Routine maintenance and inspections are crucial for proper asset management. Regular maintenance and inspection works also help ensure workplace safety. Various new technologies can improve and simplify these routine tasks and thus improve asset integrity and reliability. Remote monitoring, autonomous vehicles, and drones are some of the latest technologies used in the oil and gas and other process industries to improve asset management.

As end user organizations across all industries continue to face a shortfall of qualified personnel, advanced

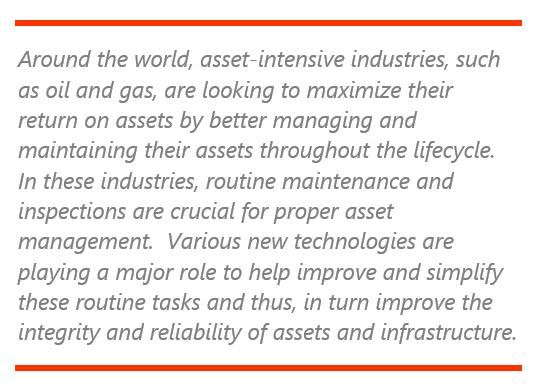

Information is gathered from the field via mobile, handheld, wired, or wire-less monitoring instruments on a continuous or near-continuous basis. Whether collected remotely, onsite, or via a combination of the two, data can be used to create predictive maintenance programs to help prevent asset failures by scheduling maintenance activities to minimize production interruptions.

Many suppliers now utilize high-definition cameras and augmented reality tools to help their customers maintain their assets. If something is wrong with an asset, such as a pump or a valve, suppliers can use those in-plant cameras to look at the malfunctioning asset from a remote location and send appropriate service personnel with necessary replacement parts. In some situations, end users could also fix the issue themselves with assistance from the supplier’s remote crew.

Drone-assisted inspection is the latest trend in the asset integrity management space. Drones have the potential to completely transform some of the inspection operations in the highly regulated, asset-intensive industries. In the US, thanks to the 2017 Unmanned Aircraft Systems Reform Act, unmanned aircraft systems (UAS) are now approved by law for inspections and other applications in industries such as oil & gas and refining.

Drone inspections also help to enhance safety for workers and inspectors. Inspectors do not need to climb ladders, use ropes, or be in sky-lifts to get to hard-to-reach inspection sites. Using drones, inspectors can distance themselves from the danger zones, making it possible to safely inspect assets in high-risk areas. For example, when an active flare needs to be inspected, a drone can collect all the needed videos and images. The drone can also be equipped with thermal imaging camera to get the necessary thermographic data, while inspectors remain at a safe distance. Furthermore, with drone-assisted inspections there is no need to shut down or disturb the production process.

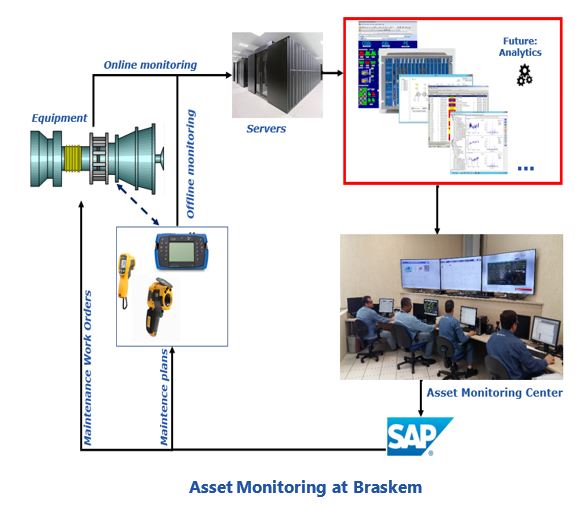

In the oil & gas industry, infrastructure and assets are often remotely located. Performing inspections and routine maintenance tasks on these remotely located assets is a major challenge in the industry. Advanced, remotely operated underwater vehicles (ROVs) are quickly gaining popularity to help perform routine tasks more easily and efficiently, especially for subsea operations.

At the 2018 Offshore Technology Conference, the organization awarded Oceaneering’s E-ROV system with its Spotlight on New Technology award. The E-ROV, a self-contained, battery-powered electric ROV with 4G connection, can be remotely operated for extended periods of time without having to surface. It can transmit control data and live, high definition video via satellite or high-bandwidth terrestrial network to be able to perform various tasks, including inspections, safely and more efficiently.

We are also seeing a lot of effort being made to employ autonomous vehicles for inspection and maintenance work. OneSubsea, a Schlumberger company, is developing its uROV inspection platform, which the company calls a supervised autonomous vehicle. The uROV merges Schlumberger technologies with Saab Sabertooth vehicles. It is equipped with multiple sensor devices, including LiDAR, a multibeam echosounder, and side scan sonar. The uROV can autonomously collect inspection data on subsea structures from close range and then transmit this data from the on-board computer through a gateway to the central control or monitoring station. With the necessary inspection information, maintenance personnel at the central control station can then make decisions on maintenance and repair operations on the structure. Clearly, autonomous or semi-autonomous vehicles such as uROV can help expedite inspection and maintenance tasks. Technologies like this also help perform necessary maintenance activities with fewer crew members, which is a great help for the industry struggling to fill the skills gap.

Today, a variety of technology solutions are available that could help owner-operators improve the performance and reliability of assets to improve asset availability and reduce corrective maintenance costs. However, we should note that technology alone won’t solve the whole problem. For an effective asset management program, end users should start with a comprehensive plan and develop a clear strategy for the project. They should make it a priority to involve the right people and then properly train them on the new technology.

ARC is prepared to assist you and your organization. Just click on the “Contact Us” here or on the icon below.

Keywords: Oil and Gas, Inspections, Maintenance, Asset Integrity Management, Drones, Remote Monitoring, Remote Operated Vehicles (ROV).