databases and in-depth interviews with leading suppliers. The EAM market study may be purchased as an Excel workbook and/or as a PDF file.

This Technology Selection Guide is designed to help organizations navigate the buying process for EAM systems. ARC determines selection criteria through research with users and an understanding of supplier capabilities. The EAM guide includes both selection criteria and strategies for choosing the best enterprise asset management software supplier to meet your business needs.