The ISA-101 Standard acknowledges the many opportunities to reduce complexity, customization, and cost in Human Machine Interface (HMI) across the plant lifecycle. HMI goes beyond just graphical design and the way information is presented to the operator. HMI engineering and configuration tasks, for example, can greatly add to project cost and complexity. Even today with the new tools and approaches offered for HMI, many end users will spend up to $10,000 or more to develop each page of HMI graphics for their process operations.

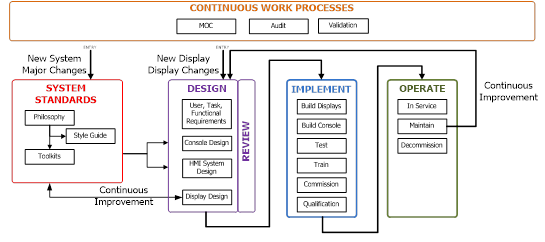

As a true lifecycle-based standard, ISA-101 defines how to best use technologies through all phases of the HMI lifecycle, from design through implementation, operations, and maintenance. Some examples of lifecycle-based standards in the process industries include the ISA 18.2/IEC 62682 standard for alarm management and the ISA 84/IEC 61508 and 61511 standards for process safety.

The ISA-101 standard takes a similar lifecycle approach for HMI lifecycle management, from developing HMI standards and design, through HMI installation and maintenance. The standard provides guidance to “design, build, and maintain HMIs that result in more effective and efficient control of the process, in both normal and abnormal situations.” It also aims to improve the operator’s ability to detect, diagnose, and respond to abnormal situations in a timely and effective manner.

Many end user organizations face large migration and modernization projects as well as an increasingly diverse installed base of systems. During the standards development phase of these projects, it’s important to establish a unified HMI philosophy with documents that set the foundation for all HMI design decisions. ISA-101 provides guiding principles for HMI design that are independent of vendor platforms, including human factors engineering guidelines, standards, best practices, functional requirements, and experience. ISA-101 also allows users to develop common HMI style guides by providing HMI implementation details that are viable for all supplier platforms.

ISA-101 covers all hardware and software aspects of the HMI in the design phase, including identifying requirements and initial designs for all HMI components. In addition to user, task, and functional requirements, ISA-101 can help users in their overall HMI system design, console design, and display design. For end users, this results in more effective requirements documents, better HMI system design specification, console design documents, and display design documentation.

ISA-101 implementation phase efforts cover the detailed work to actually build the HMI in the target platform and hardware. It also includes requirements for testing, documentation, and training.

In the operations phase, ISA-101 covers management of change and requirements for HMI operations, maintenance, and decommissioning.

The draft of the ISA-101 standard began as a topic-based outline document. These outlined topics eventually evolved to become the subjects of the standard clauses. After many years in development, the ISA Standards & Practices board approved the standard in early 2015. ISA-101 subsequently became an internationally recognized ANSI/ISA standard upon gaining ANSI approval in July, 2015 as the ANSI/ISA-101.01-2015 Human Machine Interfaces for Process Automation Systems.

Current ISA-101 activities include development of an HMI Philosophy & Style Guide Technical Report, which is currently being pursued by Working Group 1 (WG1) in the standards committee. This technical report will describe example applications of the Philosophy and Style Guide to various process automation systems use cases, and will be platform independent. In addition, a second work group, WG2, is pursuing HMI usability and performance issues. The report generated by this working group will be used to assess the effectiveness of HMI applications and how the standard can help improve related metrics.

The standard will also address HMI for mobile devices, an increasing concern across industry today. In the earlier days of ISA-101, mobile- and machine-based displays were out of scope, but these technologies have evolved rapidly and are becoming common in plants and manufacturing facilities. Working Group 3 (WG3) of the ISA-101 committee was formed to investigate mobile HMIs. WG3 will develop technical reports to evaluate and define the use of mobile devices as HMI stations; and how to effectively implement an HMI for use on a mobile device. ISA-101 also formed a Working Group 4 (WG4) to investigate HMIs for machines.

ISA-101 specifies several types of HMI displays in three primary groupings, as follows:

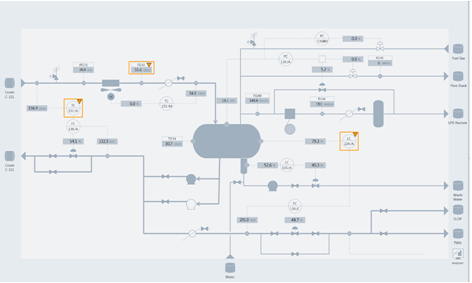

Level 1 or Level 2 displays should be based simply on P&IDs, as many are today, but focus on operator’s realm of control and KPIs. Overview displays should provide a concise but informative status of the process. Most plants today don’t have L2 or L3 displays and many end users do not know how to design and develop them. ISA-101 provides a style guide as well as other guidance on building more effective displays that go beyond simple graphical representation of the process.

The practices defined in ISA-101 are intended to apply to continuous, batch, and discrete processes. ARC believes the standard offers a lot of value for end users, including many opportunities to reduce the cost of HMI throughout the lifecycle, improve operator effectiveness, and reduce plant incidents. Unlike other standards in the past that have attempted to define distinct pieces of technology, ISA-101 provides a roadmap for end users to implement an effective HMI lifecycle strategy regardless of the kinds of technology they use.

ARC will continue to report on developments in this important standard as well as other standards by International Standards Bodies and Associations that relate to Industrial Best Practices.