Organizations in the process industries (refining, chemicals, petrochemicals, etc.) face clear and relentless pressure to improve profitability while managing operational risk, maximizing asset integrity and reliability, and enabling operational discipline. What is not so clear is how these industrial organizations can take advantage of new technologies and an intelligent operations approach to gain more value from their data, assets, workforces, and value chains.

Operational excellence (OpX), a prerequisite for world-class business performance, provides the foundation for a company’s standard for operations, enhanced compliance assurance, conduct of operations, workforce competency, and asset performance management. Many industrial organizations operate in environments that present a potential risk to workers, the environment, physical assets, and/or the business itself.

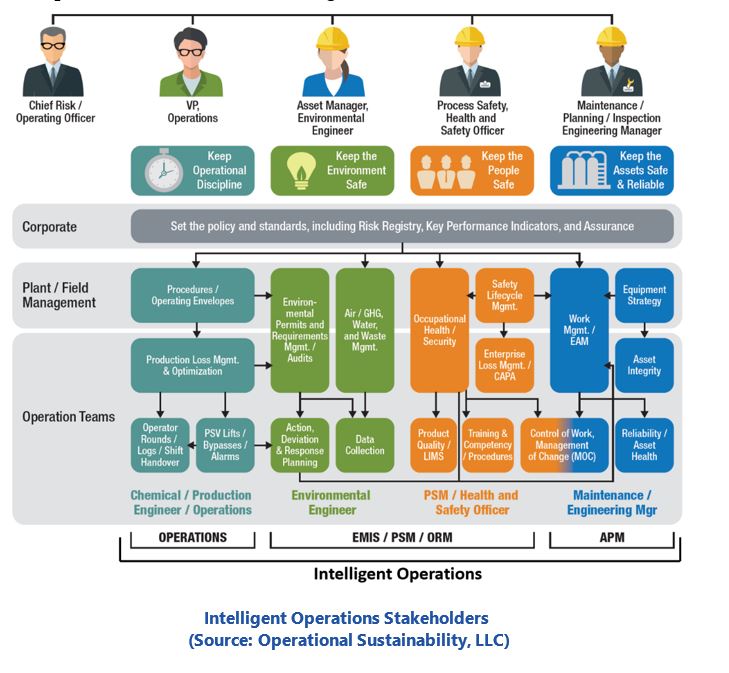

Most industrial process companies globally will undergo some degree of digital transformation in the coming years. Many are actively piloting emerging technologies. However, many companies today tend to focus efforts on acquiring the technology itself, without considering the full organizational impact that processes and practices will play in the outcome. This impacts multiple stakeholders within an organization (see chart above).

Operational Sustainability LLC believes that intelligent operations requires an integrated solutions platform designed to enhance supporting processes for OpX. This approach aggregates data, reduces complexity, and enables agility as technology changes and embedded artificial intelligence captures “know-how” in applications to further automate operational processes. Ultimately, an intelligent operations platform supports

To achieve and maintain world-class business performance, many companies find it helpful to create one system of record across diverse applications and data sets. The intelligent operations approach helps companies avoid conventional technology overhauls that require “rip out and replace” to enable the required interoperability. Today’s modern platforms enable companies to more readily integrate by leveraging cloud computing and related apps to enable rapid deployment of platform modules and acquire and analyze data from across the system more quickly.

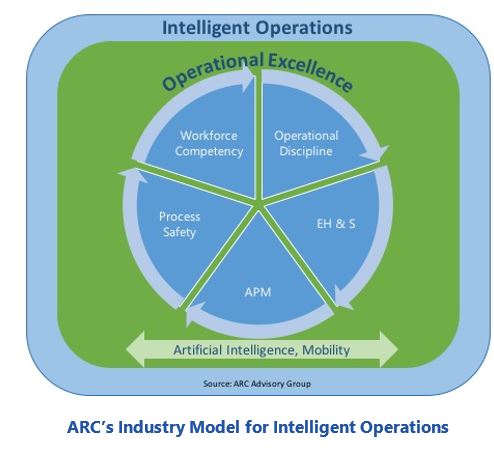

The first steps along the road to intelligent operations are to first identify the key applications, data, measurements, and processes to standardize and then enable those processes with the data needed to optimize processes and assets. According to the company, intelligent operations have the following core elements:

These elements line up well with ARC’s own industry model for intelligent operations (see graphic).

Most companies need a significant technology transformation to achieve intelligent operations due to having numerous and often redundant siloed applications. This transformation often involves replacing older software applications with a more agile, standardized platform to support dynamic processes and changes in their business. Companies also are moving toward software-as-a-service (SaaS) and relying upon data connectors to simplify integration beyond what traditional on-premise applications allowed.

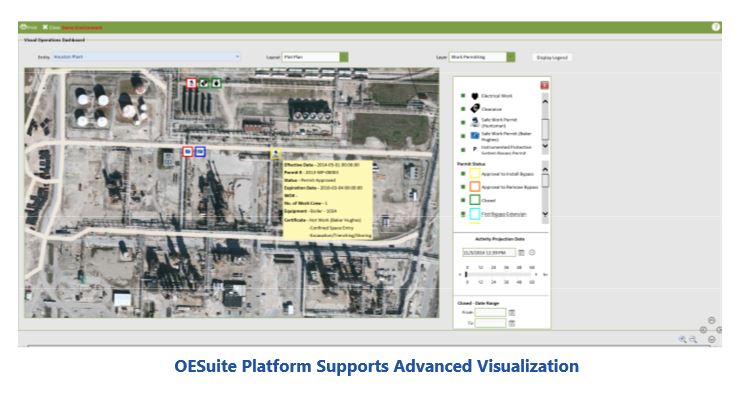

The transformation toward a modern, flexible digital architecture requires making better use of data and analytics to provide all workers with personalized insights, including establishing a digital foundation to share knowledge across the enterprise. The OESuite platform, for example, has an asset registry as its foundation and a common suite of mobile applications to make it easier to drive user adoption through a common user interface.

As we learned, the OESuite offering from Operational Sustainability, LLC was designed to provide a relatively comprehensive (more than 40 modules), enterprise-wide platform that can help industrial organizations manage operational risks, enhance compliance assurance, enable conduct of operations, and minimize equipment downtime.

The platform aggregates information to support visualization of the underlying metadata to enable point-and-click drill-down from a facility map or aerial view, all the way to an individual pump. Employees who need to work on that process chain, or specifically on that pump, can access actionable information in real-time as asset conditions change from shift to shift. Operational Sustainability, LLC believes that a system that delivers in-formation at the point of work is a key piece of the intelligent operations “puzzle,” since it can help organizations ensure that:

Most industrial organizations today have room for operational and asset improvements. Departments typically operate independently through fragmented, and often overlapping, management systems that lack the granularity to enable effective execution. Much information is stranded in silos with a lack of master data governance and thus poor interoperability and ineffective decision support. Clearly, moving to an intelligent operations model could help define a path to enable the kind of dynamic decision support that keeps organizations in compliance and operating in the black.

Most companies require a technology transformation to achieve intelligent operations. However, the initial stages of transformation need to be led by assessing and aligning management and cultural systems.

While it’s possible to assemble a technology solution set from multiple suppliers, this can introduce significant integration challenges and result in poor work process execution. Hence, it may make sense for many industrial organizations to partner with a single technology supplier, such as Operational Sustainability, LLC, that can also help address that company’s operational and cultural challenges along this challenging (but often highly rewarding) journey.

OESuite is a trademark and Operational Sustainability, LLC is a registered trademark of Operational Sustainability, LLC. All other trademarks mentioned are the property of their respective owners.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Intelligent Operations, Operational Excellence, Digital Transformation, Digitalization, Process Safety, EH&S, Competency and Training, Asset Performance Management, Operational Risk Management, Safety Lifecycle Management, Conduct of Operations, ARC Advisory Group.