ARC Advisory Group recently attended the 44th annual Honeywell Process Solutions Users’ Group (HUG)

HPS President John Rudolph introduced two major offerings intended to streamline and advance the digital transformation initiatives of industrial customers. The first, Honeywell Forge for Industrial, provides actionable recommendations coupled with potential economic impact to speed appropriate business and operations decisions. Leveraging process and asset digital twins as well as comprehensive, role-based analytics, Honeywell Forge allows enterprise-wide visibility to the information and helps personnel sustain the overall performance of processes, assets, people, and safety.

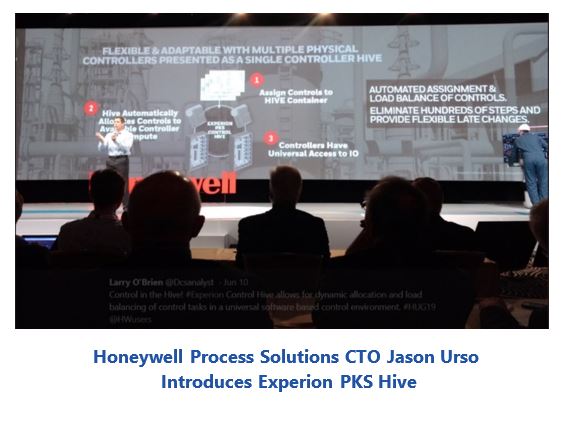

The second, Experion PKS HIVE, represents a new approach to engineering and maintaining industrial control systems. Experion PKS HIVE simplifies control system design, implementation, and lifecycle management by decoupling I/O module assignments and control strategies from specific controllers and leveraging IT capabilities in existing data centers. It also helps increase employee visibility into their impact on overall process and business performance.

CTO Jason Urso and his team brought attendees up-to-date on the company’s almost dizzying array of new solutions. The two biggest announcements were Experion PKS HIVE and Honeywell Forge for Industrial. ARC Advisory Group is preparing separate reports on these, but we provide a synopsis here.

Experion PKS HIVE builds on the LEAP philosophy of leveraging Universal I/O, standard cabinets, virtualization, virtual engineering environments, and automated commissioning. Experion PKS HIVE makes the system more modular, easier to design and configure, and adds digital twin-based commissioning. It consists of three components: Experion PKS IO HIVE, Experion PKS Control HIVE, and Experion PKS IT

The preconfigured Experion PKS IO HIVE network is based on Honeywell’s Fault-tolerant Ethernet (FTE) control network technology, with each cabinet having its own built-in firewall supporting encrypted communications. The system supports Universal IO Discovery and any C300 can access any IO channel on the network. The network interface modules in the Experion PKS IO HIVE cabinets allow local control in the field with execution rates as quick as 20ms. These network interfaces also support peer-to-peer communications, making it possible to have an entire system with no C300.

Each cabinet also includes a universal wireless hotspot that can support wireless instrumentation and connected workers. The system supports modular commissioning independent from rest of the system using a virtual controller hosted on laptop. This is helpful for packaged equipment or projects being assembled in multiple locations.

Experion PKS Control HIVE describes multiple C300 controllers acting like a single virtual controller or a control mesh. Users can assign control schemes to the Experion PKS HIVE and the system determines the best physical host, enabling automatic controller load balancing. The software-based virtual controller functions independently of hardware (PC or C300 universal control). This functionality will be available in December’s release.

Experion PKS IT HIVE leverages thin-servers to centralize management of Experion servers within a data center. It maintains the fault-tolerant architecture. Critical devices can stay on site, while the remaining hardware is centralized in the data center. The system allows for a hybrid of remote and local servers. Remote virtual machines (VM) can be replicated and available at site to guard against interruptions. Honeywell offers services to upgrade VMs. Control-as-a-service is also available through its Assurance360 offerings.

Honeywell Forge is probably the most ambitious software strategy launch in the company’s history. It

Mr. Urso presented Forge as a method to capture knowledge systemically through the models and rules. The underlying analytics allow users to connect data to knowledge and identify the distance between optimum and actual operations. Honeywell Forge allows users to leverage the design information with dynamic and empirical models and knowledge rules, forming a type of "industrial intelligence." The company also embedded its own expertise into the offering. Four solutions were mentioned: Honeywell Forge Process Reliability Advisor, Honeywell Forge Optimization Advisor, Honeywell Forge Asset Performance Management, and Honeywell Forge Profit Performance Monitor. ARC will publish a report about the latter soon.

Mr. Urso also announced a new Smart Servo tank gauging system and radar level gauge promising better accuracy, easier setup and maintenance, better regulatory compliance, and enhanced safety options.

The virtualized, platform-independent ELCN includes all LCN nodes. All PM I/O cards are now based on Experion circuit boards. Any time a customer needs to replace a failed card, the replacement will have the new electronics, which now also allows the HPMs to support the HART protocol. The EHPM is actually a combination of a C300 controller with an HPM software personality loaded. The Experion engineering packages are now unified engineering tools for both Experion and TDC/TPS devices.

Expanding on Honeywell’s connected strategy, Mr. Urso talked about Thermal IQ, a cloud-based remote monitoring system designed to monitor and manage critical thermal process data. This offering, designed to be cyber-secure, can help customers improve asset performance and, ultimately, increase plant uptime. It securely connects combustion equipment to the cloud, making critical thermal process data available in real time on any smart device.

Honeywell’s constantly expanding ICS cybersecurity offering now includes five primary solutions. All were on display at Americas HUG 2019:

ICS Shield, based on technology from Honeywell’s 2017 acquisition of NextNine, provides remote access capability to secure field assets through a single Security Operations Center (SOC). It performs asset discovery, monitoring, and patching, and automates deployment and enforcement of plantwide security policies.

Industrial Cybersecurity Risk Manager software collects information across installed assets, including network infrastructure equipment. The solution enables users to calculate risk scores presented through easy-to-read dashboards and visualization tools.

Secure Media Exchange (SMX) scans USB media for threats and enforces use of properly validated USB drives. Honeywell announced plans to eventually expand these threat intelligence capabilities system-wide.

Managed Security Services (MSS) provides turnkey security operations management for customers that prefer to augment or outsource their in-house capability with improved visibility into potential threats, extended multi-vendor support, and 24x7 coverage through global security operations centers (SOCs) located in Singapore, Bucharest, or Houston.

Security Consulting Services consist of many highly specialized offerings that customers can leverage to improve security. In addition to assessments, companies can engage the Honeywell team in architecture design reviews and test various scenarios in one of three labs located in Atlanta, Dubai, and Singapore.

Honeywell shared some sobering statistics about workplace demographics. The company estimates that roughly 50 percent of the workforce in many major process industries will retire over the next five years. The challenge going forward is to capture their expertise and experience, transfer it to the new generation of workers, and then retain those newly trained workers.

The company has invested in applications geared toward how the next generation workers learn, visually and actively. In the HUG demo center, we saw two goggle-based immersive training solutions that simulated actual work conditions and scenarios with an emphasis on “learning by doing.”

One system allowed users to interact with virtual control cabinets to perform basic installation tasks. The simulation, which allowed users to “walk” around the cabinet, was detailed enough to show labeling on components and input jacks along with a step-by-step demonstration of the install procedure. Another solution combined panel and field operator training, with visualization tools for each. Training scenarios involved the control system operator directing field workers to field devices and other assets around the “plant” to perform tasks, the effects of which could be seen in real time.

The wearable also allows field workers to connect to DCS operators via video chat with an optional hi-resolution camera. This can help compress the time needed to perform field operations or correct problems that may be identified on an inspection round or during normal day-to-day work. With video chat, field personnel can contact experts for guidance on specific tasks or issues as needed. Field operators can also use the camera to record their own step-by-step procedure videos, adding to the plant’s knowledgebase. The camera sports an infrared mode that can be used to inspect piping and other plant equipment on the spot. Other supported applications include location tracking, geofencing, gas detection, biometrics tracking, and man-down detection.

Honeywell experts also updated ARC on the company’s Measurement IQ software offering for gas pipelines (see last week’s ARC View). Designed to address the perennial problem of measurement drift over time, the software closely monitors ultrasonic flowmeter performance to help ensure accuracy to meet custody transfer standards and assess device health with an eye toward extending meter calibration cycles.

Measurement IQ provides a holistic view of a company’s flowmeter operations and performance, a summary of meter diagnostics, and trigger alarms should accuracy cross certain thresholds.

Honeywell announced several enhancements to the system, including support for third-party (Daniel and Sick) meters, a function to determine real-time meter uncertainty, improved cybersecurity measures, and field-deployable unit with ATEX, IECEx, and NEC certifications.

ARC recommends that all technology users learn to use available tools to the fullest. Given the difficulty finding staff, it is important that the available staff understand what represents success in their role(s) and understand how it is measured. Do the right people in the organization have the right information at the right time? Software like Honeywell Forge enable organizations to facilitate processes and support effective decisions that increase competitiveness in multiple dimensions.

Honeywell continues to prove its dedication to its installed base. The company has made it as painless as possible to bring its first DCS customers into its current system and leverage the benefits available. The challenge posed by the looming retirement of experienced workers will be quite daunting, but Honeywell’s program goes a long way toward digitizing the work of field operators and connecting their activities to the greater enterprise.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: HUG, Honeywell, Honeywell Forge for Industrial, Experion PKS HIVE, Cybersecurity, Connected Worker, Measurement IQ, Thermal IQ, Terminal IQ, AR, VR, Training, Mobility, Wearables, Connected Plant, DCS, Control, Assurance360, Honeywell Forge for Cybersecurity, Honeywell Forge Cybersecurity Platform, ARC Advisory Group.