ARC Advisory Group recently conducted a web-based survey to gain an external perspective on best practices and strategies for issues related to Manufacturing Software and Services Capabilities. This PowerPoint report summarizes the survey results and provides a summary of MES software and services and recommendations for ARC Advisory Service clients.

Survey Participants - MES Suppliers’ Profile

- Mix of both process and discrete suppliers; mix of different suppliers focused on

various industries

various industries

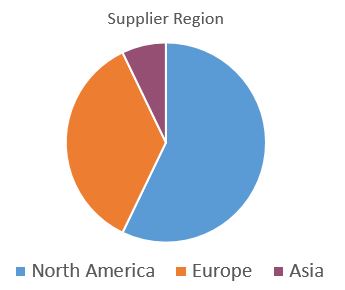

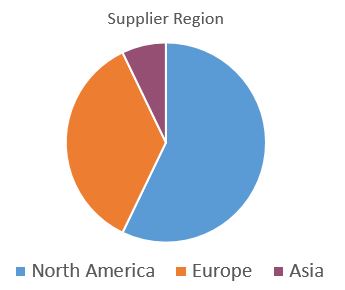

- Participants were mostly from North America and European regions but at least 75% of the suppliers that took the survey are global suppliers or capable of representing other regions

- Survey is from the supplier point of view based on their experience with MES solutions.

- ARC Advisory Group created and executed the survey for the benefit of its MES supplier clients (but the survey results also provide useful insights for end user clients).

ARC’s Definition of Manufacturing Execution Systems (MES)

MES software manages production and operations, including the rules, workflow, and information required to execute and document the operational processes to convert raw materials into finished products. The software delivers intelligence to operations to help optimize production activities, improve operational efficiency, provide digital guidance, enforce workflows, and document regulatory compliance.

ARC’s definition includes multi-faceted production capabilities that improve production performance and reduce costs. Capabilities range from collaborative production, workflow enforcement, track and trace, operational intelligence, regulatory documentation, analytics, visualization and end-to-end integration to other technologies such as supply chain, automation systems and ERP systems.

MES Capabilities

Capabilities vary by MES industry and regional focus. Some MES solutions are sold as part of a different solution or sold using a partner. Some capabilities e.g. batch are applicable to certain industries.

There are many different applications built into MES. Other findings include:

- Resource management (equipment, time & labor) is the strongest capability in many MES solutions.

- Data collection and storage is the second strongest capability.

- Regulatory compliance management is third.

- Fourth is energy management. End users are more interested in Energy management seems to be more popular when energy prices rise.

- Fifth is quality management.

Other capabilities mentioned include digital twin of the factory, having equipment and IoT integration layer (similar to MES platform integration layer), order management, change management, advanced operator UI, special work order requests, ERP integration, inventory management, kitting verification, connectivity to machines, sensors, business systems, PLM warehouse, in process testing automation, supply chain enablement, contract manufacturing management, 3PL enablement.

Cloud Offerings for MES

- Almost all suppliers have a cloud offering for MES

- 32% of respondents have a single tenant private cloud/SaaS offering

- 23% of respondents have a multi-tenant public cloud/SaaS offering

- 23% have on-premise, cloud and hybrid offering

- 18% have on-premise hybrid cloud single and multi-tenant offering

- Only 4% of respondents offer a hybrid cloud (single, multi or private cloud)

Operating Systems Offered by Suppliers

- Microsoft Windows operating system is used between 75 to 100% of the time, followed by Android which is used from 25 to 75% of the time and Apple IoS, is used 10 to 50% of the time. The latter two are mostly offered for mobile platforms.

- UNIX is used from 10 to 25 percent of the time.

- Others mentioned having HTML 5 for use with any platform including mobile devices.

- Other respondents mentioned that their application works with any browser.

- Others considered this proprietary information and did not disclose.

What changes are you seeing that impact MES?

- New MES platforms to connect data and IoT.

- By connecting data and assets, companies are making better informed decisions on an enterprise level.

- Use of OPC UA standard as our internal data protocol for security and connectivity for on-premise and cloud

- Better interoperability.

- MES will be more connected and provide more information for increased collaboration, integration of assets and data, and remote cloud-based services that allow subject matter experts (SMEs) to support applications and production in any location due to the process and data visibility.

Table of Contents:

- Respondent Profile

- Survey Results (one/two slides per question): charts, ARC analysis and respondent comments

- Most Important Selection Criteria

- What’s driving market growth

- Architecture, Cloud providers, Operating systems…

- Toolkits

- Future capabilities

- Changes impacting MES

- Findings

- Best practices, strategies & recommendations for end users and suppliers (two slides):

- Appendix: Survey Methods

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

various industries

various industries