The Internet of Things (IoT) has enabled new business models for original equipment manufacturers (OEM). Servitization replaces the single transaction for delivery of a product with continuous service while improving the customer experience throughout the lifecycle of an asset. The OEM benefits with a stable sales volume, new revenue sources, higher-margin repeat sales, and increased profits. Users obtain higher equipment reliability, improved operating performance, and less dreaded unplanned downtime.

The business model for servitization is equipment-as-a-service (EaaS) which has characteristics of bundled renting, support, maintenance, and a service level agreement (SLA) with improved outcomes for the user. This extends through the operating life of the asset with remote, IoT-enabled condition monitoring services and onsite maintenance. It can include support for choosing the configuration for the user’s application, and installation.

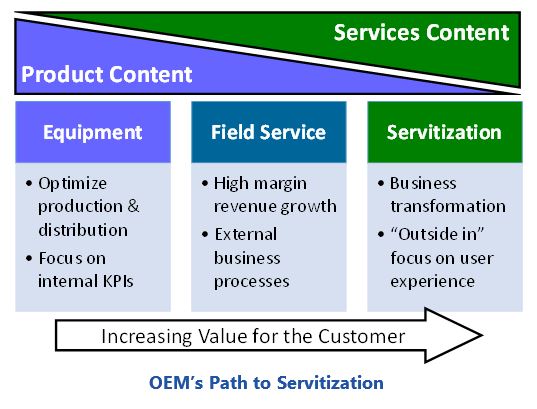

The OEM extends its business from design, manufacture, and distribution to become an integrated product and service offering. For the OEM, this requires moving from an internal cost optimization ethos to a more customer-centric, “outside in” culture. The new business model and change management become the key challenge for executives.

Many equipment manufacturers have dealers and resellers that provide reactive maintenance services to the end user. With servitization, this ecosystem moves to a proactive and more comprehensive service model. In addition to the product itself, this offering includes a variety of services needed by the user to achieve the desired outcomes. This change in business model from product to outcomes defines servitization.

Servitization applies to equipment or independent systems particularly where service requires significant product knowledge and training (like a farming harvester or an aircraft engine). It does not apply to components that are integral parts of (or embedded into) a larger system like an integrated circuit or a control panel attached to a packaging machine.

Servitization provides the user with the benefits of operating the equipment without the related burdens and risks of ownership. These burdens include financing, condition monitoring, preventive maintenance, performance optimization, and staffing trained maintenance technicians onsite to make repairs when needed. EaaS is typically an annual contract with monthly payments. Alternate business models include usage (amount of product produced), and performance-based (uptime and/or yield) versions.

Servitization extends the buying transaction from a one-time sale for product acquisition to a sustained, long-term relationship. Services become an inseparable component of the product; they are combined for a vastly improved overall user experience.

A maturity model provides a framework to evaluate an organization’s progress along a strategic initiative. This model helps organizations recognize where they are along the path towards successful servitization.

Huge differences exist between a traditional manufacturing firm and one that sells performance. A maturity model helps avoid organizational misalignment and perhaps self-destruction.

At the lower levels of the maturity model are organizations that optimize internal processes for development, production, and supply chain management, and reactively support their installed base products. The higher levels of the model involve owning and maintaining the equipment with proactive customer-supportive processes and customer satisfaction-centric KPIs. As a firm moves up the maturity model, the asset ownership transitions from the end user to the OEM. At these higher maturity levels, digital twins of the physical equipment become essential.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Servitization, Maturity Model, OEM, EaaS, FSM, ARC Advisory Group.