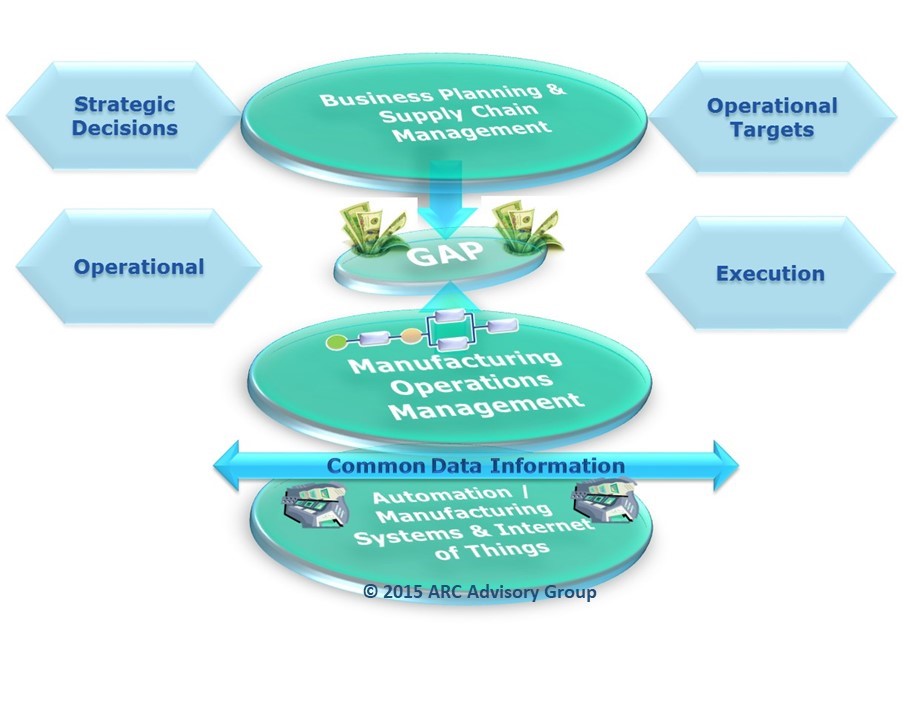

Driven by the digital transformation trend, the next-generation of manufacturing operations management (MOM) and manufacturing execution systems (MES) software is impacting manufacturing and production. Today’s manufacturing products are becoming more personalized and need to adapt faster to changing supply and demand. Tighter production specifications, greater economic pressures, more stringent process safety measures, cybersecurity standards, and environmental regulations are triggering manufacturers to implement new generation manufacturing operations management (MOM) and MES technologies.

Today's MOM systems address a wide range of industrial applications including operational historians and real-time databases, batch management, plant asset management, quality management, planning and scheduling, offsite automation, and more. Coordinating an effective MOM implementation is a key challenge, not only from a software implementation standpoint, but also from a business value and lifecycle management view. Many end users struggle to use their MOM implementations effectively and poor work processes can also hamstring the technology's potential value. What's more, the best-of-breed approach many organizations use for their MOM implementations often requires extensive integration and custom engineering which is why it is important to select the MOM and MES solution carefully.

Managing these challenges requires new technologies that enable agility and flexibility, and the ability to collaborate with many different systems, data sources and collaborative processes. Newer technologies enable the ability to obtain better process visibility and reduce downtime with better intelligence for actionable real-time decisions.

Choosing the best technology and path forward for operations management, for your circumstances, can be difficult and time-consuming. To help you in this task, ARC delivers global market intelligence, best practices, technology and supplier selection guides and other market research for topics such as: Operational Excellence (OpX), Overall Equipment Effectiveness (OEE), Process Optimization, Manufacturing Execution Systems (MES), and Asset Management. ARC's industry leading experts closely monitor operations management solutions from major suppliers around the world.

In ARC's view, to maximize end user business value, potential partners must be evaluated not just on their ability to execute the project, but also for their knowledge of a broad range of industry applications and technologies from different suppliers, their ability to employ standards and best practices, and employ a true lifecycle approach.