Unplanned downtime for critical equipment can negatively impact business performance, including both revenue and customer satisfaction. As equipment gets increasingly complex and experienced personnel retire, it becomes difficult for on-site, general-purpose technicians to avoid costly unplanned downtime. OEMs that offer servitization in field service, rather than just products, can provide an attractive alternative.

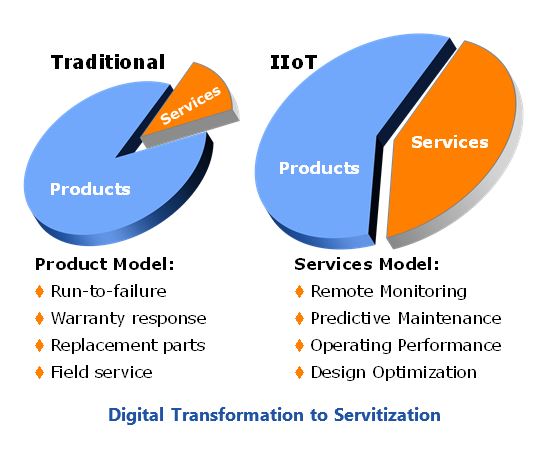

Servitization mainly involves equipment manufacturers and the shift from selling a standalone device to offering solutions that combine product and services. Servitization adds value with services and has a range of approaches.

On one end of this range, an OEM sells the equipment and provides an aftermarket service for monitoring the condition of the equipment at the customer’s location. Here, the OEM also provides the services needed to prevent unplanned downtime and improve operational performance.

On the other end of this range, servitization involves the OEM charging the customer based entirely on usage. For example, charging for cubic feet of compressed air consumed rather than upfront for the compressor equipment.

The scope of servitization includes designing, building, and delivering an integrated product and service offering that provides increased value to the user. Servitization focuses more on outcomes than just delivering a device. Beyond OEMs, this can extend to systems integration when combined with post-installation services.

Remote Condition Monitoring

Remote Condition MonitoringIndustrial IoT (IIoT) and analytics enable remote asset health monitoring and predictive maintenance (PdM). Many OEMs are transforming from reacting to a service request after their equipment fails to a proactive repair approach that prevents unplanned downtime, improves reliability, and extends asset longevity.

Remote asset health monitoring with PdM provides warning of an impending failure. The OEM or its service provider typically has an intimate understanding of the equipment. This enables it to develop algorithms for early detection of issues – sometimes up to six months prior to failures. With this advanced notice, the service provider can either alert the end user or schedule repair with its own field service technicians.

IIoT-enabled condition monitoring and predictive maintenance approaches allow manufacturers to consider outsourcing maintenance to the OEM or a specialty service provider (typically the OEM’s local dealer or distributor). Modern equipment often includes software, electronic controls, and science-based intellectual property. These systems require training and skills to maintain and repair. The service provider’s technician has extensive experience with the equipment, which provides a deep understanding of the equipment’s operating performance and failure modes. This knowledge typically translates into a higher first-time fix rate (FTFR) and longer mean time between failure (MTBF) compared to work by on-site, general-purpose technicians. With condition monitoring, the OEM can provide repairs to reduce unplanned downtime to near-zero levels.

Without IoT for remote asset health monitoring, it is impractical for the OEM to maintain critical equipment. When the equipment failed, the OEM or its local dealer would be called with an urgent request for a technician. The first field service visit typically becomes an inspection to assess the problem and determine the needed parts, tools, and skills. A second field service visit is needed for the repair. With two service calls, the unplanned downtime could easily extend for multiple weeks. For most equipment, the negative impact on production and revenue is unacceptable.

Using remote asset health monitoring services for PdM, the service provider can identify and repair the problem before unplanned downtime occurs. The proactive repair and high FTFR avoids lost revenues for the manufacturer. This improves customer satisfaction at the executive level with high likelihood of repeat sales. Elevator manufacturers report their FTFR rose from 65 percent to over 90 percent using IIoT and PdM.

PdM and the associated business process automation make both the cost and timing of maintenance by a service provider rather than an on-site technician more attractive. Consider the combination of remote monitoring, alerts prior to failure, repair schedule optimization, one-pass repair, high FTFR, faster mean-time-to-repair (MTTR), and a significant portion of repairs performed via the web without a service call. Meanwhile, equipment continues to become more complex and a large portion of experienced technicians are retiring.

IIoT also offers the ability to deliver a more holistic view of the customer experience beyond failure prevention. More recently, OEMs have expanded their remote monitoring service to include guidance for improving the operating performance. This includes improving equipment parameters and identifying specific operator training needed to avoid poor practices.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client please Contact Us

Keywords: Servitization, Digital Transformation, Field Service, IoT, OEM, ARC Advisory Group.